When working with any power equipment, it’s crucial to understand its internal structure. Knowing the layout of individual components can make repairs and maintenance much easier. This knowledge ensures better handling of the tool and extends its lifespan by allowing you to address issues as they arise.

In this section, we’ll break down the various elements that make up the tool. Whether you’re troubleshooting or performing routine upkeep, understanding how these parts interact is essential for efficient operation. Knowing each part’s role and how they fit together will give you confidence when servicing your equipment.

Repairing or replacing parts becomes much simpler when you can identify which component is malfunctioning. Familiarity with the internal setup enables you to address problems quickly, saving both time and effort. By the end of this guide, you’ll have a clearer understanding of how to manage and maintain your tool effectively.

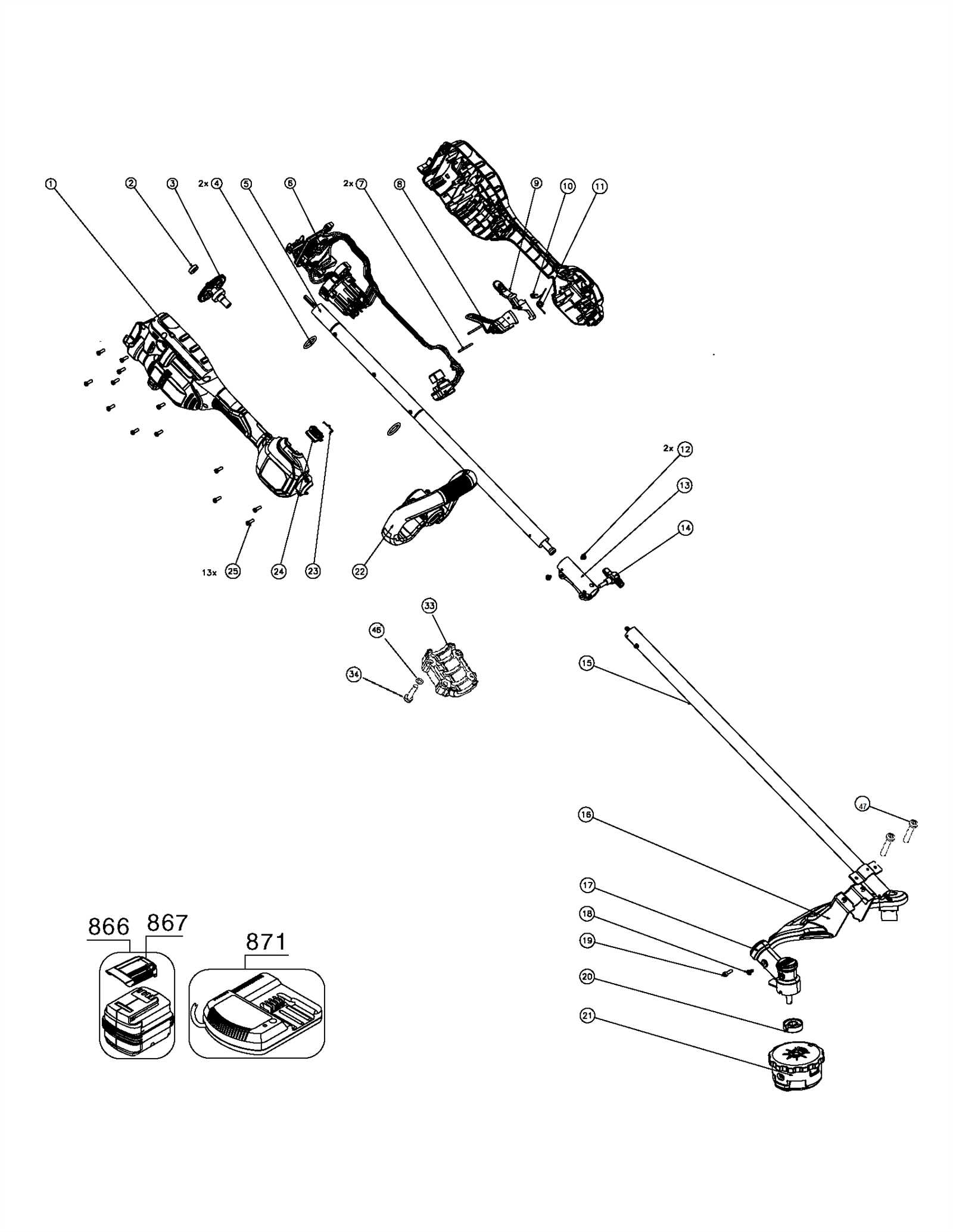

Understanding the Dewalt DCST922 Parts Layout

Having a clear understanding of the internal configuration of any power tool is vital for maintaining its functionality and ensuring long-term performance. This section focuses on how the key components of the tool are arranged and how they work together. By examining the structure, users can identify potential weak points and areas requiring attention during maintenance or repair.

Key Components and Their Interaction

At the core of every tool are the main elements that enable it to perform its intended tasks. These components are carefully designed to work in harmony, providing both power and stability. Understanding the role of each piece in the assembly helps ensure that the tool runs efficiently and safely. From the motor to the trigger mechanism, each part is essential for smooth operation.

Visualizing the Layout for Easy Maintenance

A well-organized internal layout simplifies any repair or maintenance process. By learning how each component is arranged, users can troubleshoot issues more effectively, pinpointing the cause of a malfunction without unnecessary disassembly. Visualizing this structure allows for quicker fixes and ensures that every part is in its correct position for optimal performance.

Identifying Key Components and Their Functions

Each power tool consists of several essential elements that contribute to its overall functionality. Understanding the role of these components allows users to maintain, repair, and optimize their equipment efficiently. Identifying which part serves what purpose is key to diagnosing problems and ensuring smooth operation.

In any tool, the motor is the driving force behind its performance, converting electrical energy into mechanical power. The trigger mechanism regulates the flow of energy, providing the user with control over the device’s intensity. Other components, such as gears and handles, provide structural support and assist in transferring power effectively. Familiarity with the function of each part ensures that you can keep your equipment working at its best.

Step-by-Step Guide to Assembly and Maintenance

Proper assembly and regular maintenance are crucial to ensuring the longevity and optimal performance of any power tool. Following a systematic approach helps you avoid mistakes and identify issues before they become major problems. This guide will take you through the essential steps for assembling and maintaining your equipment with precision.

Start by carefully reviewing the user manual to ensure that all parts are accounted for and correctly positioned. Assembly should be done with attention to detail, ensuring that each component fits securely into place. Once assembled, regular upkeep, including cleaning and lubrication of moving parts, will help maintain smooth operation and reduce wear. Periodic checks of the electrical components and motor will prevent potential breakdowns, keeping your tool in peak condition.