Maintaining your lawn equipment is crucial for ensuring it runs smoothly and efficiently for years. Understanding how each component functions together can make repairs and maintenance tasks much easier. With proper guidance, you can easily identify which parts need attention and how to replace them effectively.

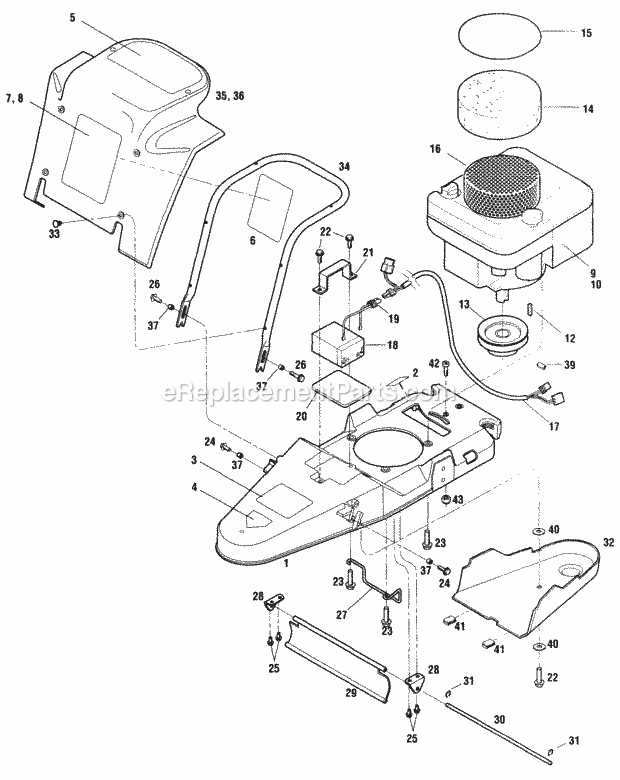

Detailed illustrations can assist in recognizing specific components, helping users make informed decisions during repair or replacement processes. These resources offer a clear visual understanding of the structure, enabling a quick and accurate fix without unnecessary confusion.

With a little knowledge of the equipment’s internal workings, you can tackle common issues that arise during use. Whether it’s replacing worn-out elements or ensuring proper installation of new parts, having the right information at hand can save both time and money in the long run.

Understanding the Cub Cadet ST 100 Parts

To maintain your lawn care equipment efficiently, it’s essential to have a clear understanding of how each individual component contributes to its overall function. Each element of the machine plays a specific role in ensuring proper operation, from the engine to the smaller auxiliary pieces. Familiarizing yourself with these components allows for more precise identification of issues and quicker repairs when needed.

Key components such as the drive system, engine, and cutting mechanism work in harmony to provide optimal performance. Knowing the exact placement and function of these elements can help prevent unnecessary replacements and ensure that your equipment continues to operate at its best.

Additionally, having a visual representation of the different parts can be incredibly useful. These resources help break down complex systems into manageable pieces, allowing for a better understanding of how everything fits together. When you know how the machine is assembled, it’s easier to spot problems and take action before they cause significant damage.

How to Use the Parts Diagram Effectively

Utilizing a visual reference for equipment maintenance is an invaluable tool. It helps simplify complex assemblies by breaking them down into clear, identifiable components. When used properly, these resources can drastically improve your repair process by providing a comprehensive overview of the machine’s structure.

Step-by-Step Approach

Begin by carefully reviewing the entire schematic, taking note of each labeled component. Understand the function of each part and how it connects to other elements. This way, you’ll be able to locate the exact part that may need attention, whether it’s worn out or malfunctioning.

Ensure Accuracy in Identification

Pay close attention to any detailed markings or numbers next to each part. These identifiers are crucial for sourcing replacements. Cross-checking part numbers with your equipment’s manual or trusted suppliers ensures that you select the correct pieces, preventing mistakes and unnecessary delays in repairs.

Common Issues and Solutions for ST 100

Like all machinery, lawn equipment is prone to certain malfunctions over time. Identifying common problems and addressing them quickly can help extend the lifespan of your machine. From engine trouble to issues with the drive system, knowing what to look for allows you to act before a minor issue becomes a major repair.

Engine Starting Problems

One frequent issue that many users face is difficulty starting the engine. This could be due to several factors, such as a clogged fuel filter, old fuel, or a weak battery. To resolve this, start by checking the fuel system for any blockages or stale fuel. Replace the fuel filter if necessary and ensure the battery is fully charged to give the engine the power it needs to start smoothly.

Drive System Malfunctions

If the machine isn’t moving properly or struggles to engage, the issue may lie with the drive system. Common causes include worn-out belts or misaligned components. Inspect the drive components carefully and replace any damaged parts to restore the system’s functionality. Regular maintenance and tightening of belts can prevent these problems from occurring frequently.