Hydraulic machinery plays a crucial role in many industries, providing the force needed to perform heavy lifting and complex movements. The functionality of these systems relies on a network of interconnected elements, each serving a unique purpose in the operation of the equipment.

These systems are made up of several key components, which work together to ensure smooth and efficient performance. Each component has a specific function that contributes to the overall efficiency, making it essential to understand their interactions and maintenance needs.

In this section, we will explore the main components of hydraulic equipment, their roles, and how they work in harmony to deliver optimal performance. Understanding these elements is vital for anyone looking to maintain, repair, or improve the efficiency of such systems.

Understanding Hydraulic Cylinder Components

Efficient machinery relies on an intricate arrangement of elements, each fulfilling its own specific task to ensure optimal performance. In systems designed to generate powerful force through fluid pressure, various components work together in harmony to achieve seamless motion. The proper understanding of these elements is essential for effective maintenance, repair, and overall system efficiency.

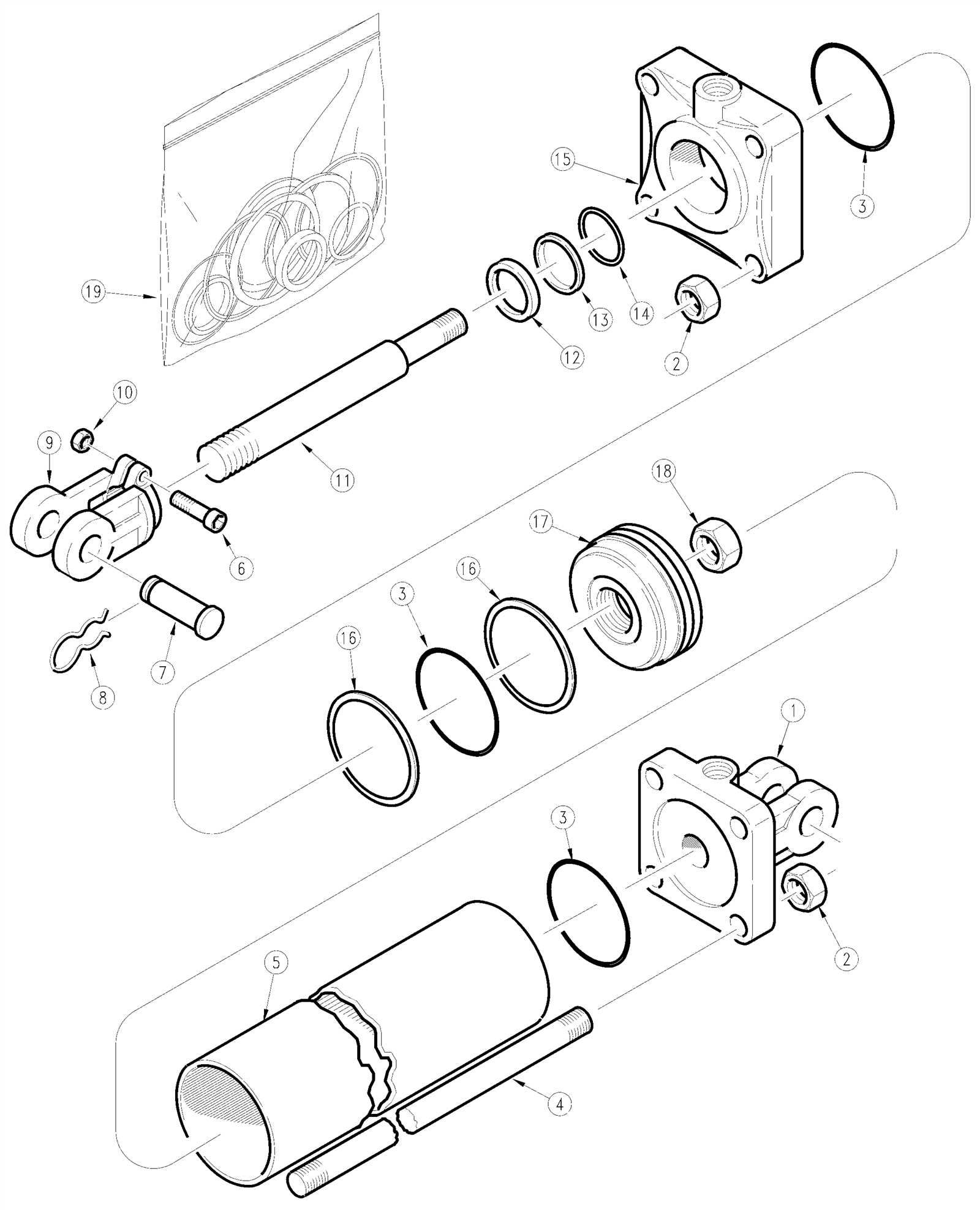

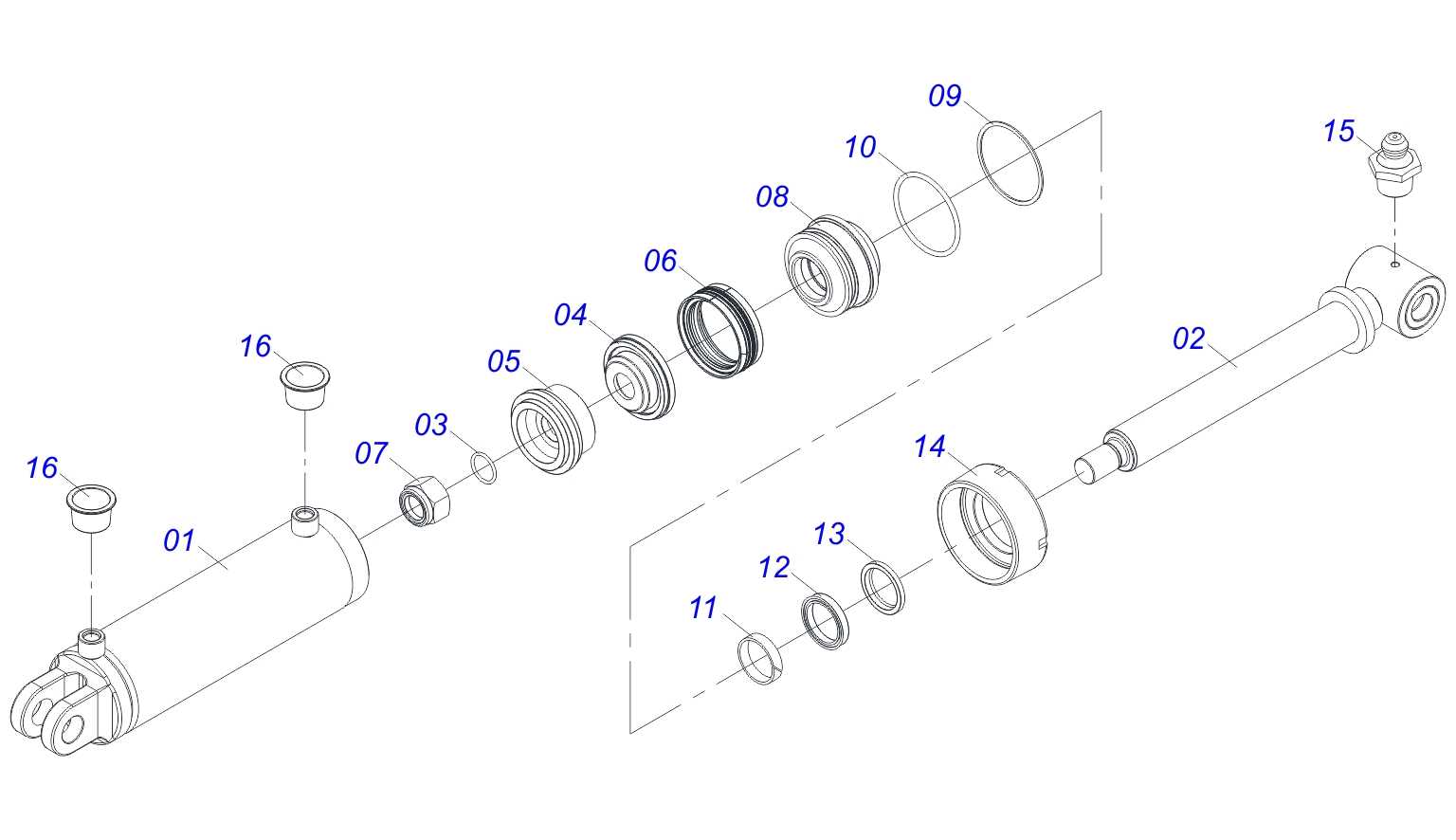

Main Functional Elements

The core components of such systems include the chamber, piston, and seals, each with its unique function. The chamber houses the working fluid and provides space for the piston to move. The piston itself is the moving part that converts fluid pressure into mechanical force, while the seals are responsible for maintaining pressure integrity and preventing fluid leakage. Together, these elements form the basis for any system that relies on controlled movement and force.

The Role of Pressure and Motion

Pressure within the system is key to its operation, with various parts designed to handle and direct this force. The interaction between the chamber and piston allows for a back-and-forth motion, enabling heavy machinery to perform tasks such as lifting or pushing. The smooth function of each element ensures that force is applied in the correct direction and with the necessary precision.

How Hydraulic Cylinders Work in Machines

