Every complex machine relies on a variety of essential elements that work together to achieve a specific function. These components, though diverse in nature, are carefully engineered to ensure smooth operation. Understanding how each part interacts with others can significantly improve our knowledge of how these systems perform efficiently.

Each element within the system plays a critical role in converting energy, maintaining stability, or ensuring longevity. Whether it’s the core mechanism that powers the operation or the smaller supporting parts, the entire structure is designed for precision and durability. The way they are integrated determines the efficiency of the overall system.

By exploring these crucial components and their functions, we can gain a deeper appreciation of how technology operates on a micro level. The internal makeup of these devices reveals how different sections are interdependent, each one performing its task to contribute to the overall performance.

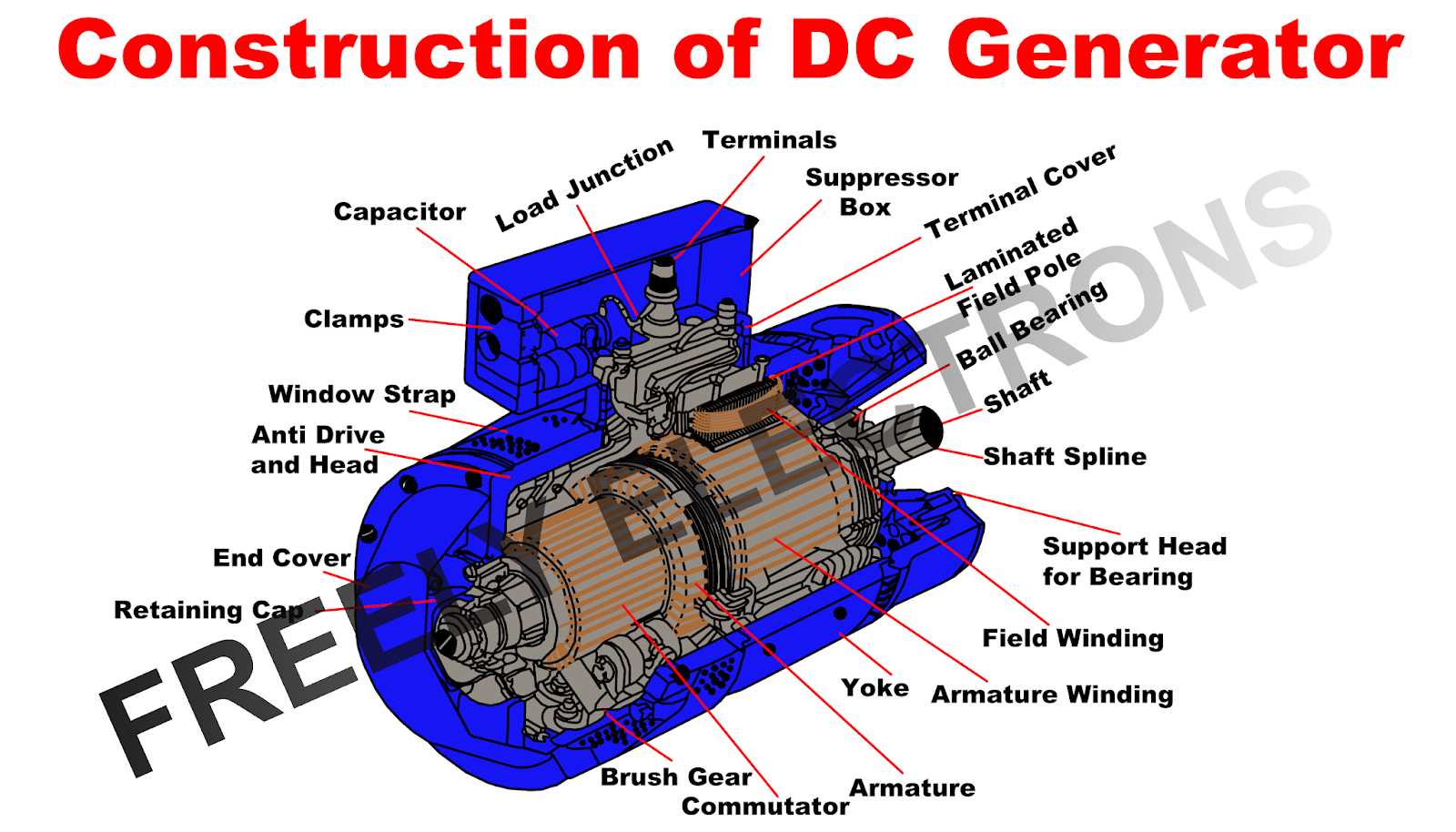

Generator Components and Their Functions

To understand how any power-producing machine works, it’s essential to examine its core elements and how they contribute to its operation. Each section is designed with a specific function that enhances the overall efficiency and performance. By analyzing these key components, we can uncover the inner workings and gain insight into how energy is harnessed and converted.

