When it comes to maintaining and repairing lawn care machinery, understanding the components that make up the system is essential. Properly identifying and assembling the different parts ensures the equipment operates smoothly and lasts longer. Having a clear breakdown of each individual element can greatly simplify troubleshooting and repairs.

With a detailed reference, users can gain a better understanding of how various pieces fit together and function. This knowledge helps in identifying wear and tear, preventing further damage, and optimizing the machine’s performance. Whether you are replacing a worn part or simply performing routine maintenance, knowing the key elements of the system will save time and effort.

Efficient maintenance becomes possible when you have a solid understanding of the individual components. With the right information, managing and enhancing the functionality of your lawn equipment is no longer a complicated task.

Understanding Lawn Equipment Components

Each lawn care machine consists of various individual elements that work together to achieve optimal performance. Understanding these key components is crucial for effective maintenance and repairs. The system relies on a series of interconnected pieces, each playing a specific role in the machine’s operation. Familiarity with the functions of each part ensures smooth operation and helps users identify issues early on.

From the engine to the collection system, each component has its function, whether it is responsible for power delivery, cutting, or waste management. Knowing how these elements interact allows for efficient problem-solving when issues arise. Regular inspection and proper handling of these components will extend the lifespan of the equipment and reduce the likelihood of major malfunctions.

By recognizing the main parts and understanding their purpose, you can make informed decisions about maintenance and repairs. A detailed look at the system’s structure reveals the importance of each individual piece, ensuring that everything functions harmoniously. This knowledge is the foundation for keeping your equipment running at peak efficiency.

How to Read a Lawn Equipment Assembly Breakdown

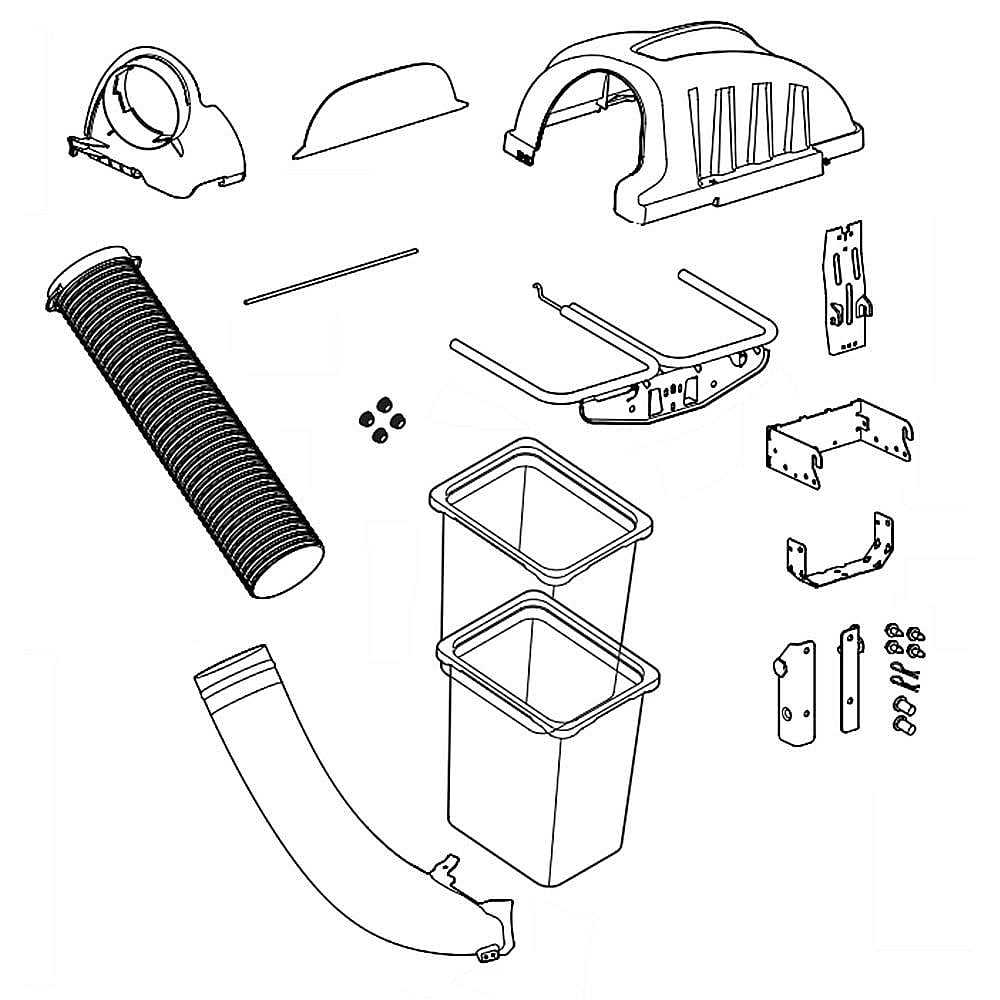

Understanding a machine’s assembly chart is crucial for effective repairs and maintenance. These visual guides help users identify each individual component, showing how they connect and function within the larger system. By interpreting the layout correctly, users can pinpoint issues and make informed decisions about replacements or repairs.

Begin by familiarizing yourself with the overall structure. Typically, these breakdowns are divided into sections that correspond to different areas of the machine, such as the engine, collection system, and chassis. Each part is labeled with a reference number or code, allowing you to easily match it with the corresponding item in a parts list.

Look for any symbols or notations that indicate specific details, such as size, shape, or the direction in which the component should be installed. Pay attention to the relationships between parts–how they fit together and interact. This will give you a clearer understanding of the machine’s mechanics and guide you through proper assembly or disassembly.

Common Lawn Equipment Repairs

Routine use of lawn care machines often leads to wear and tear, requiring regular repairs to maintain performance. Many of these issues are straightforward and can be fixed with a basic understanding of the machine’s components. Recognizing common problems early allows for quicker and more cost-effective repairs, ensuring that the equipment remains functional for years to come.

Common Issues and Solutions

- Clogged Collection System: A clogged chute or collection bag is a frequent problem. Clear any blockages by checking for debris buildup and cleaning the affected areas thoroughly.

- Worn-out Belts: If the belts are slipping or not working properly, they may need to be replaced. Inspect them regularly for signs of fraying or stretching.

- Loose or Damaged Screws: Over time, screws and bolts can become loose or damaged. Tighten or replace them as necessary to prevent further issues.

- Faulty Motor or Engine: If the engine is not starting, it may be due to fuel or spark plug issues. Ensure the fuel system is clean and the spark plugs are in good condition.

Preventive Measures

- Regularly clean all parts to prevent buildup and keep them in optimal condition.

- Perform periodic inspections of belts and connections to avoid unexpected failures.

- Follow the manufacturer’s maintenance schedule for oil changes and other essential upkeep tasks.