When it comes to keeping your material handling equipment in top condition, having a clear overview of its structure is essential. A detailed reference can help identify individual components, ensuring proper upkeep and minimizing downtime. This guide provides an in-depth look at the critical elements that make up your equipment and their functions.

Proper knowledge of the equipment’s construction allows users to perform repairs more efficiently. Whether it’s for replacing worn-out parts or troubleshooting issues, understanding the layout and role of each component can save both time and money. In this article, we explore the key features that should be considered when maintaining your device.

By following a structured approach to repair, operators can extend the lifespan of their machinery and ensure smooth operation for years to come. Accurate identification and usage of the reference guide will be an invaluable asset for anyone working with these types of vehicles.

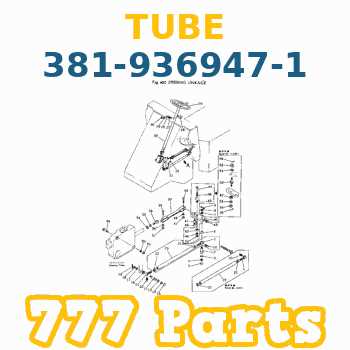

Understanding the Pallet Truck Component Layout

To effectively manage maintenance and repairs, it’s crucial to have a clear understanding of the internal structure of your handling equipment. This overview provides insights into how each element is connected and functions together, ensuring smooth operation. By becoming familiar with the design, users can more easily pinpoint areas that require attention or replacement.

Identifying Essential Elements

The primary components of any material handling machine are crucial for its performance and reliability. These elements include mechanical, electrical, and hydraulic systems, each working in tandem to ensure the equipment functions as intended. Knowing their locations and functions within the system simplifies the process of troubleshooting and servicing.

How to Utilize the Reference for Repairs

Having access to a well-organized layout is vital when conducting repairs. It not only helps in identifying specific parts but also assists in understanding how they interact with other components. With a comprehensive map of the machinery, operators can more efficiently replace damaged items or make necessary adjustments to restore optimal functionality.

Key Components of the Pallet Truck

A material handling vehicle consists of several essential elements that work together to ensure efficiency and reliability. These components are designed to provide optimal performance, durability, and ease of operation. Understanding these key parts is vital for both maintenance and troubleshooting, as it helps operators address issues quickly and accurately.

Hydraulic System

The hydraulic system is one of the most important features of the machine. It controls the lifting mechanism, enabling the truck to raise and lower loads smoothly. Proper maintenance of the hydraulic components ensures safe and efficient operation, preventing issues such as leaks or reduced lifting capacity.

Wheels and Steering Mechanism

The wheels and steering mechanism provide maneuverability and stability, allowing the truck to navigate tight spaces and transport heavy loads with ease. Regular inspection of these components is essential to prevent wear and ensure smooth movement across various surfaces.

How to Use the Reference for Repairs

When it comes to fixing and maintaining your equipment, having a detailed reference guide is crucial. This tool allows you to identify specific elements, understand their functions, and locate any issues that may arise. By following a clear schematic, you can quickly determine which parts need attention, making repairs more efficient and reducing downtime.

Step-by-Step Approach

The first step in using the reference for repairs is to locate the part you need to inspect or replace. Each section of the equipment is typically broken down into individual components, making it easier to pinpoint the specific issue. Once you’ve identified the faulty part, you can proceed with troubleshooting or replacement based on its function and location.

Tips for Efficient Repair

It’s essential to familiarize yourself with the entire layout before beginning repairs. Understanding how different parts are connected and interact can help avoid mistakes and streamline the repair process. Additionally, keeping the reference nearby during the work allows for quick verification and ensures that each step is followed correctly.