Proper maintenance and efficient operation of agricultural equipment depend on understanding the intricate details of its structure. Whether for occasional use or regular tasks, knowing how to identify and troubleshoot individual components can make a significant difference in the performance and longevity of your machinery.

Accurate knowledge of each element is essential for anyone looking to ensure optimal functionality. This includes recognizing how parts work together to achieve the desired results. A thorough grasp of the system is key to addressing potential issues before they become significant problems.

By reviewing the overall setup and gaining insight into each individual piece, you can improve both the maintenance process and the efficiency of your equipment. This article will guide you through the most critical aspects of your machinery, highlighting important features and providing advice on care and troubleshooting techniques.

Understanding Equipment Components

To ensure the effective operation of your agricultural machinery, it is crucial to have a deep understanding of the various elements that make up the system. Each individual component plays a specific role, and recognizing their functions will allow you to maintain and troubleshoot your equipment more efficiently. In this section, we will explore the key features that you should familiarize yourself with for optimal performance.

Key Features and Functions

Every piece of equipment consists of several critical elements that work in unison to achieve the desired results. For example, pumps, nozzles, and valves each have a unique role in the system. The pump facilitates the flow of liquid, while the nozzles control its distribution. Valves regulate the pressure, ensuring that the system operates smoothly. Understanding how each of these components interacts will help you address issues quickly and perform necessary repairs when needed.

Common Troubleshooting Areas

Familiarizing yourself with the common problem areas of your equipment can prevent costly repairs and downtime. Leaks, clogging, and pressure inconsistencies are among the most frequent issues that arise in similar systems. Regular inspection of hoses, connectors, and seals ensures that there are no blockages or signs of wear that might affect performance. Knowing where to look and what to check will enable you to catch minor issues before they escalate into major problems.

How to Identify Key Components

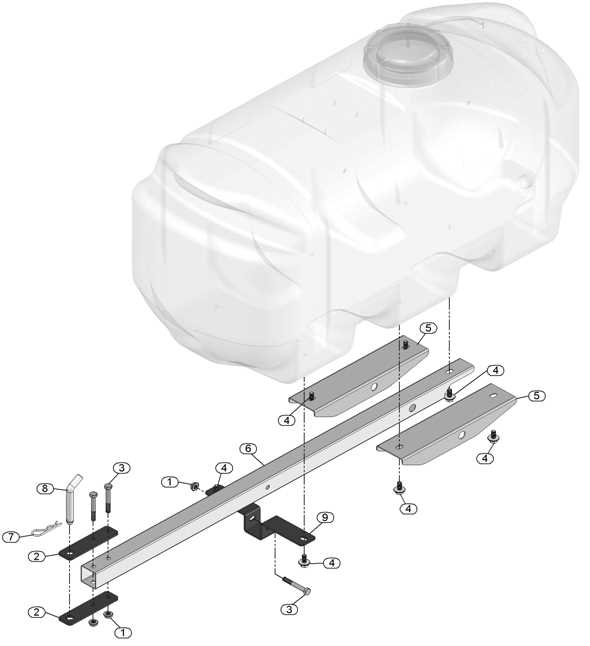

Recognizing the essential elements of your equipment is crucial for efficient maintenance and troubleshooting. Each part plays a vital role, and understanding how to identify them allows for quicker repairs and better performance. This section will guide you through the process of identifying the most important components and their functions, ensuring you know exactly where to focus your attention.

Common Components and Their Functions

To help identify and understand the various components, we’ve outlined the most common ones found in similar systems. Familiarity with their location and purpose will assist in both diagnostics and regular maintenance.

| Component | Function |

|---|---|

| Pump | Transfers liquid through the system, ensuring pressure is maintained for efficient operation. |

| Nozzles | Control the distribution of the liquid, ensuring even coverage during use. |

| Valves | Regulate the flow and pressure of the liquid, preventing overflows or underperformance. |

| Hoses | Carry liquid from the source to the applicator, connecting various components. |

| Connectors | Ensure a secure connection between hoses, nozzles, and other components to avoid leaks. |

By understanding the function of each of these components, you can easily spot potential issues and perform necessary repairs or replacements. Regular inspection of these key areas ensures optimal operation and extends the life of your equipment.

