When it comes to maintaining and repairing a classic air rifle, having a clear understanding of its individual components is essential. Knowing how each part interacts with the others helps you identify potential issues, replace worn-out pieces, and ensure smooth operation for years to come.

Every air gun is composed of various elements that serve specific functions. Recognizing these pieces and learning how to navigate their assembly allows users to troubleshoot problems effectively. Whether you’re aiming to perform routine maintenance or tackle a more complex fix, familiarity with the overall construction is key.

By referring to an accurate guide of these essential parts, you can approach repairs with confidence. Proper knowledge of how these components are structured and how they fit together will save time and prevent unnecessary mistakes, making your repair process much more efficient.

Understanding Daisy Red Ryder Components

Each air rifle consists of several key elements that work together to ensure proper functionality. From the main body to the smallest internal springs, every component plays a crucial role in the performance and longevity of the gun. Understanding these individual pieces is important for both routine maintenance and troubleshooting.

At the heart of the assembly is the mechanism that drives the propulsion of the projectile. Surrounding this core, various structural components, like the stock and barrel, provide stability and accuracy. These external parts protect the inner workings while enhancing the user’s experience.

The internal components, such as the trigger assembly and cocking system, are where most of the maintenance attention is needed. Knowing how these parts interact ensures that users can perform necessary repairs without causing further damage to the rifle. A thorough understanding of these pieces also prevents common issues like misfires or reduced power.

