When it comes to the efficient operation of any power tool, knowing the key components that make up the device is essential. These individual pieces work in unison to ensure smooth functionality, and understanding their roles can make maintenance and repairs much easier. Whether you’re a DIY enthusiast or a professional, a comprehensive grasp of how each element fits together helps prolong the life of your equipment.

In this guide, we will explore the different sections of a power tool, outlining how each part contributes to its overall performance. By identifying the crucial components, you’ll gain insight into how to troubleshoot, repair, and even upgrade your tools when needed.

Proper maintenance and timely replacement of worn-out components are vital for keeping your equipment in top shape. Familiarity with the internal structure allows users to handle repairs with confidence, reducing downtime and ensuring that the tool remains efficient throughout its lifespan.

Understanding Power Tool Components

Each power tool consists of several critical elements that work together to perform specific tasks. These components are designed to enhance the efficiency, durability, and precision of the tool. Recognizing how each part functions allows users to better understand the overall mechanism and contribute to its proper maintenance and repair.

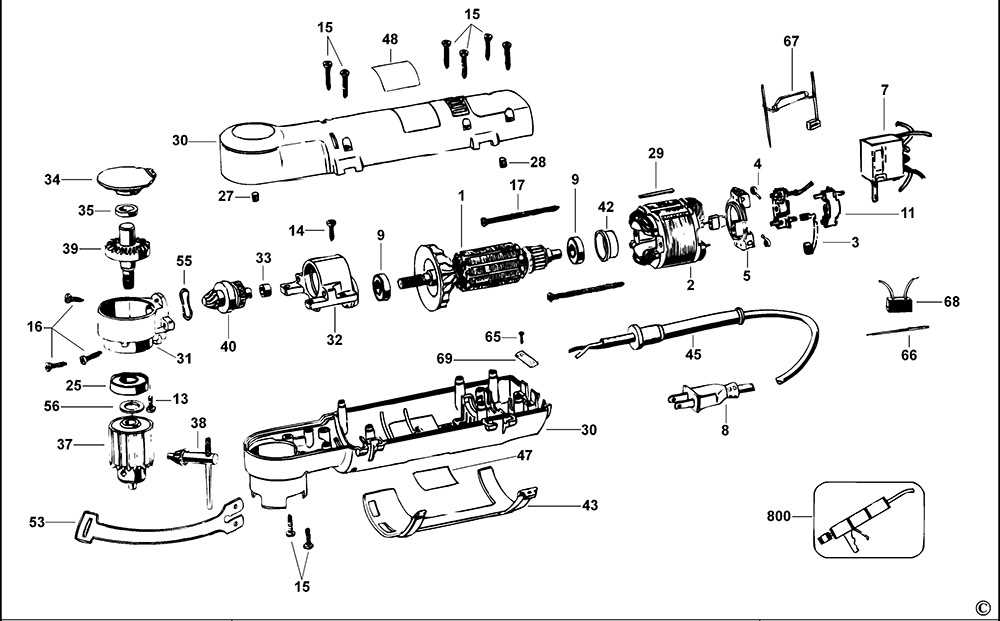

