When working with power tools, it’s crucial to understand the essential components that make up the mechanism. These devices are built with intricate parts that work together to provide optimal performance. A clear understanding of how each element functions and fits into the overall system ensures better maintenance and efficient repair processes.

For tool owners, knowing the structure of the inner workings can help troubleshoot common issues, identify worn-out components, and enhance the longevity of the equipment. By exploring the individual parts and their relationships, users can gain the confidence needed to tackle repairs and ensure smooth operation over time.

Regular maintenance and familiarity with the tool’s layout are key to ensuring both safety and reliability. Having access to accurate assembly information makes all the difference when it comes to achieving consistent results and extending the lifespan of your equipment.

Understanding Power Tool Components

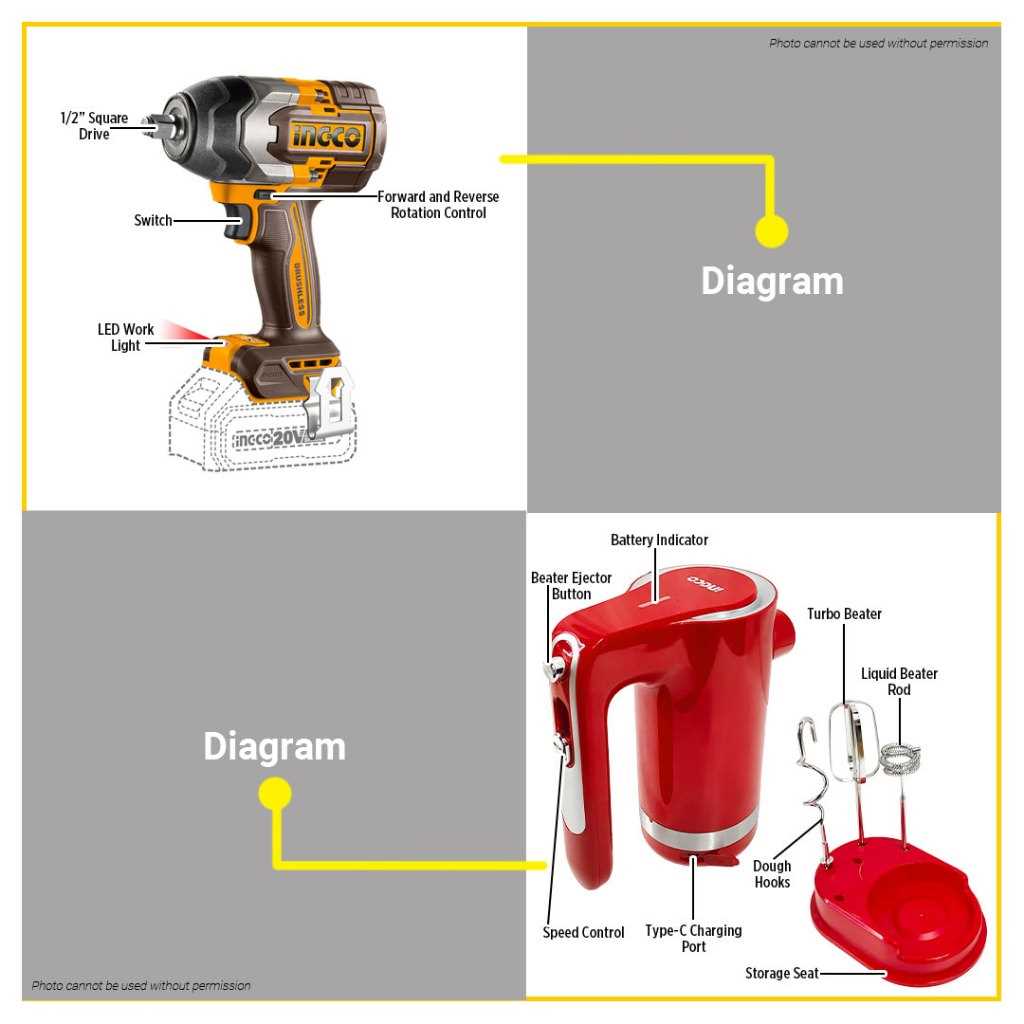

Power tools consist of various critical elements that each play a unique role in the device’s functionality. From the motor to the housing, each component is carefully designed to work in harmony, ensuring efficient performance. Understanding these individual components and their interactions helps users make informed decisions when it comes to troubleshooting or upgrading their equipment.

The central parts typically include the mechanism that provides rotational force, the switches for control, and the housing that protects internal components. Each of these is essential for the overall efficiency of the tool. Familiarity with how these elements fit together can assist in diagnosing common issues, such as power loss or mechanical failure.

By gaining insight into the structure and purpose of each part, users can also take preventive measures to avoid unnecessary wear and tear. Proper care and maintenance of the tool’s critical components will prolong its lifespan and maintain its peak performance.