How to Read a Parts Diagram

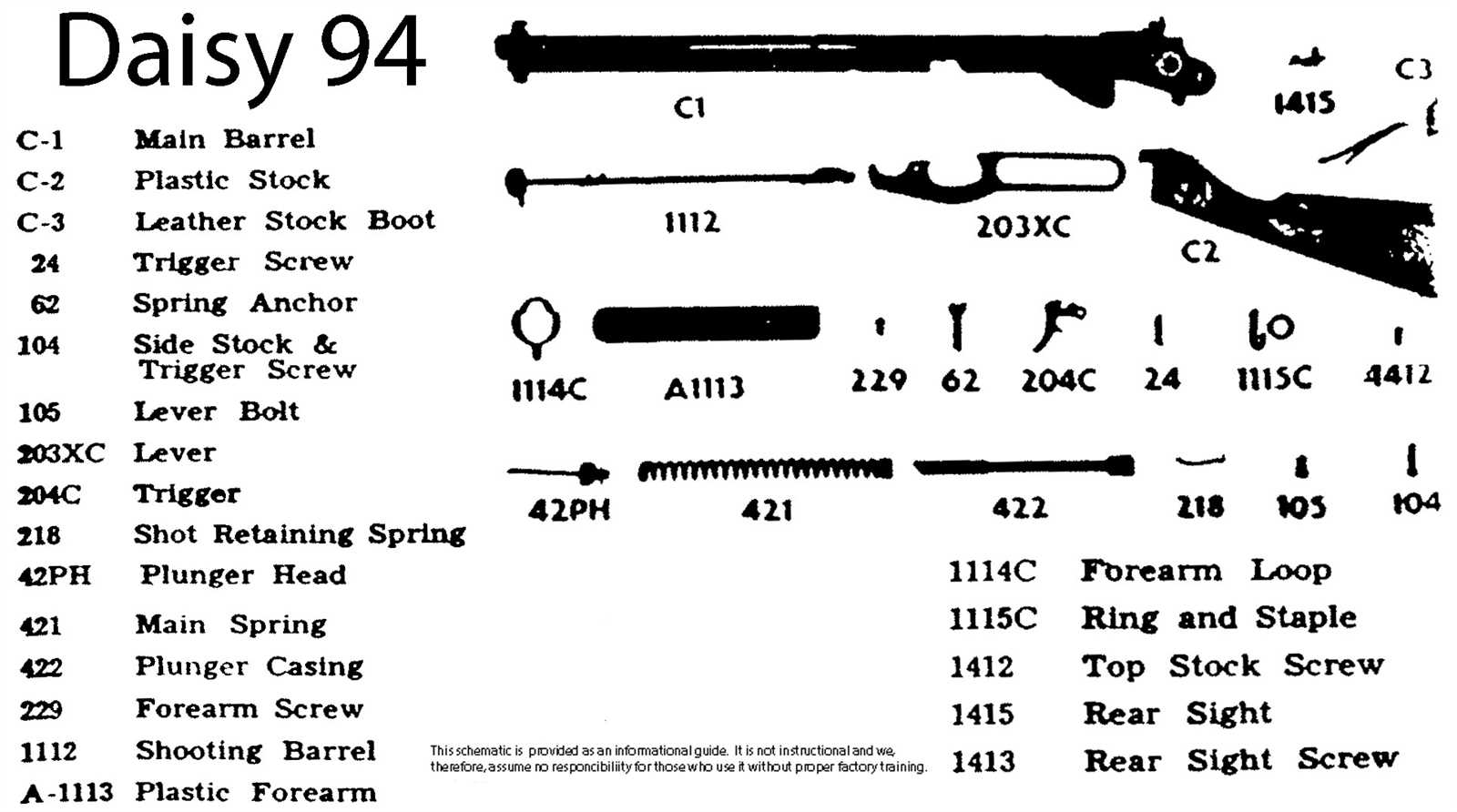

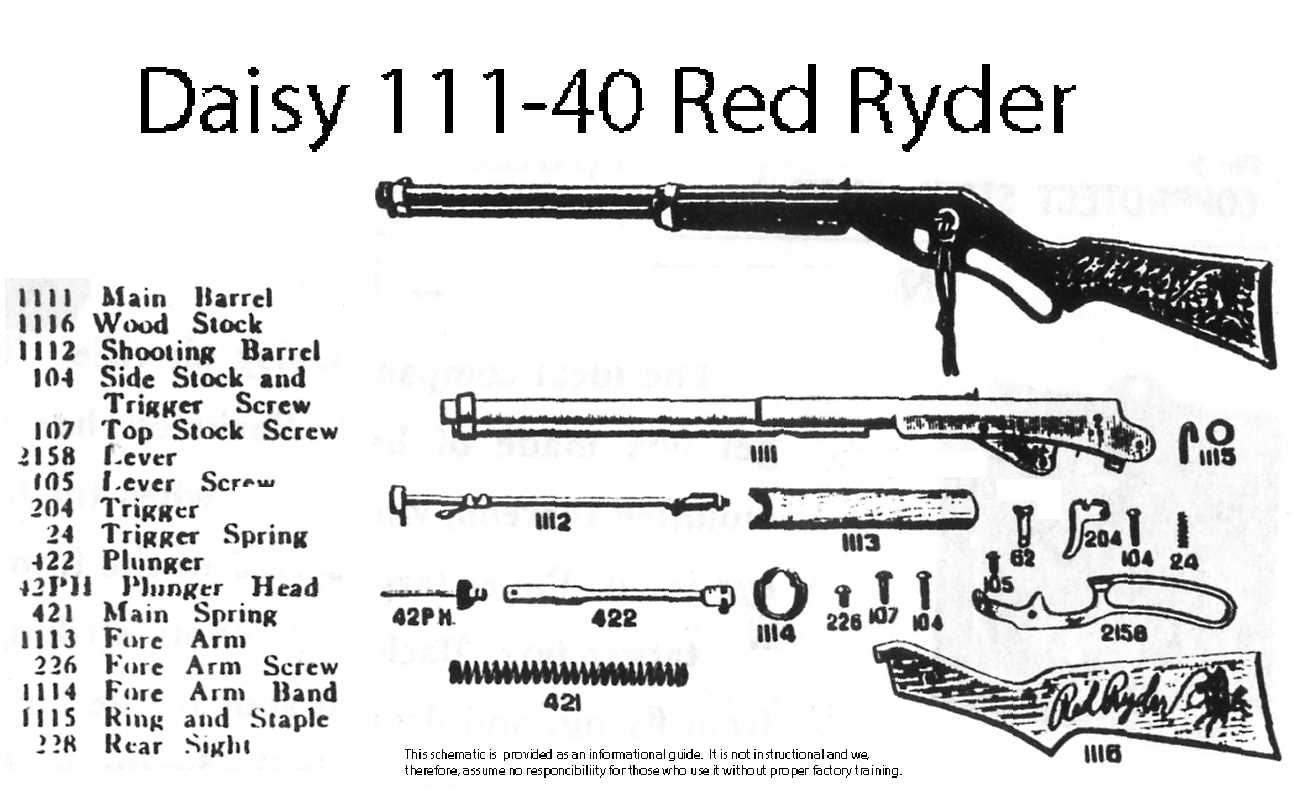

Interpreting a visual representation of an air rifle’s components requires a clear understanding of how each part is labeled and organized. These illustrations are designed to provide a detailed overview of the assembly, showing each individual element and its relationship to others. Knowing how to read these images allows for more effective repairs and maintenance.

Identifying Each Component

The first step in reading an illustration is identifying each labeled part. Typically, numbers or letters are used to reference specific elements, which correspond to a list of descriptions. Understanding the shape, function, and location of each item helps you quickly find the necessary components when performing tasks like replacing a spring or adjusting the trigger mechanism.

Understanding Part Interactions

Once the individual parts are identified, the next step is understanding how they work together within the assembly. Many components are interconnected, meaning their operation relies on the proper alignment and functioning of others. By carefully analyzing the diagram, you can determine how parts interact, which is crucial for diagnosing issues or performing a successful repair.

Common Repair Tips for Red Ryder

Maintaining and repairing an air rifle can seem challenging, but with the right approach, most issues are manageable. Understanding the common problems that arise and knowing how to address them can save time and money. This section covers helpful tips for performing basic repairs and keeping your air gun in top condition.

One frequent issue is the loss of power or inconsistent firing. This could be caused by a number of factors, such as a worn-out spring or a malfunctioning trigger. Regularly inspecting these components and replacing any worn parts can prevent performance issues. It’s also important to lubricate moving parts to ensure smooth operation and reduce wear.

If the barrel becomes misaligned or the gun experiences difficulty when cocking, it’s essential to check the internal components for damage or blockages. Cleaning and re-aligning the barrel can often restore proper function. Be sure to follow the manufacturer’s instructions for reassembly to avoid causing further damage.