When it comes to maintaining and repairing your outdoor equipment, having a clear understanding of its individual elements is essential. This knowledge ensures that you can identify, replace, or fix any malfunctioning parts with ease. Whether you’re a hobbyist or a professional, an organized approach to the components can significantly improve efficiency during repairs.

Detailed illustrations and guides can be extremely helpful in understanding how each part fits into the overall design. By referencing these resources, you can avoid costly mistakes and ensure that your machine runs smoothly for a long time. Knowing the correct setup and order of assembly is crucial for effective repairs and maintenance.

Furthermore, understanding the typical problems that arise with specific parts can help you troubleshoot more effectively. Once you’re familiar with the layout and the function of each piece, it becomes easier to spot issues and act quickly, minimizing downtime and maximizing performance.

Understanding the Key Components

In order to maintain and repair your equipment, it’s crucial to have a solid understanding of its internal mechanisms. Every machine is built with multiple interconnected parts that work together to achieve its purpose. Knowing how these elements function individually and together can provide valuable insights when troubleshooting or upgrading the system.

Each component plays a specific role, from the engine to the smallest fasteners. When these parts wear out or become damaged, knowing the function of each piece allows for more precise replacements. This knowledge also helps prevent misidentification of problems, saving time and effort during maintenance tasks.

Familiarity with these essential components also enables better decision-making when it comes to repairs. By recognizing the specific responsibilities of each element, users can make informed choices about which parts need attention, improving overall performance and longevity of the equipment.

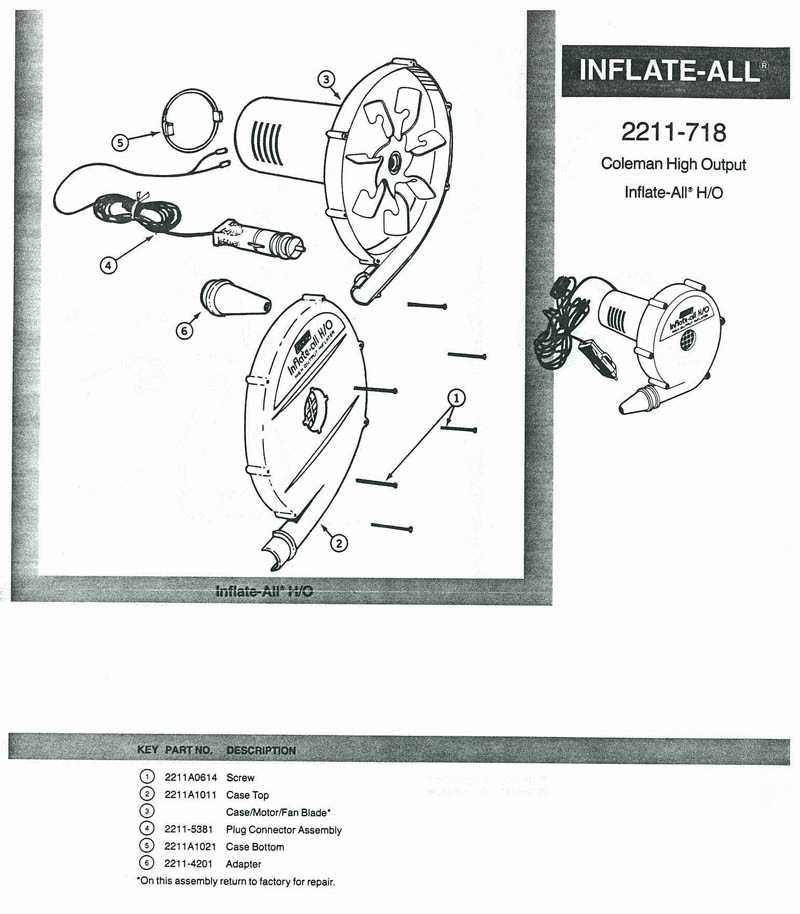

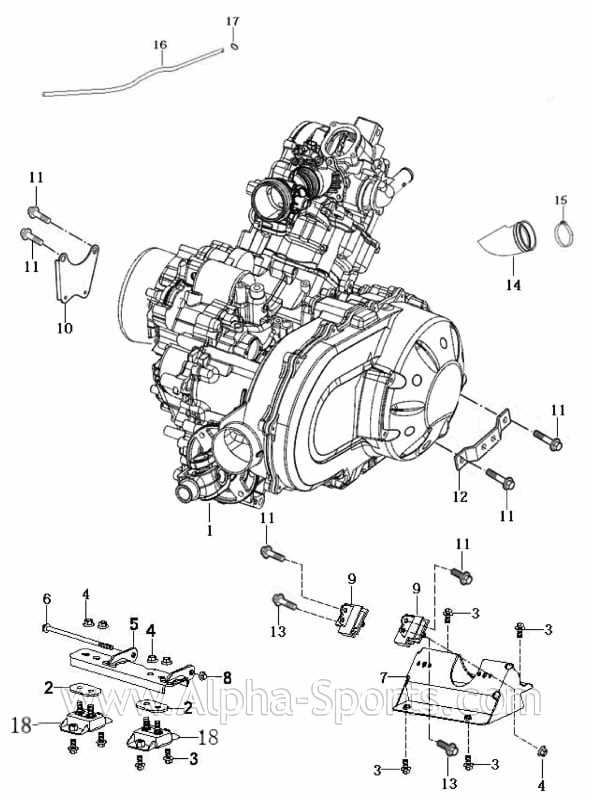

How to Use the Parts Illustration Effectively

Utilizing a visual representation of the components can greatly simplify the process of understanding the structure and assembly of your equipment. These resources serve as guides, providing clarity on how individual elements are arranged and connected. By referencing this illustration, users can gain insight into how the machine is built and identify areas that may require attention.

To make the most of these visuals, it’s important to first familiarize yourself with the key sections of the image. Focus on recognizing the major components and their placement within the system. Once you have a general understanding, you can pinpoint specific areas of interest more efficiently, whether it’s for routine checks or addressing specific issues.

Taking note of part numbers and their corresponding locations on the diagram is also crucial for finding exact replacements. This ensures that repairs or upgrades are done with the correct items, minimizing errors and improving the functionality of the equipment. By following the visual guide step-by-step, you can ensure a smooth and accurate assembly or repair process.

Common Issues and Repair Solutions

When working with mechanical equipment, certain issues are more likely to occur over time. Recognizing these problems early on and knowing how to address them can save both time and money. Whether it’s due to wear and tear or external factors, understanding the typical issues can help you avoid unnecessary repairs and extend the lifespan of your equipment.

Engine Performance Problems

One of the most common concerns is a decrease in engine performance. If the engine is sluggish or fails to start properly, it could indicate issues with fuel delivery, air intake, or ignition systems. Below are some common causes and solutions:

- Fuel clogging: Clean or replace the fuel filter to ensure smooth fuel flow.

- Ignition system failure: Inspect the spark plug and replace it if necessary.

- Air intake blockage: Check the air filter and clean or replace it if dirty.

Wear and Tear on Moving Parts

Another frequent issue arises from the wear and tear on moving components, which can cause noise, reduced efficiency, or complete failure. Regular maintenance is key to preventing further damage. Some solutions include:

- Lubrication: Apply the recommended lubricant to moving parts to reduce friction and wear.

- Part replacement: If certain components show significant damage, it may be necessary to replace them to avoid further complications.

- Alignment check: Ensure that all moving parts are aligned properly to avoid uneven wear.