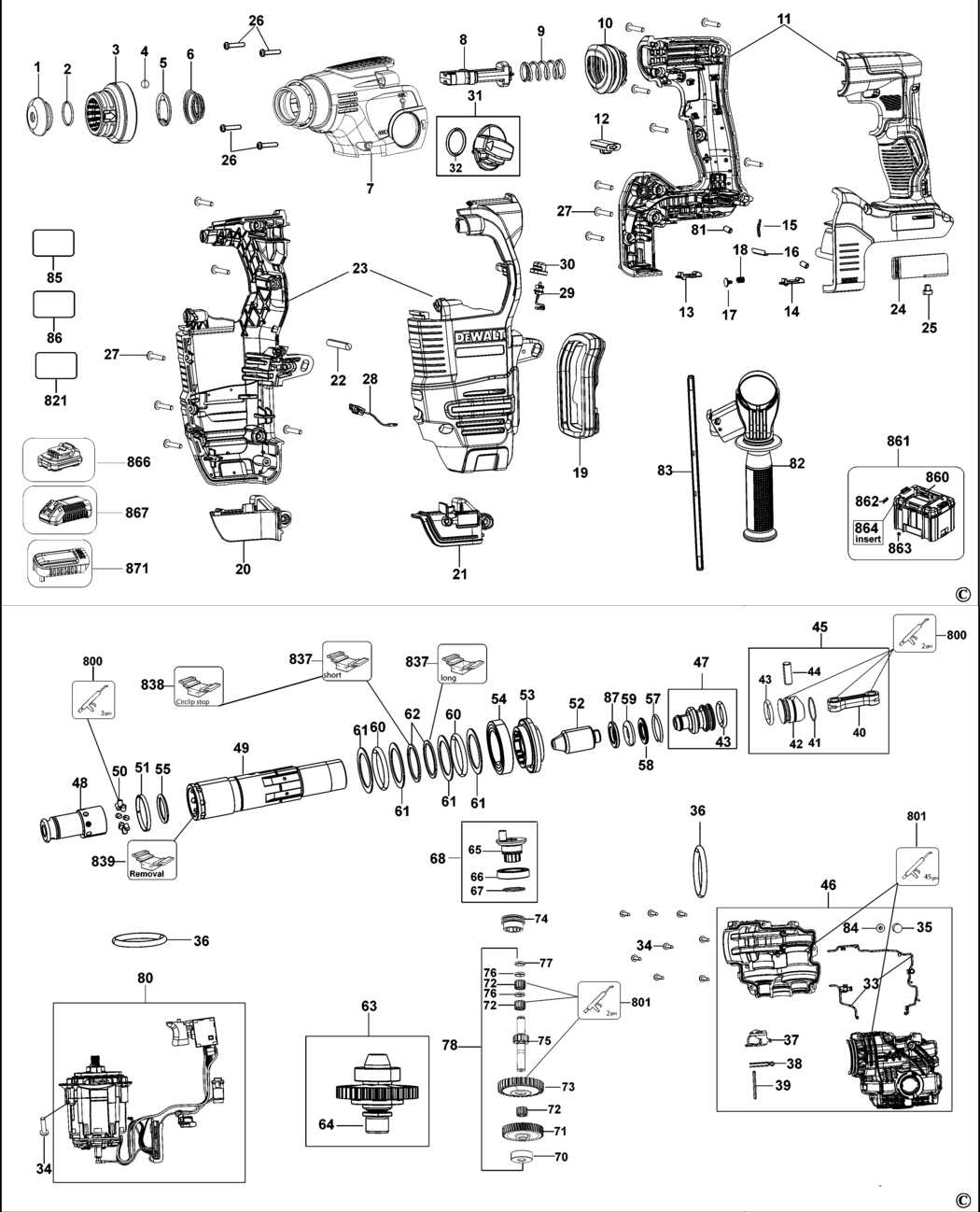

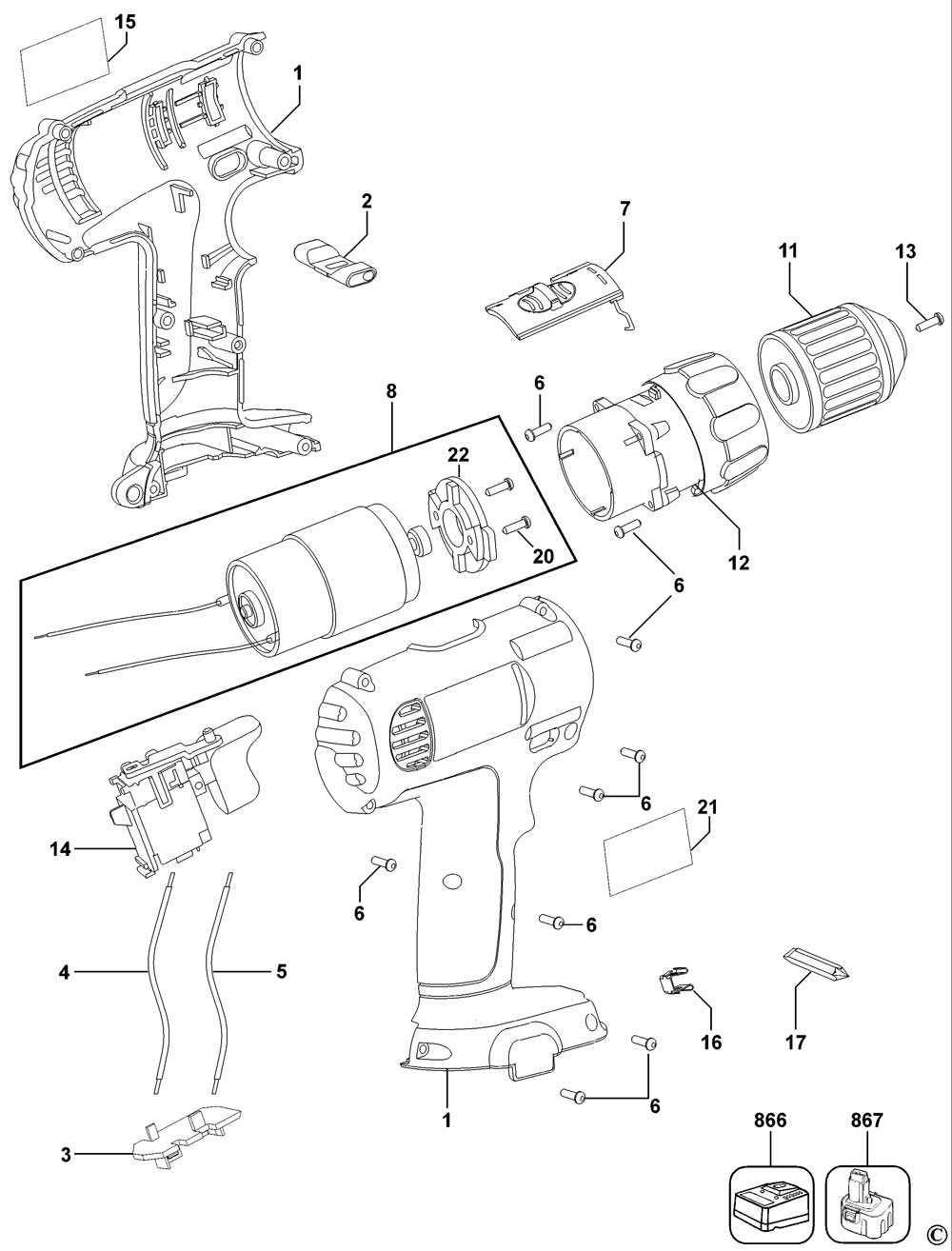

The core assembly of a power tool includes motors, gears, switches, and housing. Each piece is carefully crafted to ensure that the tool operates smoothly, delivering consistent performance. Identifying these elements is the first step in troubleshooting issues, replacing damaged components, or upgrading to improve functionality.

Knowing the role of each part helps users in selecting the right replacement pieces when repairs are needed. Proper upkeep and the ability to address potential problems can extend the lifespan of any tool, ensuring it remains effective for years to come.

Identifying Key Parts in Power Tools

Every tool is made up of several crucial components that contribute to its functionality. Recognizing these key elements is essential for anyone looking to repair, maintain, or optimize their equipment. Understanding how each section works ensures that you can identify any issues and address them efficiently.

Motor and Gear Mechanism

The motor is the heart of any power tool, providing the necessary energy to perform tasks. It is closely connected to the gear system, which translates the motor’s power into rotational force. This combination drives the overall performance of the tool, making it critical to understand how both parts interact for effective operation.

Switches and Housing

The housing protects the internal components from damage, ensuring the safety and longevity of the tool. Switches control the tool’s operation, offering an easy way to turn it on and off. Being able to locate and understand the function of these pieces is essential for troubleshooting and repairs.

How to Maintain Power Tool Components

Proper maintenance is essential for keeping any tool in top condition, ensuring that all its key components continue to work effectively. Regular care not only extends the lifespan of your equipment but also improves its performance, reducing the need for costly repairs. By understanding how to care for individual elements, you can ensure smooth operation over time.

Cleaning and Lubrication

Regular cleaning is one of the most important aspects of maintenance. Dirt and debris can accumulate in the tool, affecting its efficiency. Lubricating moving parts helps reduce friction, ensuring that everything operates smoothly. Always use the appropriate lubricants to avoid damaging internal components.

Inspecting and Replacing Worn Elements

Frequent inspections are crucial for identifying worn or damaged components. Pay close attention to elements such as the motor, gears, and switches. If any part shows signs of wear or malfunction, replacing it promptly prevents further damage and ensures that the tool operates at full capacity.