When maintaining complex machinery, knowing its internal structure is crucial for efficient repairs and upkeep. A comprehensive visual representation can provide valuable insight into each element’s function and location. This guide explores how to interpret and use these visuals for a more streamlined approach to maintenance.

Accurate identification of each component is vital for troubleshooting, part replacement, and ensuring the equipment continues to perform optimally. In this section, we will examine how to navigate the visual reference and understand its key features, helping you manage your equipment with confidence.

Regular inspection and understanding of the internal workings allow for quicker issue identification, minimizing downtime. With the right tools and knowledge, anyone can handle basic maintenance tasks effectively, ensuring long-lasting performance.

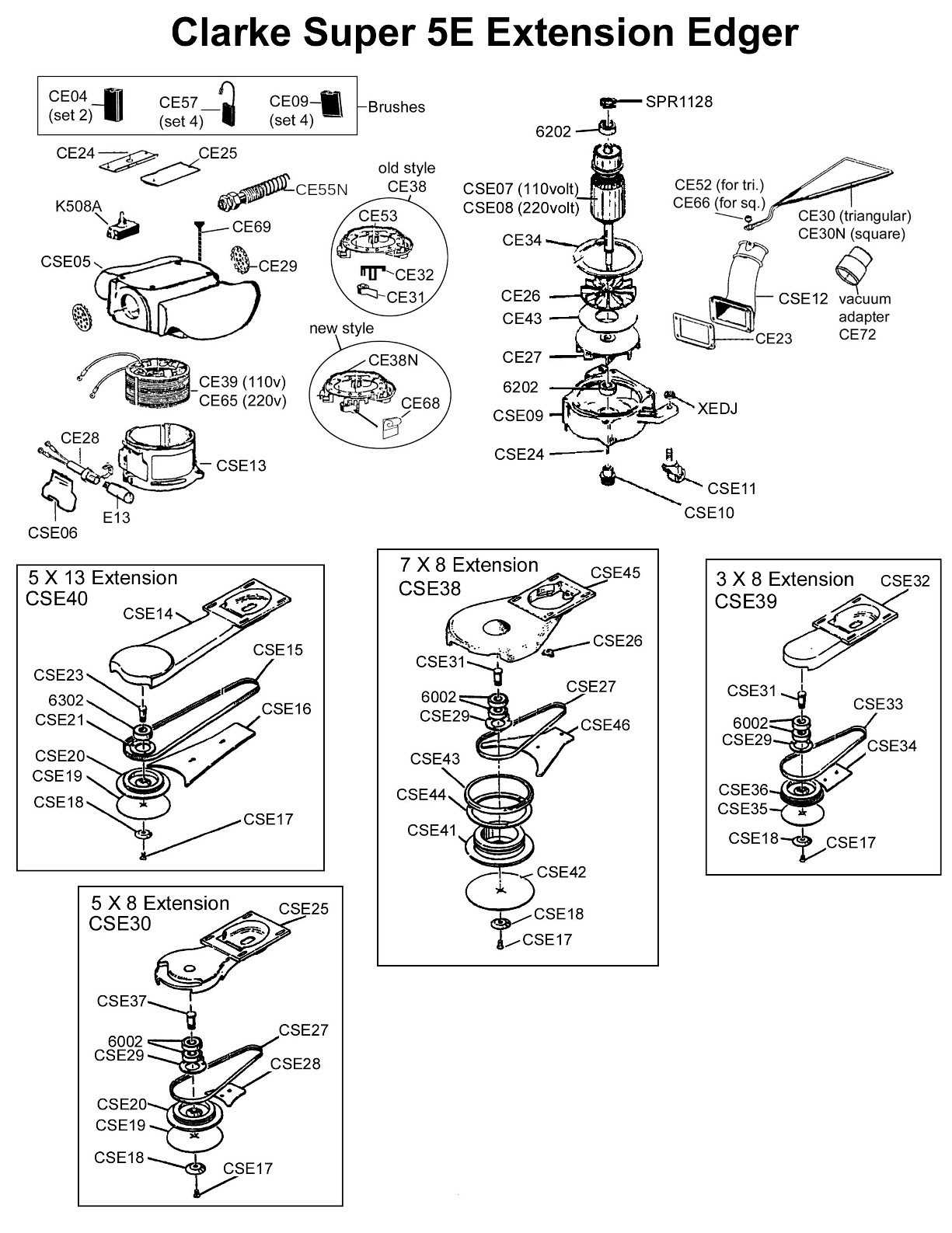

Understanding the Clarke Super 7R Edger Components

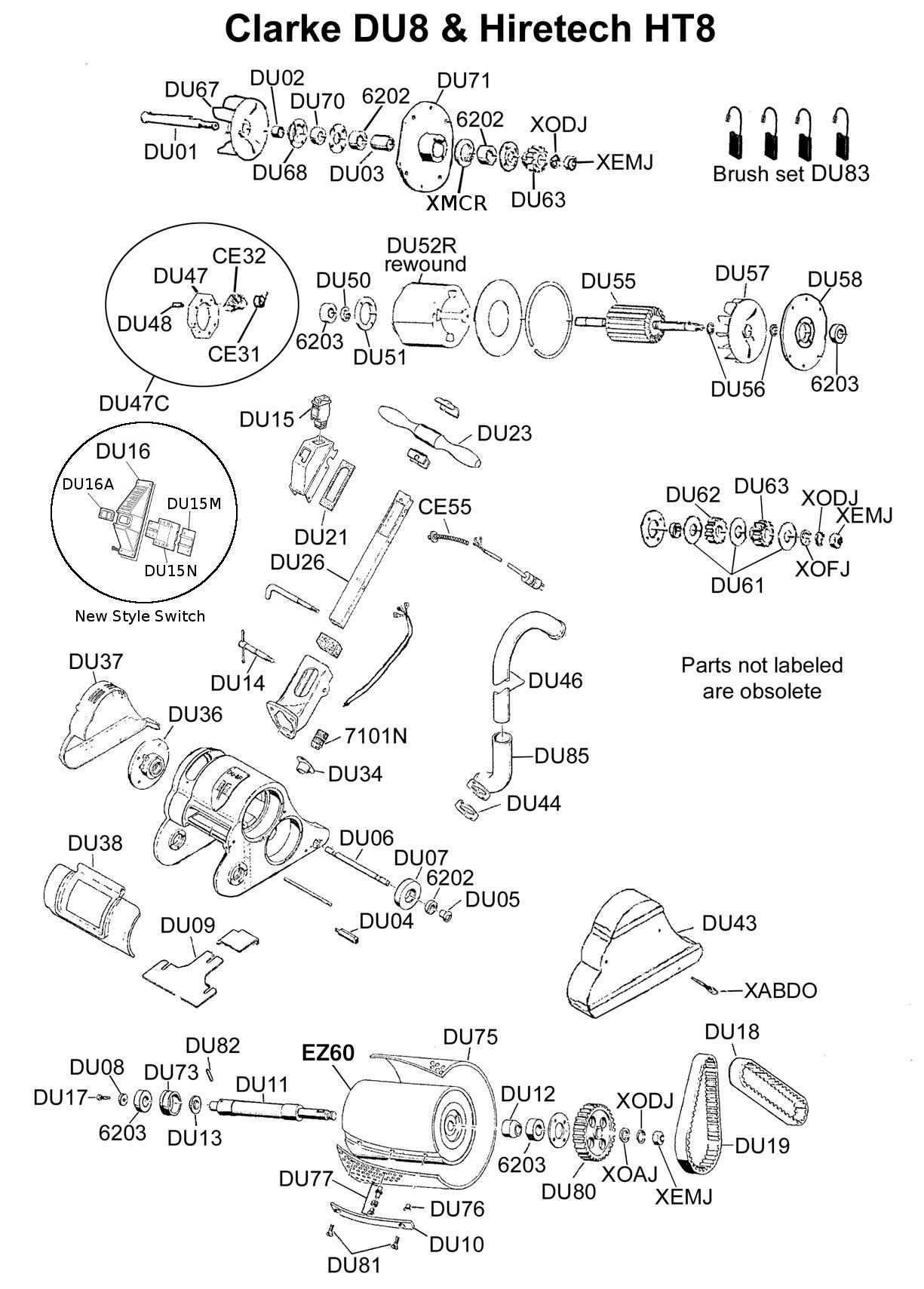

Every piece of machinery relies on a complex network of individual elements that work together to ensure proper functioning. Understanding how each part interacts with others is essential for anyone responsible for its maintenance or troubleshooting. This section breaks down the core components and their roles, providing insight into how they contribute to the overall operation of the machine.

Key Elements of the System

The core of this equipment consists of several key units that must be in perfect working condition to guarantee performance. These include the drive mechanism, the control panel, and various structural supports. Each plays a critical role in movement, safety, and user control. Knowing the layout and function of each unit allows for better decision-making when servicing or replacing worn parts.

Identifying Common Issues

Understanding the components also aids in diagnosing problems more efficiently. Issues often arise due to wear and tear on specific parts like belts, motors, or connectors. By recognizing which components are most likely to fail, maintenance can be performed proactively, reducing the need for costly repairs and extending the lifespan of the machine.

How to Read the Parts Diagram Efficiently

