When working with mechanical equipment, understanding the internal structure and how various components interact is essential for efficient maintenance and troubleshooting. Familiarizing yourself with the layout of each part can significantly simplify the repair process, ensuring that you make informed decisions when addressing issues. This knowledge provides the foundation for both basic upkeep and advanced fixes.

In this section, we will explore the key elements of the system, identifying their specific roles and how they contribute to the overall function. By reviewing the detailed arrangement, users can gain valuable insights into how to approach repairs and keep everything running smoothly. Whether you’re a novice or an experienced technician, a clear understanding of the structure will guide you through each task with confidence.

Maintaining equipment longevity becomes easier once you know what to look for, and having a clear overview of the system’s parts allows for precise adjustments when necessary. This knowledge helps in optimizing performance and prevents unnecessary breakdowns, making the process more efficient and cost-effective.

Understanding Component Layout

To efficiently manage any mechanical system, it is essential to grasp the organization and interaction of its individual elements. Each component plays a vital role in ensuring that the equipment performs optimally. By familiarizing yourself with the configuration of these elements, you can enhance your ability to maintain and troubleshoot effectively, ensuring longevity and minimizing downtime.

Key Elements and Their Functions

Every machine has several key components, each designed for a specific task. These parts work together to achieve seamless operation, from power transmission to control mechanisms. Understanding the function of each element is crucial for identifying potential issues and addressing them promptly. A well-organized structure enables technicians and users to easily locate and assess parts for repair or replacement when necessary.

Layout and Configuration

The arrangement of the components is not arbitrary; it is carefully designed to optimize performance and ease of access. The layout ensures that each part can be maintained or replaced without disrupting the overall system. By analyzing the setup, you can anticipate how adjustments to one element might affect others, allowing for more efficient maintenance and repair strategies.

Exploring Key Parts and Their Functions

Each mechanical system is made up of various components that work in tandem to ensure smooth operation. Understanding the function of each element is vital for anyone involved in maintenance or troubleshooting. By identifying the role of key components, users can more easily detect potential problems and perform necessary repairs or adjustments.

Power transmission elements, such as the engine or motor, are responsible for converting energy into mechanical movement. These parts are at the core of the system’s functionality, driving the entire operation. Similarly, control mechanisms like switches or regulators ensure that the system runs efficiently by managing the flow of power and adjusting settings based on demand.

Structural components, including frames or housings, provide support and protection to the inner workings. These elements are essential for maintaining the integrity of the system over time. Understanding how each part contributes to the overall function of the equipment allows for more effective management, prolonging its lifespan and improving its performance.