Machines that rely on fluid pressure to generate force use a system of interconnected components to create movement. These systems convert energy from a pressurized fluid into mechanical work, allowing the equipment to perform tasks such as lifting, pushing, and positioning heavy loads. Understanding how these components interact is essential for optimizing machine efficiency and troubleshooting issues.

The pressurized fluid enters the working chamber of the mechanism, where it acts on a movable element. As the fluid fills the chamber, it pushes this element, creating linear motion. This movement is transferred to the rest of the machine, enabling the desired action. The ability to control the direction and amount of pressure applied is key to the precise control of the machine’s function.

Through careful design, these systems can be fine-tuned to handle varying amounts of pressure, ensuring that the equipment performs effectively under different conditions. The combination of precise fluid control, effective sealing, and durable moving parts ensures that the machine can work reliably for long periods without failure.

Key Parts of a Hydraulic Cylinder Diagram

Every fluid-powered system consists of several essential elements that work together to convert fluid pressure into mechanical movement. Understanding the core components of these systems helps in both their operation and maintenance. Each element serves a specific function that ensures smooth and effective performance, from generating force to controlling motion.

Main Elements for Fluid Control

The working chamber serves as the central space where the fluid is stored and directed. This area houses the moving element, which is responsible for translating the pressurized fluid into linear motion. Proper sealing around the edges of this chamber is crucial to prevent fluid leakage and maintain pressure, ensuring that the system functions without loss of power.

Movement and Pressure Regulation

One of the most important components is the piston, which moves inside the chamber. As the fluid enters, it applies force to the piston, causing it to move back and forth. The rod, which is connected to the piston, transfers this motion to the external mechanism, allowing it to perform work such as lifting or pushing. The pressure is carefully controlled through the use of various valves and seals that ensure movement happens smoothly and at the correct force.