When working with material handling equipment, it’s crucial to have a clear understanding of its individual components. Each element plays a key role in the overall functionality, ensuring safe and efficient operation. Knowing how each part works can significantly improve the maintenance process and help prevent costly breakdowns.

Proper knowledge of the machinery’s layout allows operators and technicians to identify issues early and perform necessary repairs or replacements. This helps in extending the lifespan of the equipment while minimizing downtime.

Regular inspections and awareness of potential wear and tear can guide you in making informed decisions regarding upkeep. A well-maintained system is not only safer but also more reliable for everyday tasks.

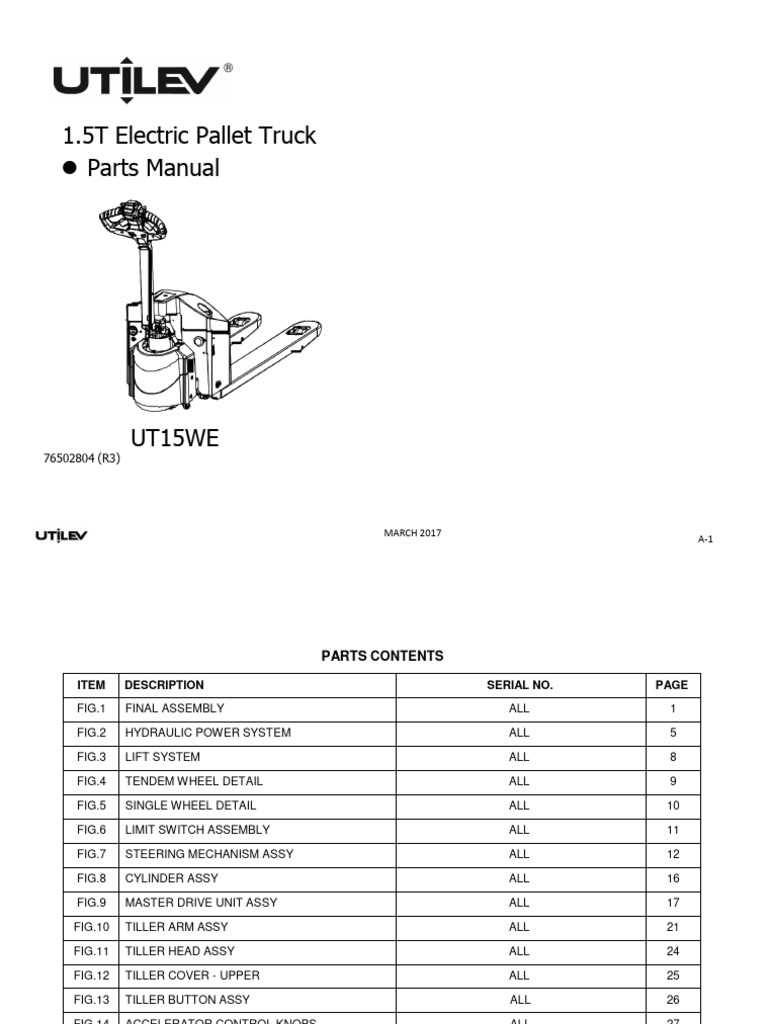

Understanding Equipment Components

Every piece of machinery consists of various interconnected elements that work together to achieve optimal performance. From the smallest screws to larger mechanical systems, understanding how these components interact is essential for smooth operations. Familiarity with each part helps in identifying potential issues and performing timely maintenance to prevent system failures.

The functionality of the equipment heavily depends on the precise coordination of its different parts. Each component serves a specific purpose, whether it’s for mobility, stability, or control. Proper care and attention to detail in maintaining these elements ensure that the equipment functions efficiently and remains durable over time.

Critical components, such as the lifting mechanism, wheels, and handle systems, are fundamental to its usability. A breakdown in any of these systems can result in significant operational delays. Regular checks on each part’s condition can help detect signs of wear before they lead to failure, reducing costly repairs and downtime.

Common Issues with Equipment Components

Like any mechanical device, material handling equipment can experience various issues over time due to wear, improper use, or lack of maintenance. Understanding these common problems is essential for identifying potential failures before they disrupt operations. Recognizing the symptoms of malfunction can help operators and technicians take corrective actions quickly, avoiding costly repairs and downtime.

Hydraulic and Lifting Mechanism Failures

One of the most frequent issues involves the hydraulic system, which is responsible for lifting and lowering loads. Leaks or low fluid levels can cause the equipment to lose lifting power, leading to inefficiency and difficulty in handling heavy loads. Regular inspection of the hydraulic pump and seals can prevent such issues and extend the life of the system.

Wheel and Steering Problems

Another common issue arises with the wheels and steering mechanism. Over time, wheels can become worn out, making the equipment harder to maneuver. Additionally, debris or damage to the steering system can cause stiffness or difficulty in turning. Keeping wheels clean and inspecting the steering components regularly helps maintain smooth movement and ensures safe operation.

How to Maintain Your Equipment

Proper maintenance is key to ensuring the longevity and reliability of any machinery. Regular care not only enhances performance but also reduces the likelihood of unexpected breakdowns. By following a structured maintenance routine, you can ensure that the equipment remains functional, safe, and efficient throughout its lifespan.

Routine Inspections are essential for detecting wear and tear on critical components such as the hydraulic system, wheels, and steering mechanisms. Regular checks can identify issues before they become major problems, allowing for timely repairs and preventing costly downtime.

Lubrication and Cleaning are two important aspects of upkeep. Keeping moving parts properly lubricated minimizes friction and wear, while cleaning helps prevent debris from accumulating and damaging components. Properly maintaining these areas will keep the equipment running smoothly and ensure a longer service life.