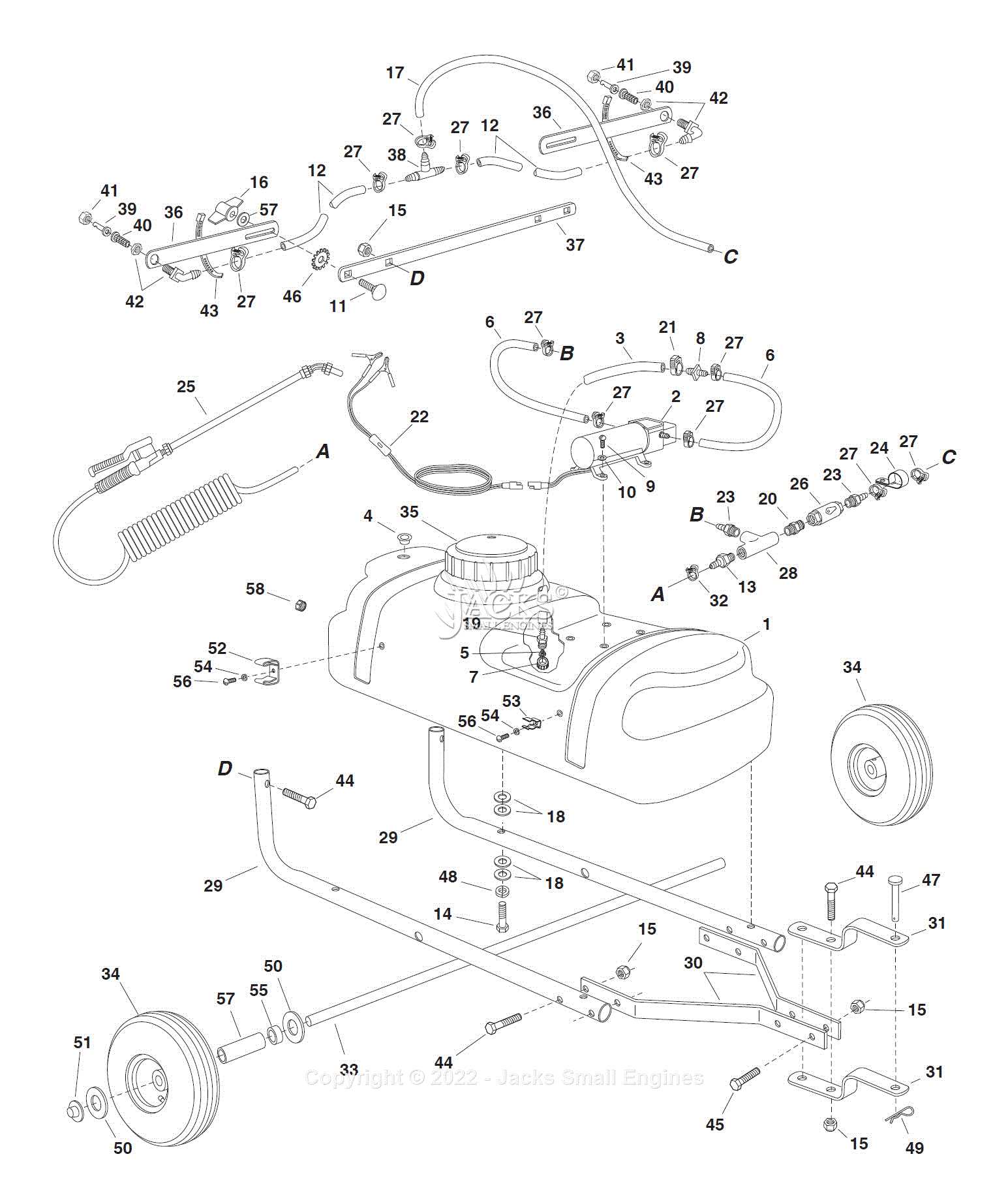

Step-by-Step Diagram Explanation

Understanding the structure of your equipment is essential for proper maintenance and troubleshooting. A clear, step-by-step guide helps break down each component, making it easier to locate and address any issues. This section provides a comprehensive breakdown of the system, walking you through the key elements and their interactions to ensure smooth functionality.

