When it comes to vehicle maintenance and repair, knowing how each part functions and connects is crucial for smooth operation. A detailed schematic guide can provide clear insights into the structure and arrangement of different components, ensuring that you can easily identify and address any issue that arises.

Whether you’re handling regular upkeep or troubleshooting a malfunction, a comprehensive visual representation of the machine’s interior allows for a more efficient approach. These guides serve as an essential resource for anyone looking to improve their technical understanding or perform repairs with confidence.

Having access to an organized and easy-to-follow chart helps simplify the complex task of fixing or replacing individual pieces. It gives both professionals and enthusiasts the clarity they need to restore vehicles to peak performance quickly and effectively.

Understanding the Vehicle Component Blueprint

In order to efficiently manage the maintenance and repair of a vehicle, it’s essential to have a clear understanding of its internal structure. A comprehensive visual guide that shows how each component fits into the larger system is indispensable. Such a reference not only aids in identifying parts but also in understanding their function and how they interact with other elements.

Why a Component Blueprint is Necessary

When troubleshooting or replacing damaged parts, having access to an accurate visual layout significantly improves the process. Without it, finding the right component could be time-consuming, especially for complex machinery. Here’s why these guides are essential:

- Clear identification of each component

- Easy tracking of connections and interrelations

- Reduced risk of errors during repairs

- Increased efficiency in performing maintenance tasks

Key Features of an Effective Blueprint

An ideal guide will include several important features that help users quickly locate and assess the parts they need to work on. These elements are typically designed to be intuitive and straightforward:

