When working with power tools, it’s essential to have a clear understanding of their internal structures. Knowing how the various components work together ensures effective usage and easy maintenance. In this guide, we explore the critical elements of a particular tool, focusing on the key mechanisms that contribute to its functionality.

Each machine has unique parts that perform specific tasks, making it crucial to identify and maintain them properly. Familiarity with these elements helps in troubleshooting and replacing damaged components, leading to longer tool lifespan and better overall performance. Here, we break down the components in an accessible way, offering insights into how each part interacts with the others to achieve optimal results.

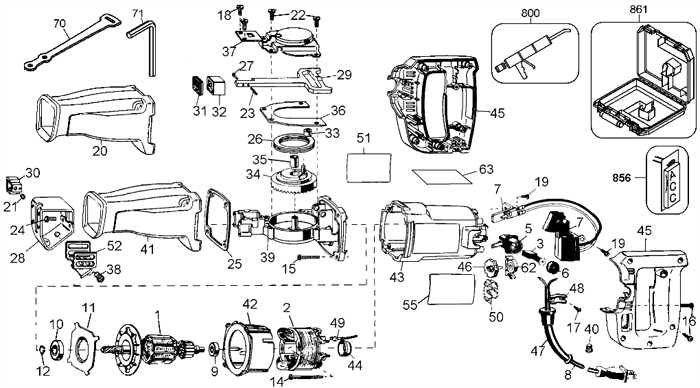

Dewalt Reciprocating Saw Components Overview

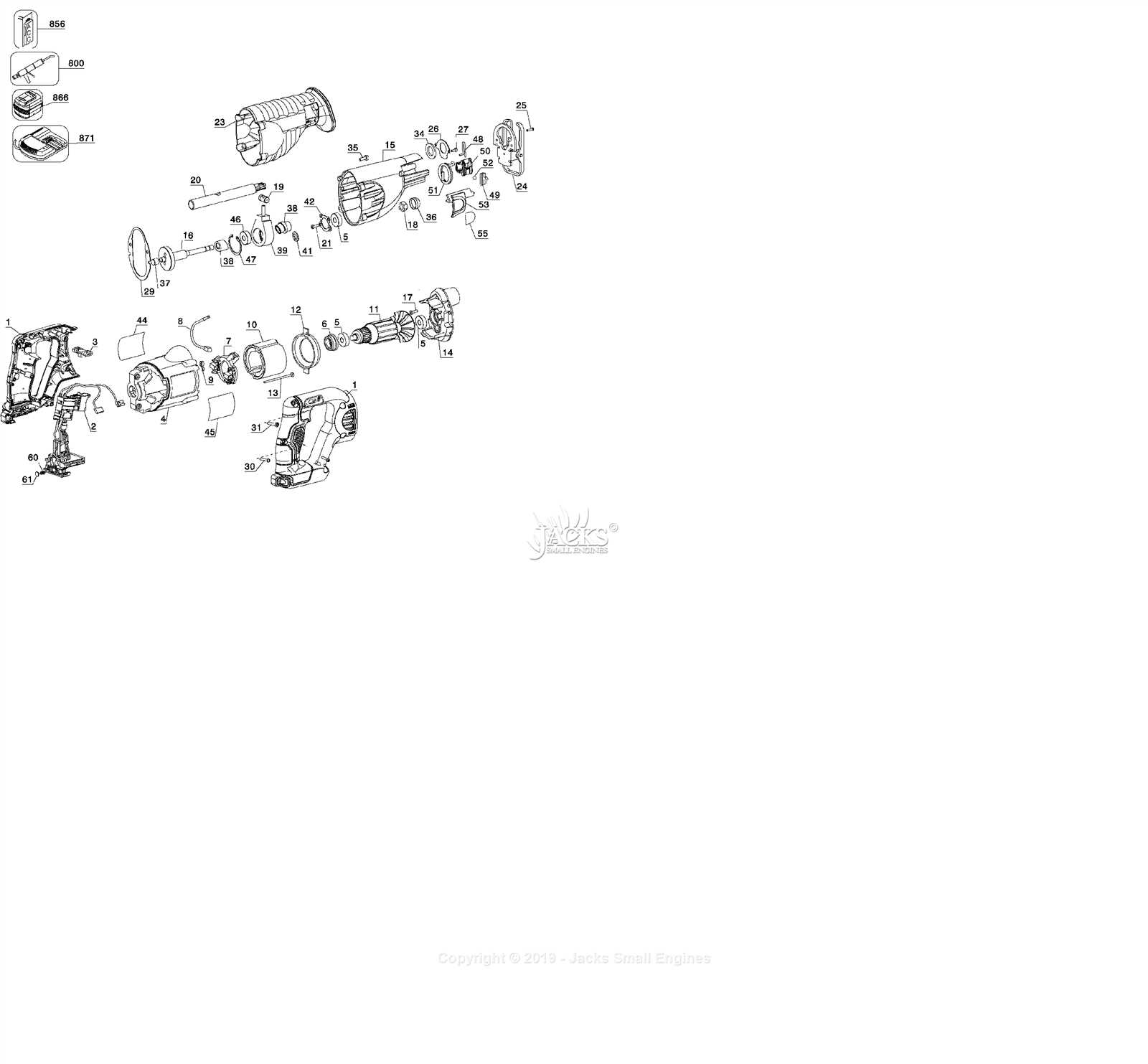

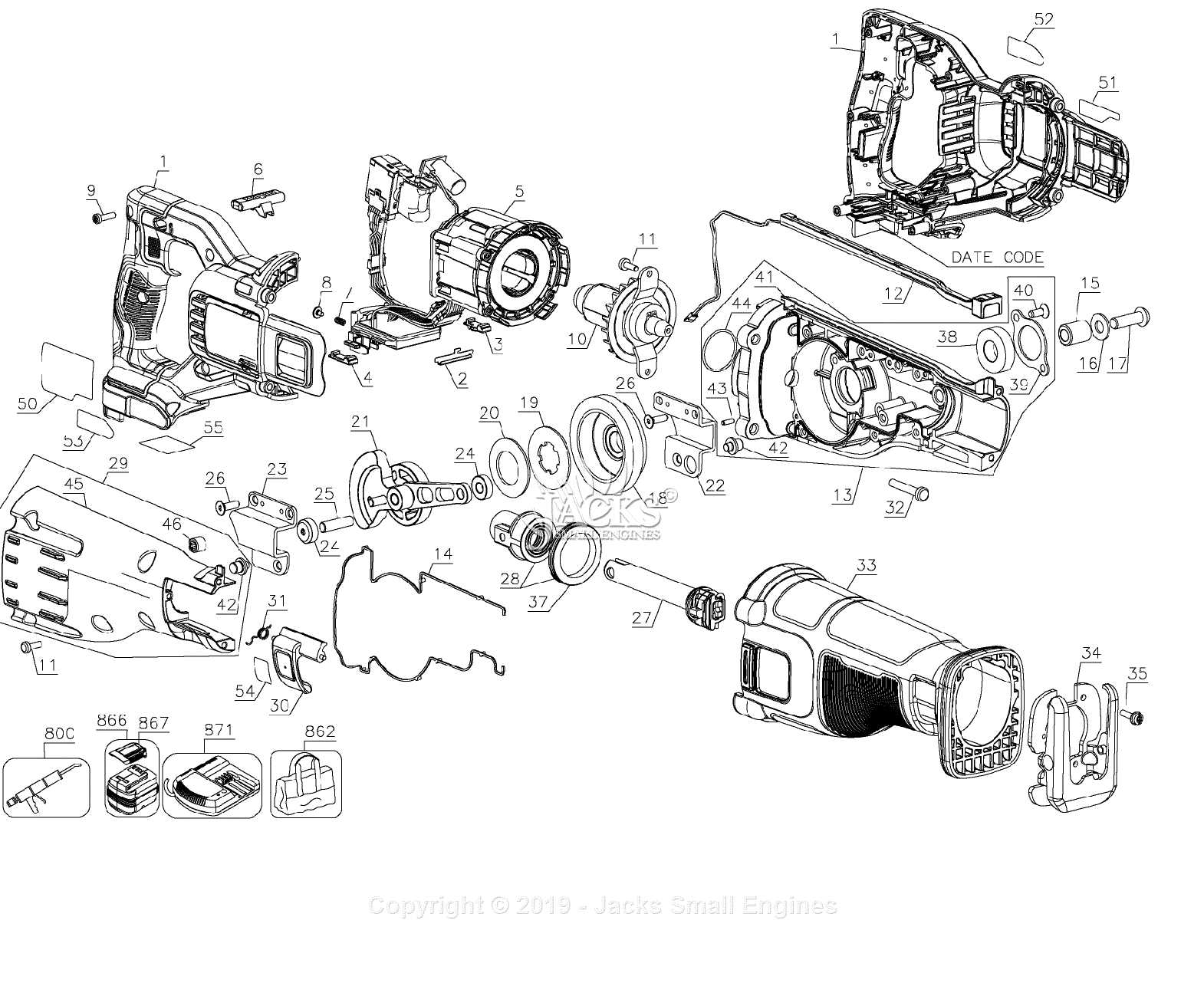

To fully understand the functioning of any power tool, it’s important to familiarize yourself with its primary mechanisms. These essential elements come together to provide smooth operation and efficient performance. Knowing their specific roles allows users to troubleshoot, maintain, and repair the tool as needed. In this section, we will explore the core components that make up a cutting-edge model, outlining their individual responsibilities and their contribution to the tool’s overall functionality.

Key Mechanisms and Their Functions

