When maintaining and repairing your woodworking equipment, having a clear understanding of each individual component is essential. A comprehensive breakdown can save time and effort, allowing you to quickly identify parts that may need replacement or adjustment. By gaining familiarity with the inner workings of your machine, you can ensure it operates at peak performance for longer periods.

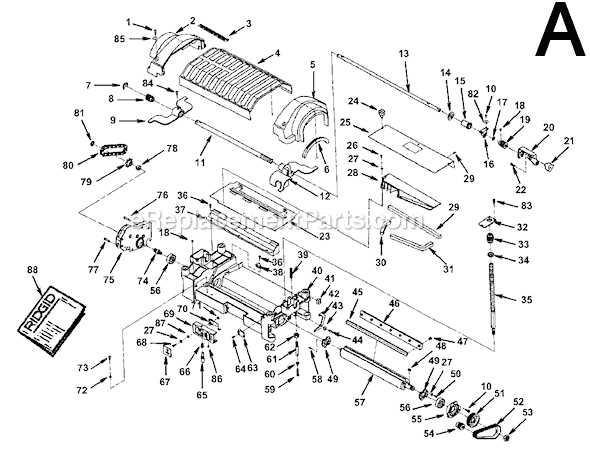

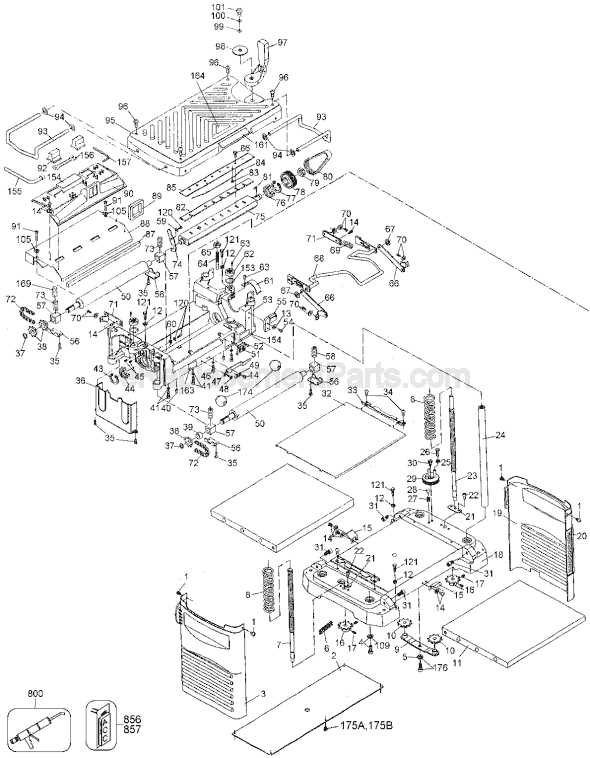

Tools like these consist of numerous interconnected elements, each serving a specific function. Whether it’s the cutting mechanism, the feed system, or the motor, recognizing these components is key to effective troubleshooting. With a visual reference, it’s easier to locate the exact part you need and understand how it interacts with other components for optimal performance.

Proper knowledge of your tool’s design can also help you avoid common mistakes, reduce the likelihood of wear and tear, and extend the lifespan of your equipment. Whether you’re an amateur hobbyist or a professional craftsman, understanding the structure of your machine is invaluable for keeping it running smoothly.

Understanding Dewalt 735 Planer Parts

Knowing the different elements of your woodworking tool and how they function together is essential for effective use and maintenance. Each component plays a specific role in the overall performance, and understanding this structure helps to keep the machine running efficiently. When you’re able to identify each piece, it becomes easier to troubleshoot and resolve issues without unnecessary delays.

Key Components of the Machine

The machine consists of several critical sections that work in unison to provide smooth, precise cuts. These include the cutting mechanism, the feed system, and the motor housing. Each of these systems contains multiple sub-components, such as blades, rollers, and gears, that allow the tool to perform its tasks with high accuracy. Understanding how these sections interconnect allows for easier identification of issues when they arise.

How to Locate and Identify Each Part

Referencing a clear and detailed visual guide is an effective way to identify specific components. These guides provide a labeled view of the tool, allowing you to quickly locate each individual piece and understand its function within the broader system. Knowing where each part is located and how it interacts with others will help during maintenance, repairs, and part replacement, ensuring the machine continues to operate smoothly.

Identifying Key Components of the Planer

Understanding the key elements of your woodworking machine is crucial for proper use and upkeep. Each component plays an important role in ensuring the tool performs at its best. When you can identify and recognize the functions of these components, you’ll be better equipped to address issues and maintain optimal operation.

Some of the most essential parts include the cutting mechanism, which is responsible for removing material from the workpiece, and the feed system, which controls the movement of the material through the machine. Additionally, the motor housing and control panel are vital for operation, as they power and manage the tool’s performance. Familiarizing yourself with these main sections will make troubleshooting and repairs more straightforward.

How to Use the Parts Diagram for Repairs

When performing maintenance or repairs on your tool, a clear visual reference is essential for identifying faulty components. A well-detailed illustration allows you to quickly locate specific parts and understand how they fit into the larger system. This approach not only saves time but also ensures you can make informed decisions when it’s time to replace or adjust any element of the machine.

Step-by-Step Identification Process

Start by examining the guide to familiarize yourself with the layout of the machine. Look for the numbered or labeled parts, which will correspond to the various sections within the tool. Pay close attention to any components that appear worn or damaged, and match them to the corresponding part on the visual reference. This will help you pinpoint exactly what needs to be replaced or repaired.

Ordering and Replacing Parts

Once you have identified the faulty part, use the diagram to find the exact model number and specifications. This will ensure you order the correct replacement part, avoiding confusion or mistakes. After receiving the new component, follow the instructions from the diagram to properly install the piece, making sure everything aligns correctly. By using the visual guide in this way, you can make repairs efficiently and keep your tool working like new.