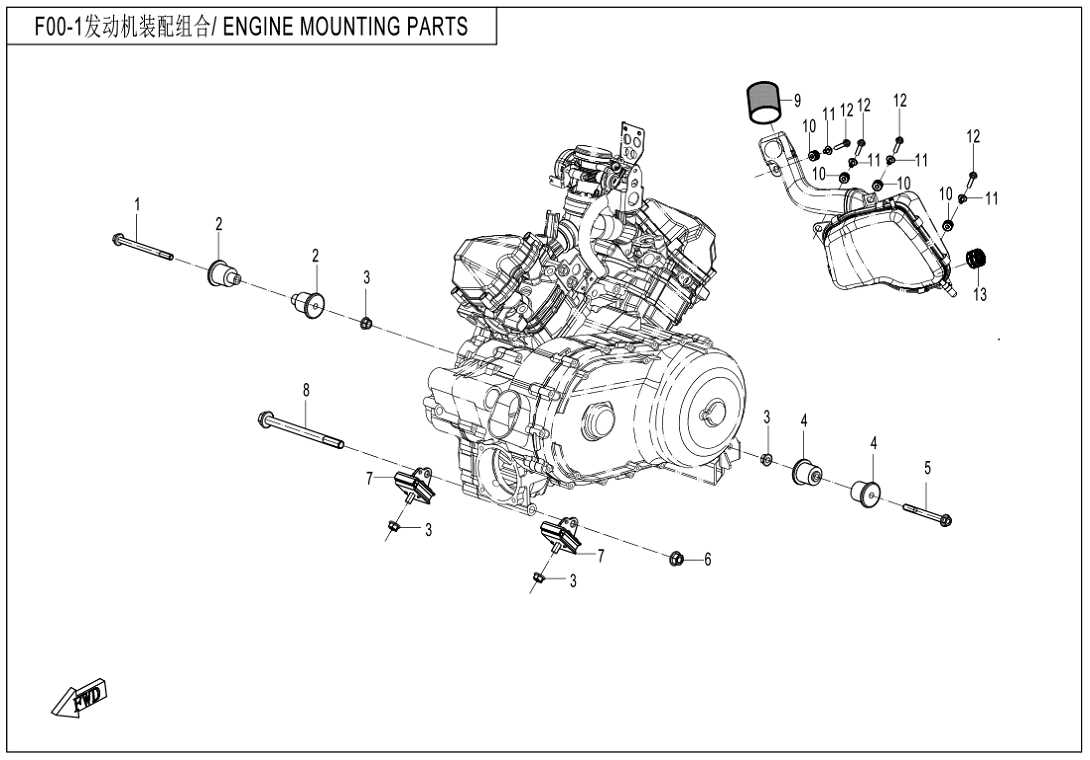

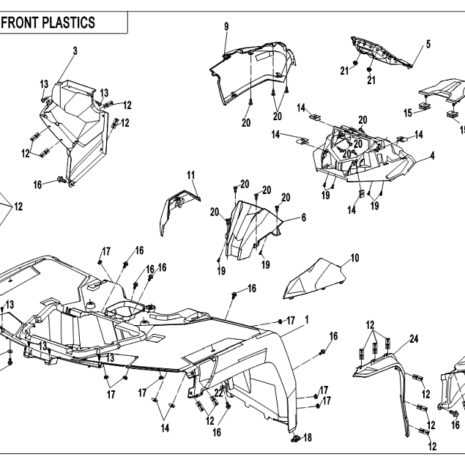

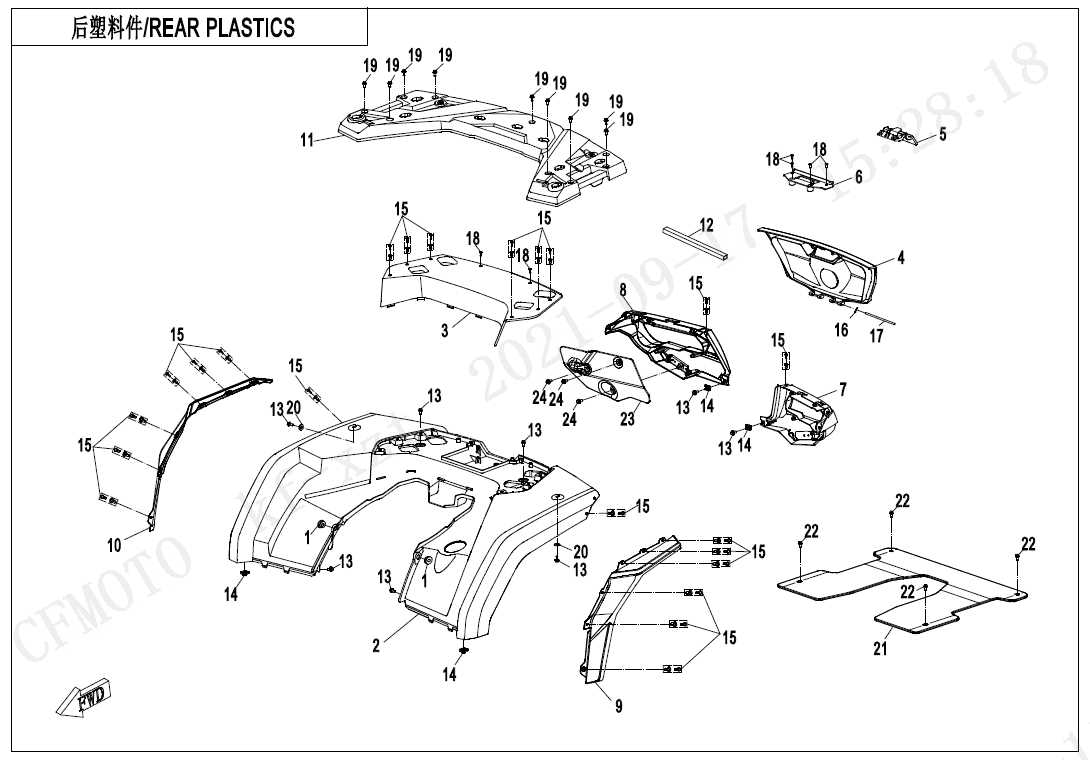

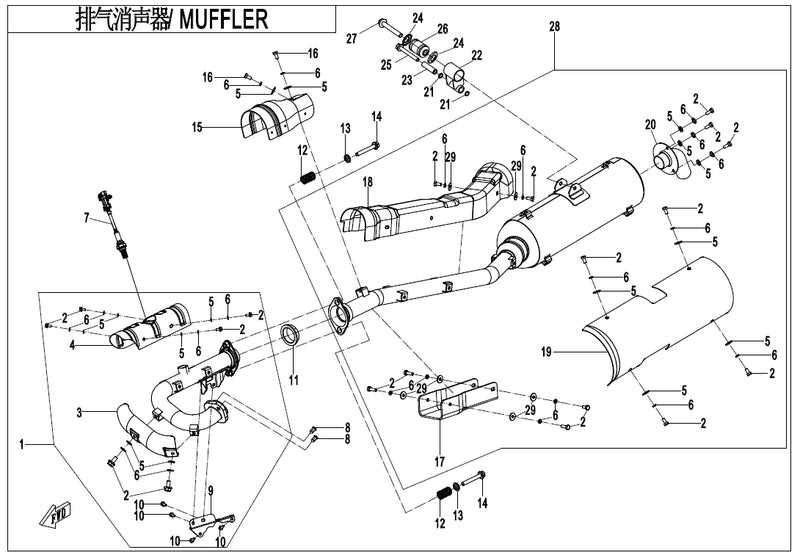

- Labeling: Clearly marked components with names or reference numbers.

- Connection Details: Information on how parts are connected or interact with each other.

- Component Variations: Distinguishing different models or types within the same family of machines.

- Exploded Views: Diagrams showing components separated for easier identification.

How to Use the Blueprint Effectively

To maximize the benefits of a detailed vehicle layout, it is crucial to know how to interpret and apply the information provided. A well-designed schematic can significantly speed up the repair process, but understanding how to read it is essential. This guide will help you make the most of the visual reference and ensure that your maintenance tasks are carried out efficiently.

Start by familiarizing yourself with the overall layout. Take note of how each section is organized, and understand the logical flow between different components. Identifying the key areas that need attention or repair will be easier once you grasp the general structure of the machine.

Next, pay attention to the labeling and reference numbers that accompany each component. This information is crucial for ordering the correct replacement parts and ensuring compatibility. By cross-referencing the guide with your vehicle, you’ll be able to pinpoint the exact locations of damaged or worn-out elements.

