When it comes to maintaining complex systems, having a clear understanding of their internal components is essential. Whether you’re troubleshooting issues or performing routine checks, recognizing each element’s function can simplify the process. A well-detailed schematic plays a key role in achieving this understanding.

Identifying each component within the system helps pinpoint potential problems and ensures that repairs are done accurately. Knowing how the various parts are interconnected allows for more efficient maintenance and prolongs the lifespan of the unit.

In this guide, we will explore how to interpret visual aids that depict the intricate structure of such systems. Understanding how to read these illustrations will empower you to handle any technical challenges confidently and with precision.

Understanding Internal System Layout

Grasping the arrangement of individual components within a system is fundamental to proper maintenance and troubleshooting. Knowing where each element is located and how it interacts with the others allows for efficient repairs and upgrades. This section will break down how to view and understand these layouts, ensuring you’re equipped with the knowledge to manage your unit effectively.

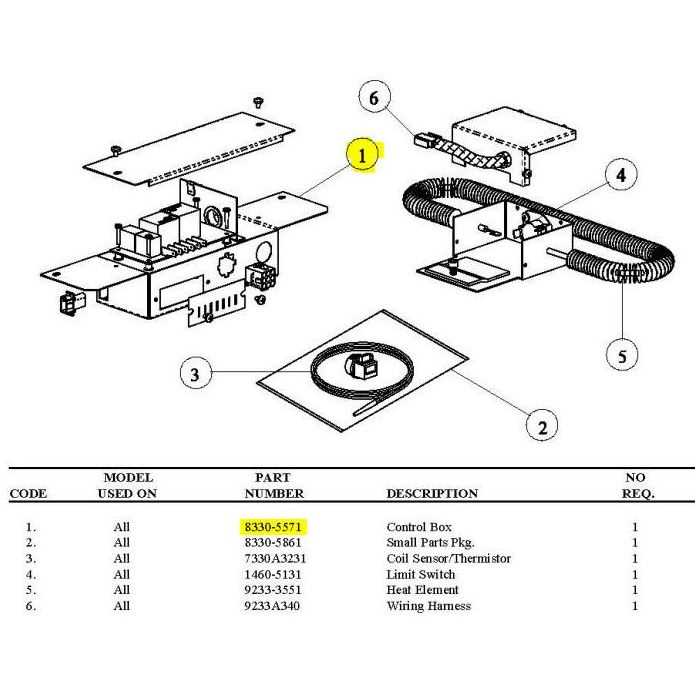

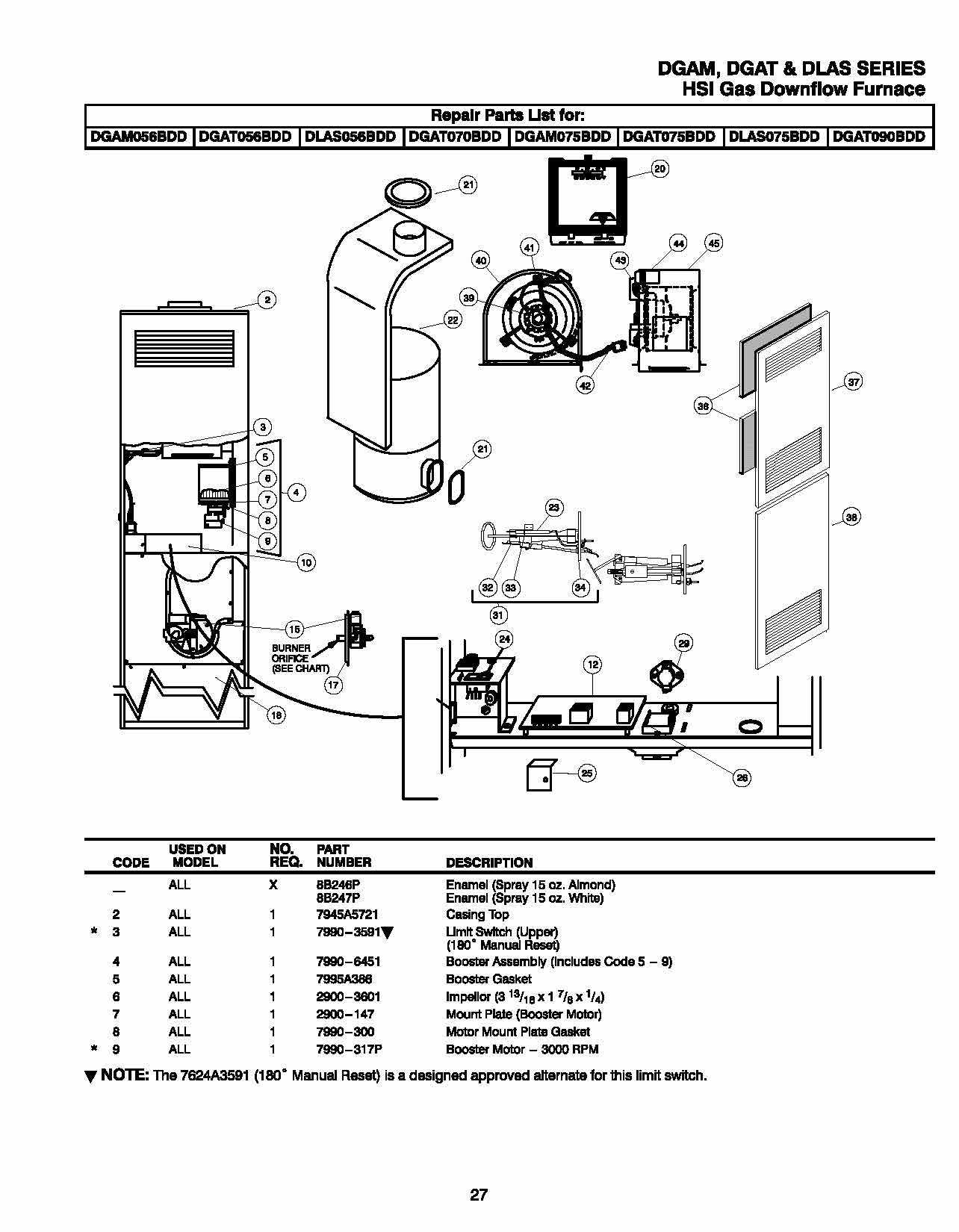

Interpreting the Visual Representation

Visual guides depicting the structure of a system typically highlight various components and their connections. By focusing on key sections, these illustrations simplify the process of identifying areas that need attention. Understanding these visuals will enable quicker and more accurate assessments of any issues.

Recognizing Critical Elements

Each component in a system serves a unique function, and recognizing these roles is essential. Some elements are central to the unit’s overall performance, while others support or regulate specific processes. Familiarity with the most critical components will help prioritize repairs or replacements and enhance overall system longevity.

Key Components of Coleman Mach Systems

