Understanding the Cub Cadet LT1045 Components

Every mechanical machine is made up of intricate elements that work in harmony to ensure smooth functionality. For an outdoor vehicle designed for both utility and efficiency, understanding these individual units is essential for both maintenance and repair. When analyzing these components, it’s important to recognize how each part contributes to the overall performance and longevity of the equipment.

Engine plays a vital role in powering the entire system. Its components, including the carburetor, air filter, and spark plug, ensure proper combustion and smooth operation. The transmission is equally crucial, as it regulates the movement of the vehicle, allowing for precise speed control and the transfer of power to the wheels.

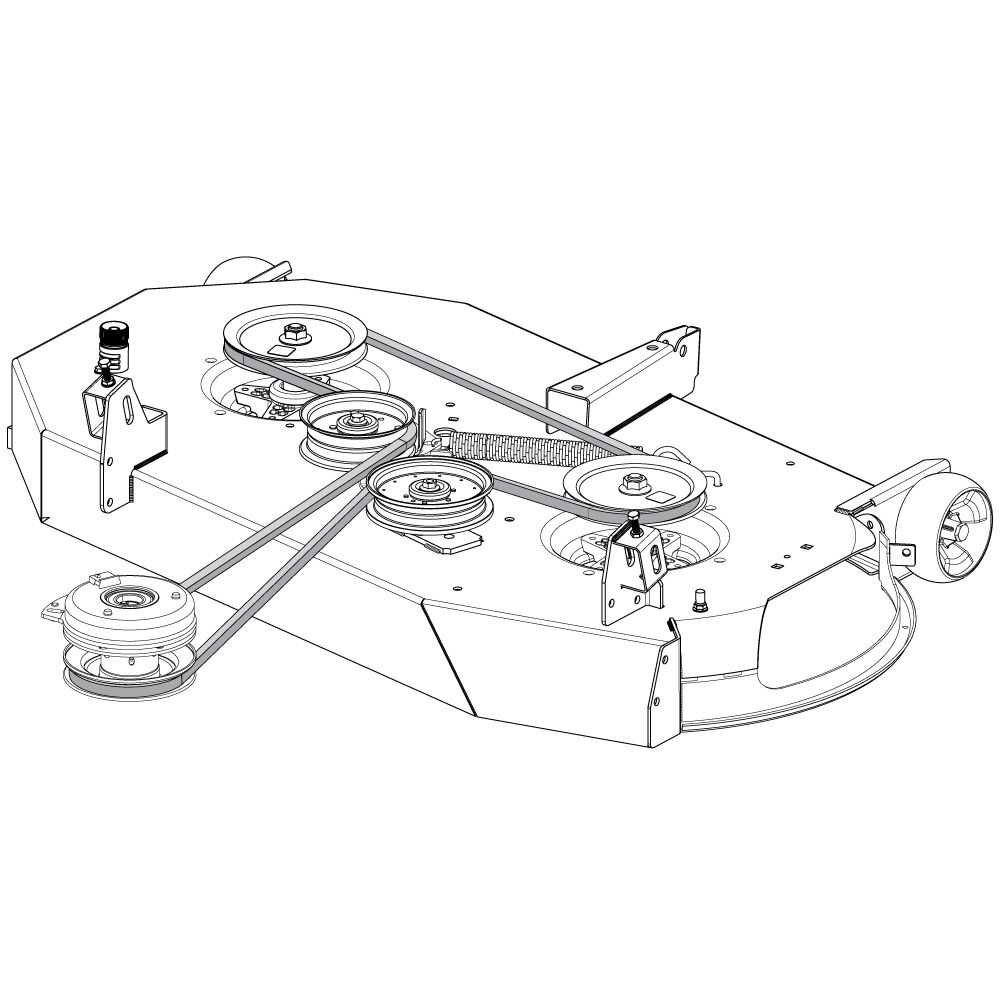

Next, the steering mechanism and wheel assembly provide the operator with control, facilitating maneuverability over different terrains. The deck, responsible for cutting, operates with sharp blades that interact with the engine’s power to create an even cut. Regular inspection of these and other small but important components, such as belts and pulleys, ensures long-term efficiency.

Finally, understanding how each unit interacts within the system provides a deeper insight into the mechanics. Regular servicing, from changing the oil to replacing worn-out parts, can significantly extend the life of the machinery, helping to maintain its performance for years to come.

Common Repairs Using the LT1045 Diagram

Understanding the layout and function of key components in any machinery can greatly simplify the repair process. With the right guide, common issues can be easily identified, and replacement or maintenance tasks become more manageable. By referring to a detailed visual representation, users can troubleshoot and address mechanical failures efficiently, ensuring their equipment operates smoothly again.