Breaking Down the Assembly

The assembly process involves several interconnected parts that must be understood individually before putting everything together. The pump, nozzles, and connectors must be correctly installed and aligned to achieve optimal performance. This step-by-step approach guides you through the assembly process, ensuring that each piece is placed in the right location.

Understanding the Flow of Liquid

Once the components are correctly assembled, it is important to understand how liquid flows through the system. Each part plays a crucial role in ensuring the even distribution of the substance. Knowing how to read the flow can help identify any blockages or issues that might arise, allowing for quick fixes without interrupting operations.

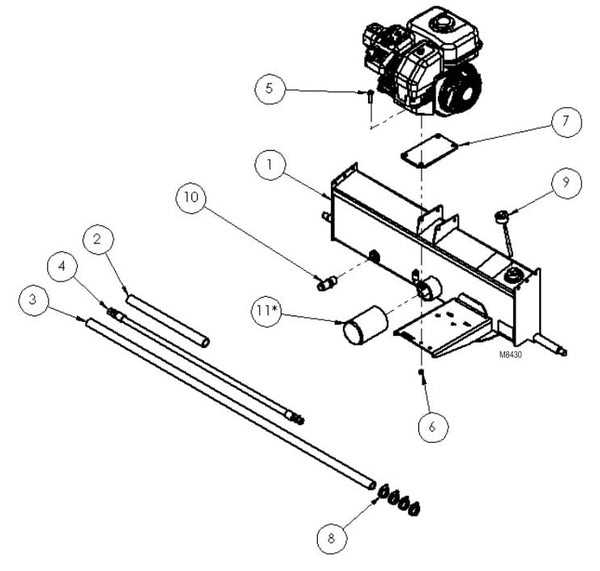

Assembly and Function of Each Part

Each element of your equipment is designed to perform a specific task that contributes to the overall efficiency and effectiveness of the system. Understanding the assembly process and the function of each component ensures proper installation and operation. In this section, we will explore the role of each part and how they work together to achieve optimal results.

Pumps and Valves

The pump is responsible for moving liquid throughout the system, creating the necessary pressure for distribution. The valves regulate this flow, ensuring the correct pressure is maintained and preventing leaks or overflows. Together, these components enable the system to function smoothly by controlling the flow and pressure of the liquid.

Nozzles and Hoses

Nozzles are crucial for controlling the distribution of liquid. They ensure even application by adjusting the spray pattern and amount released. Hoses connect the various components, allowing liquid to flow from one part to another. Properly installed hoses and functioning nozzles are key to efficient performance and avoiding clogs or uneven application.

Maintenance Tips for Longevity

Proper care and regular maintenance are essential for extending the life of your equipment. By following a few simple guidelines, you can ensure that your system operates efficiently for years. This section will provide helpful tips to maintain each component and prevent unnecessary wear and tear.

Regular Inspections

Frequent checks of the key elements can help catch minor issues before they turn into major problems. Inspecting parts such as hoses, connectors, and nozzles will help identify wear and tear early on. Consider the following:

- Inspect hoses for signs of cracks or leaks.

- Check nozzles for clogs or uneven spray patterns.

- Look for loose connections that could lead to fluid loss.

Cleaning and Lubrication

Cleaning your equipment after each use and applying lubrication where needed will ensure smooth operation and prevent rust or corrosion. Follow these steps:

- Rinse all components thoroughly to remove any residue or buildup.

- Apply lubricant to moving parts, such as pumps and valves, to reduce friction.

- Store the equipment in a dry place to avoid exposure to moisture.

By following these simple steps, you can significantly improve the lifespan of your machinery and maintain its peak performance.