Each system is made up of several critical elements that work together to ensure smooth operation. These core components are essential for the functionality and efficiency of the unit. Understanding what each piece does can help in troubleshooting and ensuring optimal performance.

Power and Control Systems

The power source and control mechanisms are at the heart of the system, providing energy and regulating operation. From electrical connections to thermostatic controls, these elements allow the user to manage the system’s behavior effectively.

Airflow and Ventilation Components

Ventilation plays a significant role in maintaining system efficiency. The air distribution parts ensure proper airflow, keeping the system running smoothly and maintaining the desired temperature. These components need to be well-maintained to avoid any disruptions in airflow, which could lead to performance issues.

How to Use the Parts Diagram Effectively

Understanding how to read and use visual representations of system components is essential for efficient maintenance and troubleshooting. These illustrations provide a detailed map of the unit’s inner workings, helping you identify parts that may need attention. Knowing how to navigate these visuals will save time and improve the accuracy of your repair or maintenance tasks.

Identify Key Sections First

Before diving into the details, focus on the primary sections of the illustration. Highlighting the most important components gives you a clear starting point. This approach allows for a more targeted examination of specific areas, minimizing the risk of overlooking crucial elements that could impact system performance.

Cross-Reference with Actual Components

Once you’ve located the main sections, compare them with the physical components in the unit. Cross-referencing the illustration with the actual layout ensures you’re looking at the right parts and helps confirm that the system is set up as intended. This method is particularly useful for verifying proper installation or identifying worn-out elements.