Lastly, make use of the exploded views, which separate the components for clearer visibility. This can be especially helpful for disassembly and reassembly, ensuring that you don’t overlook any necessary steps. By following this structured approach, you’ll be able to tackle repairs and maintenance with greater confidence and precision.

Common Issues and Troubleshooting with Vehicle Components

When performing maintenance or repairs on a vehicle, it’s common to encounter issues that require troubleshooting. Understanding the typical problems associated with different parts is the first step in diagnosing and resolving these issues. Recognizing the signs of wear or malfunction can save time and prevent further damage to the machine.

Identifying Common Problems

Several issues can arise during the use of a vehicle, and knowing how to identify them early is crucial for successful repairs. Some of the most frequent problems include:

- Worn-out or damaged components causing malfunction

- Loose connections leading to erratic performance

- Incorrect assembly or improper alignment affecting function

- Clogged or deteriorated parts impacting efficiency

Steps to Troubleshoot Effectively

Once a problem is identified, the next step is to troubleshoot effectively. Follow these steps to ensure a smooth repair process:

- Consult the layout to locate the exact component that may be causing the issue.

- Examine the part for any visible damage, wear, or misalignment.

- Check for any loose connections or missing fasteners that could cause malfunction.

- Replace or repair the damaged part according to the specifications in the guide.

By following these steps, you can efficiently identify and resolve issues, ensuring your vehicle runs smoothly and reliably.