Having a clear understanding of an equipment layout can significantly simplify the process of maintenance and repair. Visual representations of the internal structure can guide you in identifying individual components, their functions, and how they connect with each other. This section explains the best practices for interpreting these visuals and making the most out of the provided reference.

Familiarize Yourself with the Layout

Before diving into the details, take a moment to understand the overall structure. Most visual guides categorize parts into sections based on their function or location within the machinery. Identifying the different zones, such as the engine area or the control mechanism, will help you navigate the diagram more effectively.

Focus on Key Indicators

Pay close attention to the symbols, labels, and color codes used within the reference. These often indicate the type of component or its specific function. In some cases, arrows or lines may point to connecting parts or assemblies, helping you understand the relationships between different elements. Recognizing these indicators will make it easier to locate the correct part when performing repairs or replacements.

Common Maintenance Tips for the Edger

Regular upkeep of outdoor equipment is essential for ensuring its longevity and peak performance. By following a few straightforward practices, you can prevent common issues, minimize downtime, and keep your machinery running smoothly. This section outlines some of the most effective maintenance routines that will help maintain your equipment in top condition.

Check and Replace Worn Components

Over time, certain elements such as belts, blades, or filters may wear out or become damaged. It’s important to inspect these parts regularly and replace them if necessary. Regular checks can help catch potential issues early, preventing major breakdowns that might be costly or time-consuming to repair.

Keep the Equipment Clean

Maintaining cleanliness is crucial for the optimal performance of machinery. Dirt, grass, and debris can accumulate in various areas, leading to overheating or inefficient operation. Periodically cleaning the exterior, as well as clearing any blockages in the internal components, will ensure smooth functioning and reduce wear. Regular maintenance cleaning also prevents rust or corrosion that could shorten the equipment’s lifespan.