Step-by-Step Breakdown of Key Parts

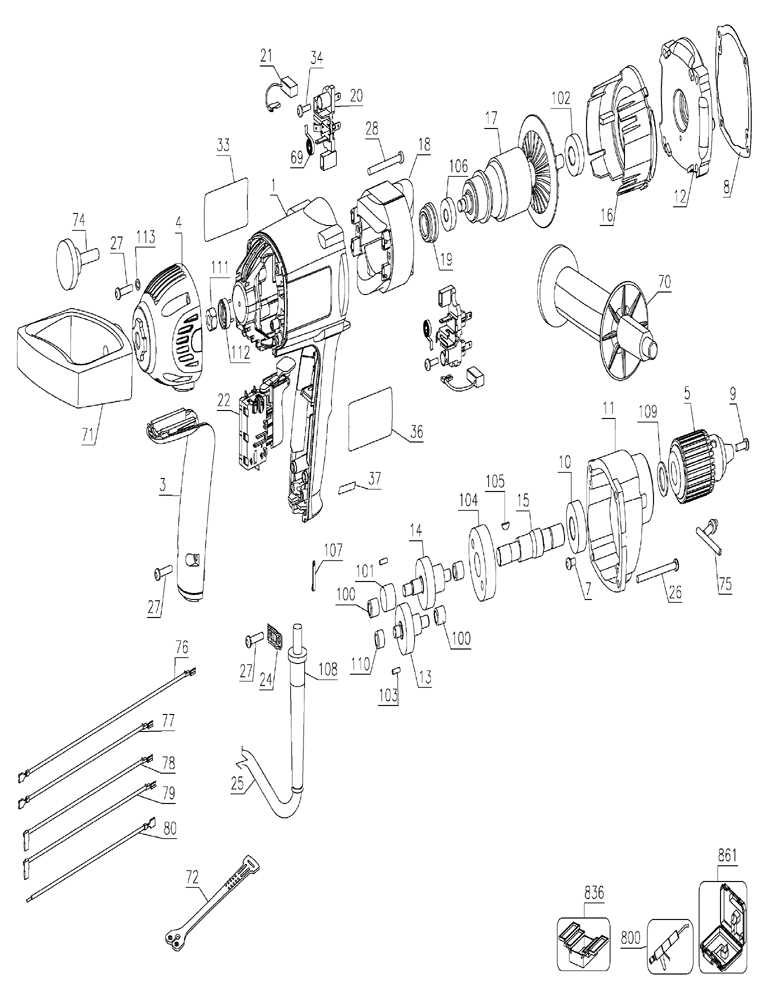

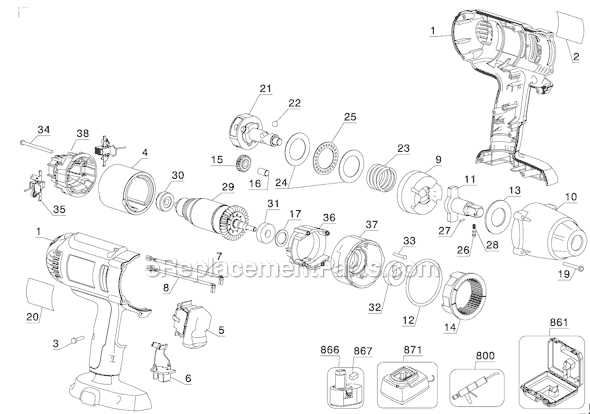

Every tool is made up of several integral elements that perform specific functions to ensure smooth operation. Understanding these components and how they work together is crucial for effective maintenance and repair. A methodical approach to identifying each key part can help users recognize issues quickly and solve them efficiently.

The motor is typically the heart of the device, generating the energy required for movement. Connected to this is the gear system, which regulates and directs the power to the tool’s active components. Another important part is the trigger or switch mechanism, responsible for controlling the device’s power and speed. Each of these elements contributes to the overall functionality and performance of the tool.

Protecting the internal workings is the outer casing, which shields all components from damage and ensures durability during regular use. Without understanding the importance of each part, it would be difficult to properly maintain or replace worn-out elements. Being able to identify the role of each part is an essential step toward maximizing the tool’s lifespan and performance.

Common Issues with Power Tools

Like any mechanical device, power tools are prone to wear and tear over time. Understanding the most common issues that can arise with these tools helps users address problems promptly and maintain peak performance. Whether it’s a lack of power, malfunctioning components, or difficulty in operation, recognizing early signs of trouble can save time and money on repairs.

One frequent issue is the tool losing power or not turning on at all. This can be caused by a faulty switch, battery connection problems, or a malfunctioning motor. Another common problem is excessive vibration or noise during use, often indicating a misalignment in the internal components or a worn-out gear system. Additionally, tools may struggle with maintaining torque, resulting in poor performance when handling heavy-duty tasks.

Addressing these issues involves diagnosing the root cause, which may require inspecting individual components for wear, damage, or obstructions. Regular maintenance, such as cleaning and lubricating moving parts, can prevent many of these common problems from occurring and ensure the tool continues to perform optimally.