Every tool has specific components designed to handle particular tasks. From the motor that powers the system to the protective casing that ensures safety, each element is engineered for a precise purpose. Understanding how these mechanisms interact with one another helps in diagnosing issues and performing routine maintenance. This knowledge also aids in identifying which parts may need replacement after extended use.

Interconnectedness of Tool Elements

The effectiveness of the tool depends on the seamless integration of its various parts. Some components work in tandem, while others perform independent functions that contribute to the machine’s overall performance. By understanding this interconnectedness, users can enhance their ability to use the tool efficiently and ensure it remains in top condition for years to come.

Identifying Key Parts for Maintenance

Regular upkeep of power tools is essential for maintaining optimal performance and longevity. Identifying the most crucial components for maintenance helps ensure the tool operates smoothly and efficiently over time. By focusing on the right areas, users can address potential issues before they affect the functionality of the machine. In this section, we will outline the key parts that require regular inspection and care to keep the tool in peak condition.

Essential Mechanisms to Monitor

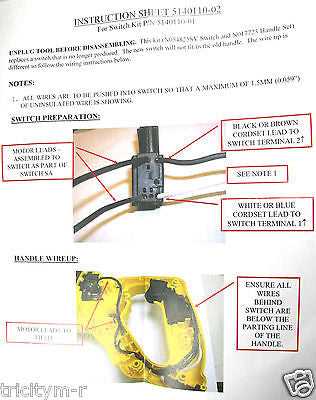

Among the most important parts to check are the motor, trigger mechanism, and housing. These elements are responsible for powering the tool, controlling its operation, and protecting the internal components from damage. Regular cleaning and lubrication can help prevent wear and tear, extending the life of the tool and reducing the need for costly repairs.

Signs of Wear and Common Issues

Knowing when a part may need attention is crucial for effective maintenance. Some common signs include unusual noise, vibrations, or decreased cutting efficiency. By paying attention to these indicators, users can identify parts that may require repair or replacement. Proactive care in these areas can prevent more serious problems from developing, ensuring the tool continues to perform at its best.

Understanding the Function of Each Part

Each element within a power tool has a specific role that contributes to its overall operation. Understanding how these components work individually and together is key to maintaining effective functionality. By recognizing the function of each mechanism, users can better troubleshoot problems, perform repairs, and ensure the tool performs optimally throughout its lifespan.

For example, the motor is the heart of the tool, providing the necessary energy to power its movements. The trigger controls the flow of energy, allowing the user to adjust power levels depending on the task. Meanwhile, the protective casing shields the internal elements from damage and ensures safety during operation. These and other components work in harmony to create a seamless experience for the user.