When it comes to maintaining fishing reels, having a clear understanding of their individual components and how they fit together is essential for smooth operation. Whether you’re repairing an old model or assembling a new one, knowing the parts and their functions ensures better performance and longevity. A detailed guide to reel construction helps in troubleshooting and addressing any issues that may arise during use.

Each reel is made up of various elements, from the spool to the internal gears, each playing a crucial role in its overall function. Identifying these components and understanding their relationships will allow you to perform more precise maintenance or repairs when needed. This can be especially helpful for avid anglers who rely on their equipment for consistent performance in different conditions.

Knowing how to assemble and disassemble the reel efficiently is a valuable skill. Understanding the purpose of each piece, such as the drag system or the anti-reverse mechanism, provides greater insight into the tool’s mechanics. This knowledge not only aids in repairs but also improves the overall fishing experience by ensuring the reel functions as intended.

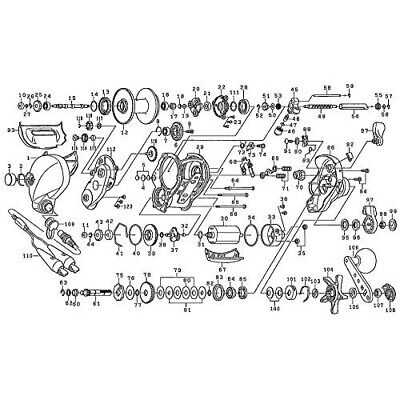

Daiwa BG 4000 Parts Breakdown

In order to properly maintain or repair a fishing reel, it is important to understand the specific components that make up the assembly. Each element plays a vital role in ensuring smooth operation, from the spool to the internal mechanisms. A breakdown of these individual components can help you identify issues and perform necessary repairs or upgrades.

The exterior casing houses many internal parts that work together to provide functionality. These include the handle, drag system, and brake mechanisms, all crucial for the reel’s performance. Inside, you’ll find the gears, bearings, and shafts that transfer power and allow for smooth line retrieval. Understanding how these elements interact helps in troubleshooting and ensures better longevity of the equipment.

Focusing on key components such as the anti-reverse system, gear ratio, and spool capacity can give a clearer picture of how the reel functions under different conditions. Whether you are assembling a new model or performing maintenance on an existing one, having a detailed knowledge of these elements allows for precise adjustments and repairs to keep the reel working at its best.

Identifying Key Components of the Reel

Understanding the main components of a fishing reel is essential for proper maintenance and repair. Each part serves a unique function, working in unison to provide smooth operation and efficiency. From the outer casing to the internal mechanisms, knowing what each piece does helps in identifying potential issues and making precise adjustments when necessary.

One of the most important elements is the spool, which holds the fishing line and controls its release. The drag system regulates tension on the line to prevent breakage during a fight with a fish. Additionally, the gears inside the reel control the speed and efficiency of line retrieval, while the anti-reverse system ensures that the handle does not rotate backward during use.

By recognizing the role of each component, you can diagnose problems more effectively and perform maintenance tasks with greater accuracy. This knowledge helps extend the lifespan of the reel and ensures its optimal performance in various fishing environments.

Understanding the Assembly Process

Assembling a fishing reel requires careful attention to detail, ensuring that each component is correctly positioned to work in harmony with the others. The process involves multiple steps, each crucial for the proper functioning of the reel. From placing the internal gears to securing the outer casing, understanding how the parts fit together ensures a smooth assembly and helps prevent operational issues.

Step-by-Step Assembly

The first step in assembly involves placing the main gear and pinion gear, ensuring they mesh perfectly for smooth retrieval. Next, the drag system is installed, followed by the spool and handle. Each part should be carefully aligned to avoid wear and tear during use. Securing the components in their proper positions ensures that the reel functions as intended, offering durability and reliable performance on the water.

Importance of Proper Alignment

Alignment is key in the assembly process, as even slight misalignments can affect the reel’s efficiency. A poorly aligned gear system, for example, can result in slower line retrieval or unnecessary strain on the internal components. By following the assembly instructions and double-checking each step, you ensure that the reel performs optimally and avoids unnecessary repairs.