When it comes to efficient agricultural or gardening work, knowing the essential elements of a spraying tool is crucial. Each element plays a specific role in ensuring the device functions optimally, providing users with effective coverage and ease of use.

Every tool is designed with key components that contribute to its overall performance. Whether you are looking to replace a worn-out element or enhance the efficiency of the device, understanding how the different parts interact is important for achieving the best results.

By familiarizing yourself with the various segments, from the pump to the hose and nozzle, you can better maintain, repair, or upgrade the tool to meet specific needs. A well-functioning system depends on each element working in harmony, making it important to ensure all parts are properly understood and maintained.

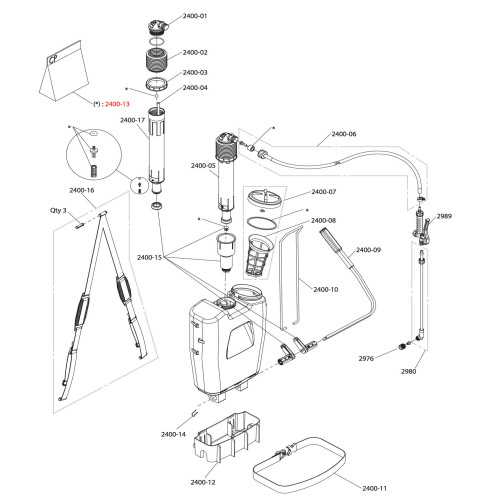

Key Components of a Spraying Device

Effective operation of a handheld spraying tool relies on several integral segments, each designed to perform a distinct function. From ensuring a steady flow of liquid to providing ease of application, every component plays a role in making the process more efficient and precise.

The primary elements include the container, which holds the solution, and the pump mechanism responsible for pressurizing the liquid. Another essential piece is the hose that transports the fluid to the nozzle, where it is dispersed in a controlled manner. Additionally, the handle allows for comfortable operation, and the pressure control system ensures the desired output.

Each of these components works together to ensure smooth and consistent operation, contributing to the overall effectiveness of the tool. Proper maintenance of each segment is crucial for achieving optimal results in various spraying tasks.

Exploring the Functionality of Each Part

Each segment of a spraying tool serves a specific function that contributes to its overall efficiency. Understanding how each piece works can greatly improve both the performance and longevity of the device. Let’s break down the role of these essential components.

- Container – This holds the liquid solution and allows for its secure transport. The capacity and material of the container affect how much liquid can be stored and how durable the unit will be under regular use.

- Pump Mechanism – Responsible for creating the pressure that pushes the solution through the system. The pump’s efficiency directly impacts the speed and consistency of application.

- Hose – The flexible tubing that carries the fluid from the container to the nozzle. Its length and material determine the ease of movement and the reliability of the fluid transfer.

- Nozzle – The part that disperses the liquid. It is designed to control the flow rate and pattern, allowing users to adjust spray output for different tasks.

- Pressure Control – Ensures the appropriate pressure is maintained throughout the application, preventing blockages and ensuring a uniform spray.

Each of these components is integral to the tool’s overall function, and regular maintenance can ensure optimal performance for longer periods. By understanding the role of each element, users can troubleshoot and enhance their device more effectively.

Step-by-Step Guide to Assembling the Device

Assembling a handheld application tool requires careful attention to each segment to ensure proper functionality. A precise approach during the setup can help you avoid potential issues and ensure smooth operation. Follow this guide to correctly assemble your device and achieve the best results.

Prepare the Components

Start by gathering all necessary elements, including the container, pump, hose, nozzle, and pressure control system. Lay them out in a clean area to ensure nothing is missed and everything is within reach for quick assembly.

Assemble the System

Begin by attaching the pump mechanism securely to the container. Ensure that it is tightly fitted to avoid any leaks. Then, connect the hose to the pump outlet, making sure the hose is free of kinks to ensure fluid flows smoothly. Once the hose is in place, connect the nozzle to the other end of the hose, adjusting it to your desired spray pattern.

Check the Connections: After assembling, check all connections for tightness and ensure that no leaks are present. Test the pressure control system to confirm the desired pressure is achieved.

Once all components are assembled and tested, your device is ready for use. Regular checks and maintenance after each use will keep it in optimal condition for longer periods of time.

How to Maintain and Troubleshoot Components

Proper care and timely troubleshooting are essential for keeping your application tool running smoothly. Regular maintenance can extend its life and enhance its performance, while addressing issues as they arise ensures consistent operation. Below are common problems and solutions for maintaining the device.

| Problem | Cause | Solution |

|---|---|---|

| Weak spray flow | Clogged nozzle or low pressure | Clean the nozzle thoroughly and check the pressure control for proper function. |

| Leaks | Loose connections or damaged seals | Tighten all connections and replace any worn-out seals or O-rings. |

| Pumping difficulty | Blocked pump mechanism or air trapped in the system | Ensure the pump is free of debris and bleed the system to release air. |

| Inconsistent spray pattern | Dirty or damaged nozzle | Clean or replace the nozzle to restore a consistent spray output. |

By regularly inspecting and servicing these components, you can avoid common issues and maintain optimal performance. Keep track of any wear and tear, and perform necessary repairs promptly to ensure the tool continues to work effectively over time.

Choosing the Right Components for Your Device

Selecting the right elements for your handheld application tool is crucial to ensure both efficiency and durability. The choice of each segment, from the liquid container to the nozzle, can significantly affect the performance and ease of use. Understanding what to look for when purchasing or replacing these components can help you make the most of your tool.

Consider factors such as material quality, compatibility with other elements, and the specific tasks for which the tool will be used. For instance, a larger container may be necessary for larger areas, while a fine mist nozzle might be more suitable for delicate applications. The durability of the pump mechanism is also key, as it will determine how well the device handles regular use over time.

By choosing high-quality components that meet your specific needs, you ensure that your tool operates smoothly and lasts longer. Take the time to assess the functionality of each part before making your decision to optimize the overall effectiveness of the device.