One common issue often encountered is a malfunctioning engine. Problems with starting or poor performance are typically related to the spark plug, air filter, or fuel lines. Using the schematic, it’s easy to locate these parts and replace or clean them as needed. Another frequent repair involves the cutting deck, where dull or damaged blades may need sharpening or replacing. Accessing the deck components using a clear guide can simplify this task and restore the mowing efficiency.

The transmission system can also face issues, such as slippage or difficulty changing gears. The diagram allows users to pinpoint the exact areas where wear and tear may have occurred, such as the belts or pulleys, enabling quick fixes to restore proper function. Regular checks and minor repairs to these essential parts help maintain the vehicle’s overall performance.

How to Read the LT1045 Parts Diagram

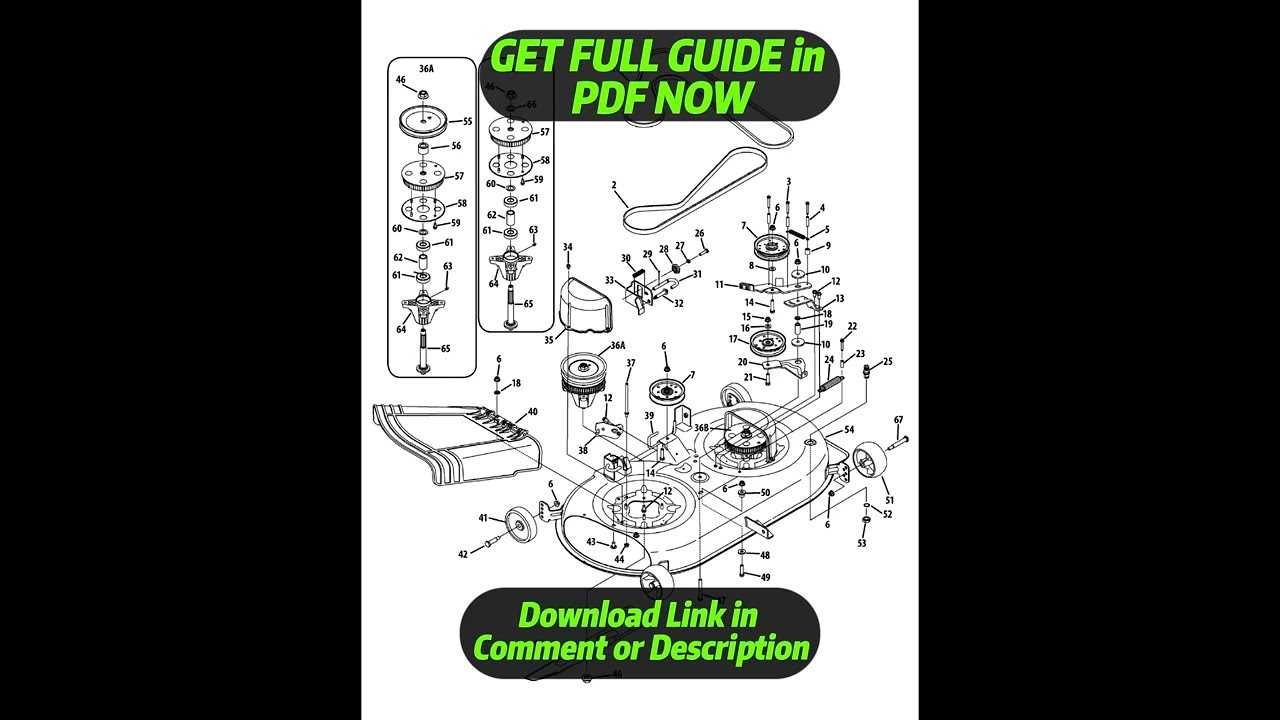

Understanding how to read a visual representation of a machine’s components is crucial for effective maintenance and repair. These illustrations serve as detailed guides, showing how individual parts fit together and function within the larger system. Knowing how to interpret these schematics can significantly improve your ability to locate issues and perform repairs accurately.

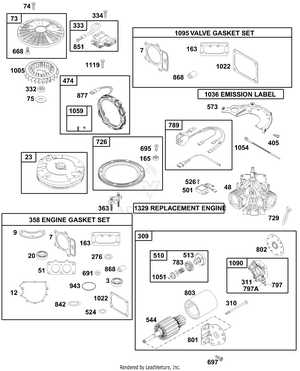

Identifying Components

The first step in reading such a schematic is to familiarize yourself with the symbols used for different components. Each part will be represented by a unique figure or number, often accompanied by labels for easy identification. Take note of the corresponding reference numbers, as they link to a parts list that provides further details about each item, such as its name, specifications, and compatibility.

Following the Connections

Once you’ve identified the key parts, it’s important to understand how they are interconnected. The lines and arrows on the diagram show how parts interact with one another, such as how the engine connects to the transmission or how the steering mechanism engages with the wheels. By following these connections, you can pinpoint potential trouble areas or ensure correct assembly when performing repairs or upgrades.