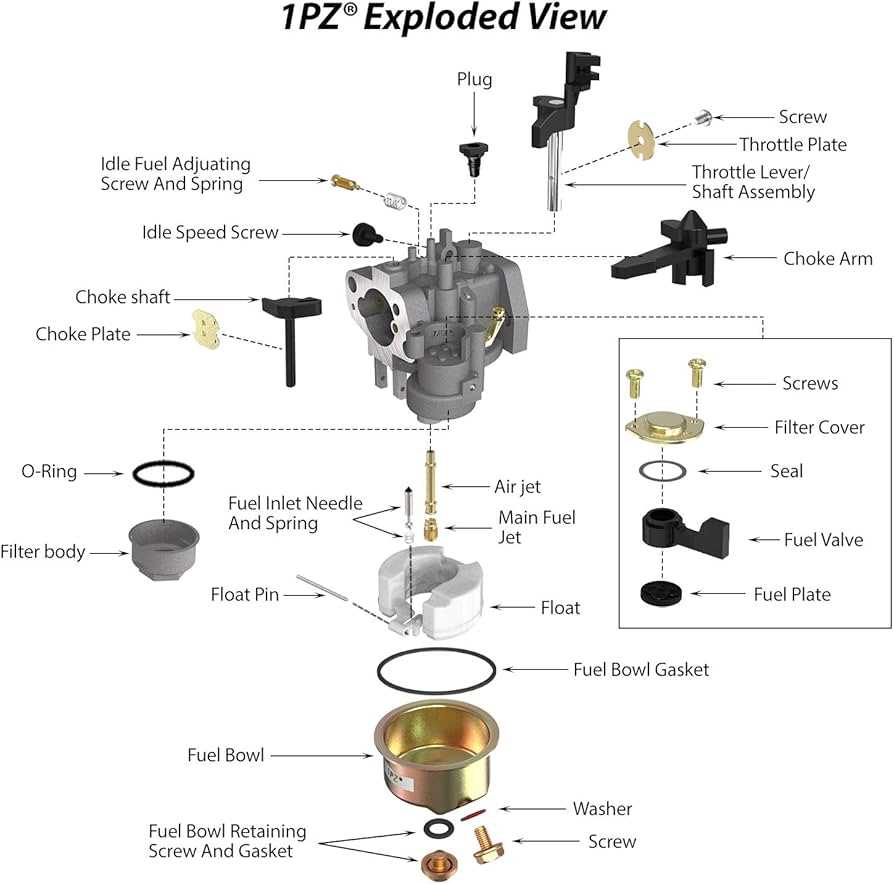

How to Read the Parts Layout

Understanding the layout of mechanical components is crucial for efficient maintenance and repairs. Visual representations of the system help users identify each element, allowing them to determine its role and location within the structure. By mastering how to interpret these layouts, you can quickly assess the condition of components and make informed decisions about their care or replacement.

Breaking Down the Visual Representation

The layout typically provides a clear view of the equipment’s structure, with each element numbered or labeled for easy identification. Key symbols are used to represent different types of components, such as switches, motors, or structural supports. By learning the meaning of these symbols, users can quickly locate specific parts and understand their functions within the system.

Using the Layout for Troubleshooting

Once familiar with the layout, it becomes a powerful tool for troubleshooting. Identifying which component may be malfunctioning or in need of replacement becomes much easier when you can cross-reference the visual representation with the actual physical setup. This knowledge not only saves time but also ensures that repairs are made efficiently and accurately.

Step-by-Step Guide for Users

Understanding how to navigate and interact with your system’s internal structure is key to successful operation and maintenance. By following a systematic approach, users can efficiently identify, troubleshoot, and replace components as needed. This guide will provide you with a clear, step-by-step process to ensure you’re confident in managing the system’s components.

Identifying Key Components

The first step is to familiarize yourself with the essential elements of the system. Review the layout or visual representation to understand the placement and function of each part. Once you know where each component is located, it becomes easier to spot potential issues or areas that may need attention.

Performing Maintenance and Adjustments

Once the components are identified, performing regular checks is important for ensuring smooth operation. Follow the steps outlined in the user manual or layout to make adjustments or replace malfunctioning parts. With this methodical approach, you can ensure that the system continues to function at its best, extending its lifespan and improving its performance.

Tips for Efficient Maintenance and Repairs

Proper upkeep and timely repairs are crucial for maintaining the efficiency and longevity of any mechanical system. By adopting a proactive approach, users can prevent costly issues and ensure smooth operation. The following tips provide a practical framework for effective maintenance and repair, helping to identify problems early and resolve them swiftly.

Regular Inspection and Cleaning

One of the most effective ways to keep equipment in top condition is through routine checks and cleaning. This helps to identify wear and tear before it leads to significant problems. Regular cleaning also prevents the buildup of debris that can interfere with system performance. Consider the following practices:

- Inspect all components for signs of wear or damage.

- Clean dust, dirt, and debris from critical parts to maintain proper functioning.

- Check for loose connections or fasteners and tighten them as needed.

Efficient Repair Process

When repairs are needed, it’s important to follow a systematic approach to ensure accuracy and prevent future issues. Here are key steps to make the repair process more efficient:

- Consult the system’s manual or layout to locate the affected component.

- Ensure you have the proper tools and replacement parts before beginning the repair.

- Take note of any troubleshooting steps to help identify the root cause of the issue.

- Test the system thoroughly after the repair to confirm proper functionality.

By following these guidelines, you can minimize downtime and maintain optimal performance for an extended period.