Maintaining agricultural equipment is crucial for ensuring optimal performance. One of the key factors in proper upkeep is understanding the structure and individual components of the machinery. By breaking down the machine’s elements, it becomes easier to identify any potential issues and resolve them quickly, enhancing efficiency and longevity.

In this section, we will explore how to effectively interpret the layout of your equipment, offering guidance on recognizing each part’s role in the overall system. A clear understanding of how these components interact can help with troubleshooting and improve your ability to make repairs when needed.

Familiarizing yourself with the structure allows for quicker diagnostics, saving time and resources in the long run. By following the outlined approach, you’ll be equipped with the knowledge to maintain and repair your machinery confidently and independently.

Understanding Equipment Components

To ensure your agricultural machinery operates at peak performance, it is essential to have a clear understanding of its various elements. Each piece plays a vital role in the overall functionality, and knowing their specific functions helps prevent breakdowns and inefficiencies. A well-maintained machine not only lasts longer but also performs better, saving time and money on repairs.

The layout of your equipment is carefully designed to achieve optimal results. Each component, from pumps to valves, is interconnected, and understanding how they work together allows for more effective troubleshooting and repair. By recognizing the purpose of each part, you can identify potential issues before they escalate, ensuring smooth operation in the field.

Familiarizing yourself with these components also helps when it comes to replacing or upgrading specific parts. With a solid grasp of how everything fits together, you can make informed decisions about repairs and enhancements, ultimately increasing the longevity and efficiency of your machinery.

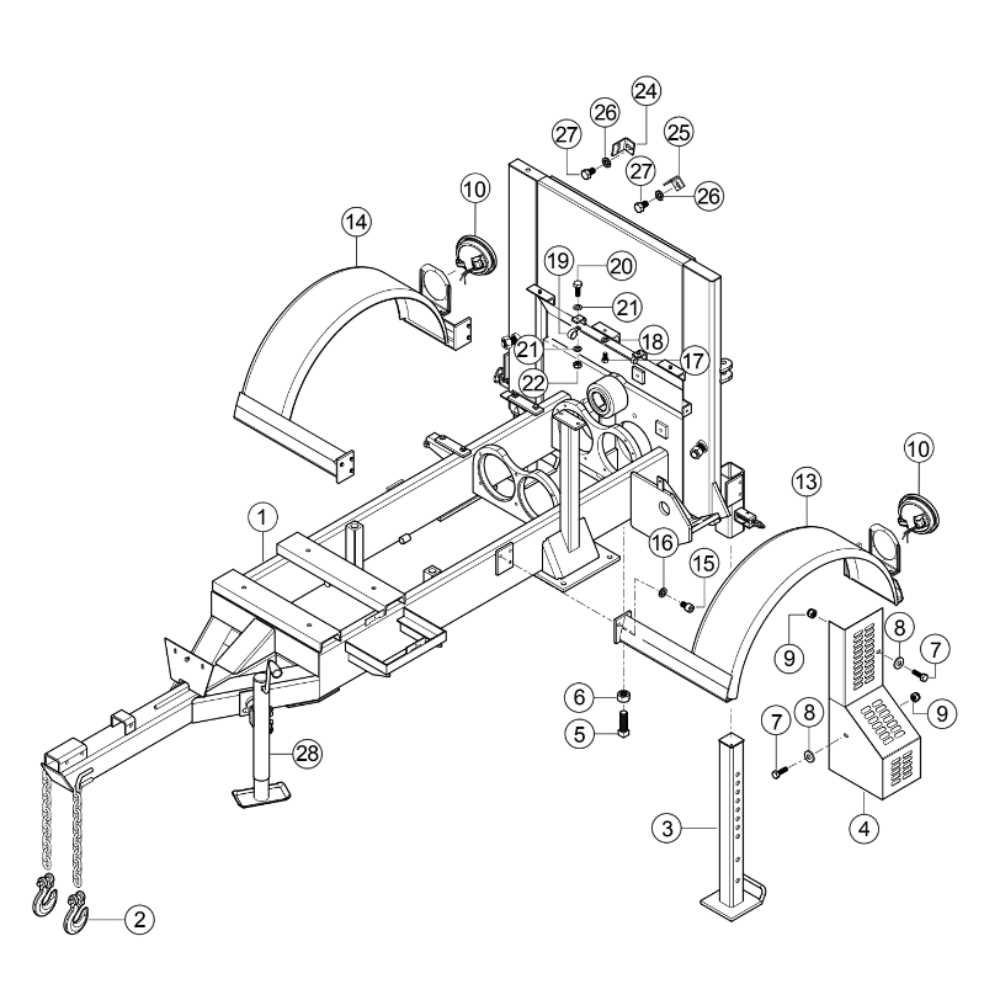

How to Read Equipment Assembly Layout

Understanding the layout of your machinery is an essential skill for efficient maintenance. By interpreting the schematic representations, you can identify the individual components and their relationships to one another. This knowledge is crucial for troubleshooting issues, performing repairs, or replacing damaged elements.

Each layout typically includes labels, numbers, or symbols that correspond to specific components within the system. To interpret these accurately, it is important to familiarize yourself with the key terminology and symbols used in the guide. Cross-referencing these labels with the machinery manual ensures clarity when identifying parts and understanding their functions.

Additionally, most schematics are organized to show how different sections of the machine interact. By following the flow of the diagram, you can trace connections and pinpoint areas where malfunctions may occur. This methodical approach enhances your ability to maintain and repair equipment efficiently, minimizing downtime.

Common Issues with Equipment Components

Like any complex machinery, equipment used in agricultural processes can encounter various issues over time. Recognizing common problems early on can help prevent further damage and ensure the machine operates efficiently. Many issues arise from wear and tear, improper maintenance, or even environmental factors that affect specific elements of the system.

Clogging and Blockages

One of the most frequent issues that arise is the clogging of fluid delivery systems. Over time, debris, chemicals, or residue can build up inside pipes, valves, or nozzles, causing reduced performance or complete blockages. Regular inspection and cleaning of these components are essential to avoid disruptions during operation.

Leaks and Seal Failures

Leaks are another common problem that can lead to significant performance drops. Seals and gaskets may wear out or become damaged, allowing fluid to escape. It’s important to check seals regularly and replace them when necessary to maintain the system’s integrity. A timely inspection can save considerable effort and prevent further damage.

Proper maintenance and early detection of these issues are key to keeping your equipment running smoothly. Regularly checking connections, cleaning filters, and replacing worn-out parts will extend the life of your machinery and improve its overall efficiency.