Understanding the intricate components within mechanical air systems is essential for proper maintenance and efficient performance. Each element plays a vital role in the overall functionality, contributing to the smooth operation of the entire unit. Identifying and comprehending how these elements interact is key to ensuring long-term reliability and addressing potential issues promptly.

Detailed visual representation of these internal elements provides a clearer understanding of their positions and interconnections. This knowledge is beneficial for anyone looking to troubleshoot or replace individual components without the need for professional assistance. Proper familiarity with these parts enables better decision-making when it comes to upkeep and repair.

Recognizing common wear and tear signs in specific elements can significantly enhance the lifespan of the system. Understanding the design and function of each piece allows for proactive management, ensuring optimal performance and reducing the likelihood of failure.

Understanding Internal System Components

Every complex machine consists of various interconnected elements, each playing a crucial role in maintaining its functionality. Familiarizing yourself with these components allows for better troubleshooting, maintenance, and repair. Each part contributes to the seamless operation of the unit, and understanding their specific roles ensures that the system runs efficiently and effectively.

Key components within the system include the core mechanisms responsible for energy conversion, airflow regulation, and pressure management. These elements must work in harmony to ensure the unit performs at its optimal level. Knowing their functions and interactions is essential for anyone handling repairs or performing regular upkeep.

Recognizing early signs of malfunction in any of these key parts can prevent more significant damage. By learning how each component behaves under normal conditions, it becomes easier to spot issues before they escalate, saving both time and resources.

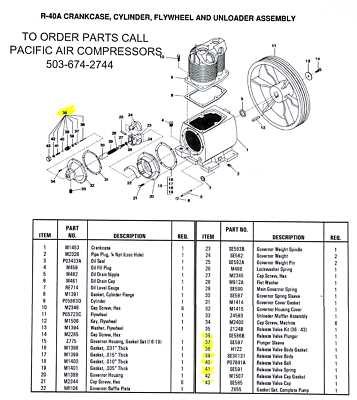

Detailed Illustration of Key Components

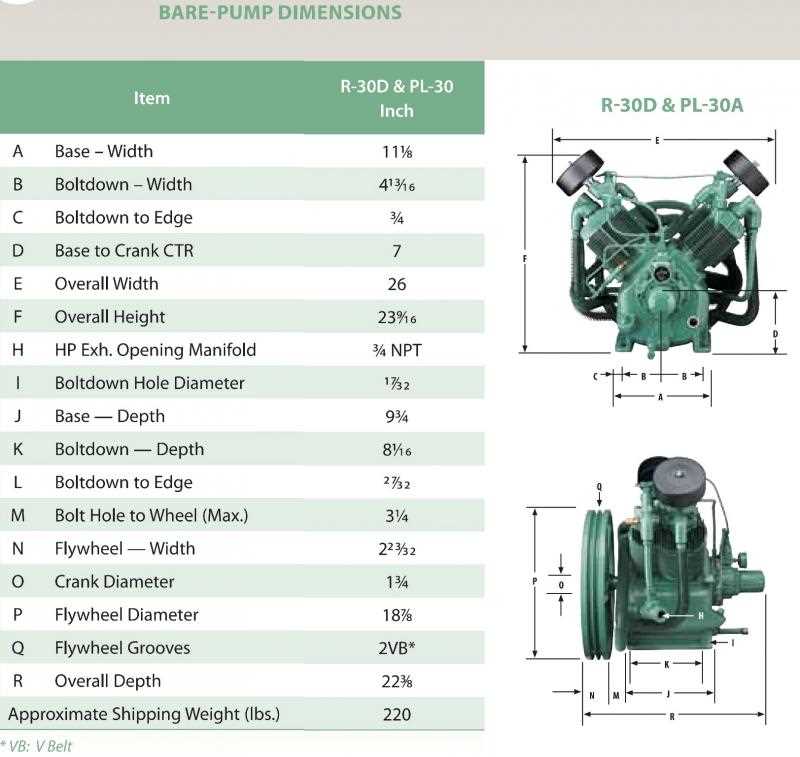

Having a clear visual representation of a system’s essential elements allows for a deeper understanding of how each part contributes to its overall function. These illustrations serve as a helpful tool for anyone looking to familiarize themselves with the inner workings of the machine, offering a closer look at the placement and relationships between various components.

Each key element is carefully depicted, showing how they connect and interact with one another. This clarity helps in identifying specific areas that require attention, making it easier to pinpoint potential issues. Visual aids like these are particularly useful when conducting maintenance or preparing for repairs, as they highlight the layout and positioning of the most important components.

When studying these representations, it’s important to pay attention to the design and flow of the system. Understanding the placement of each part ensures that anyone working with the equipment can approach tasks with confidence and efficiency, ultimately leading to better performance and longevity.

How to Identify System Malfunctions

Recognizing early signs of malfunction in any machinery is crucial for maintaining its efficiency and avoiding more severe issues. By observing certain behaviors and changes in performance, one can pinpoint potential problems before they escalate. Understanding what to look for can save time, resources, and effort in repairs.

Common symptoms of trouble include unusual noises, irregular vibrations, and a drop in performance or efficiency. These can be indicators that something is wrong with one or more of the system’s critical elements. Regular inspection and monitoring are essential to catching these issues early, ensuring that the unit continues to function properly over time.

In addition to these physical signs, performance anomalies such as fluctuating pressures or inconsistent airflow can also signal underlying issues. Diagnosing these problems requires careful attention to the behavior of each component and understanding how they should perform under normal conditions.