Main Functional Units

Each unit within the system serves a distinct role, working in tandem with others to ensure the machine operates smoothly. The primary elements include:

- Power Conversion Mechanism: This unit is responsible for transforming the input into usable energy.

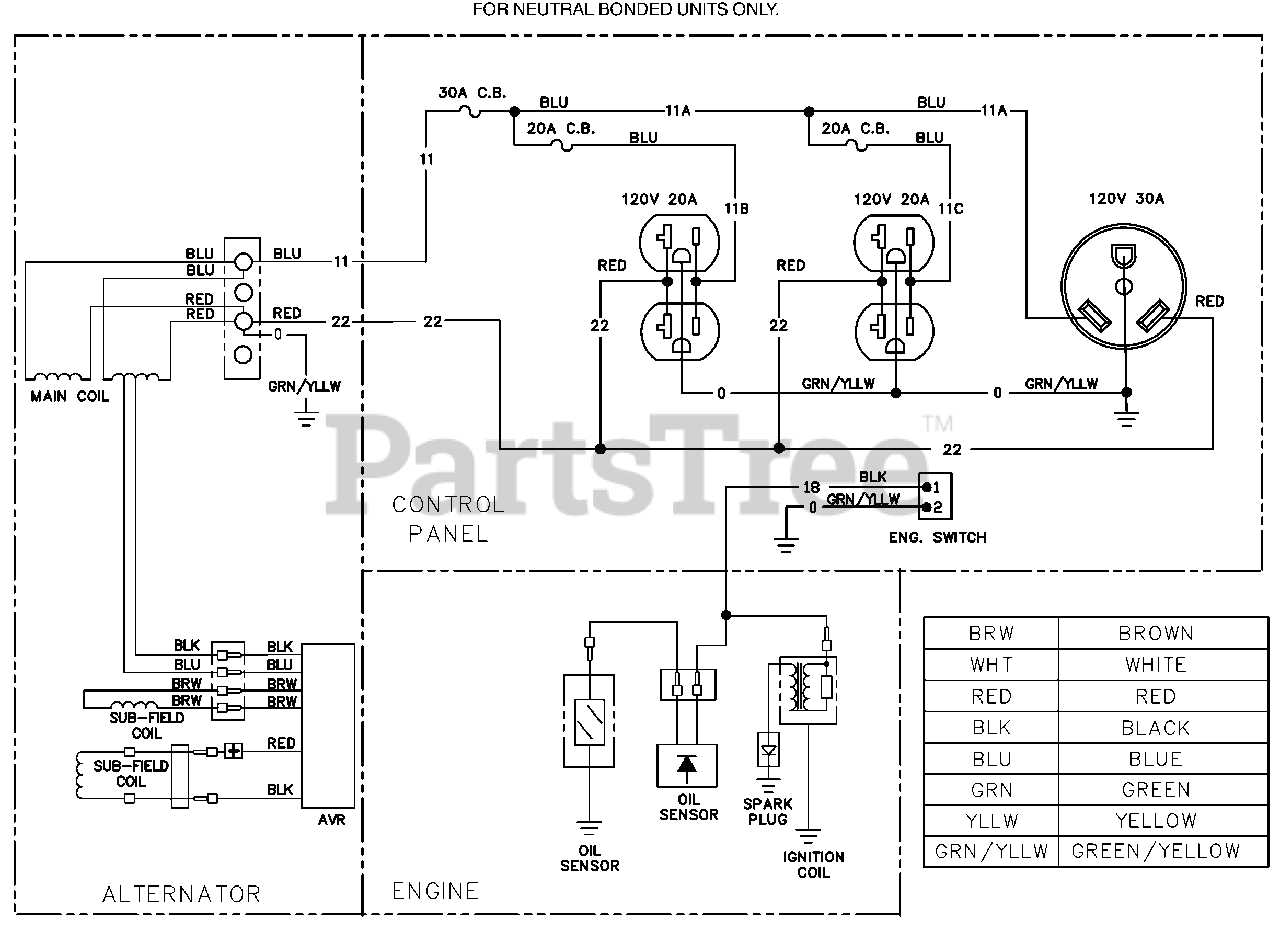

- Control Systems: Vital for maintaining stability and regulating the entire process, ensuring the machine operates at optimal levels.

- Energy Storage or Transfer: This section facilitates the storage or movement of the generated power to its intended destination.

Supporting Structures and Their Role

Along with the main units, smaller components assist in the seamless function of the device. These include:

- Cooling Systems: Essential for preventing overheating and maintaining optimal operating temperatures.

- Frame and Housing: Provides protection to the inner components and ensures structural integrity.

- Connection Points: Allows for proper attachment of external elements to the core units, ensuring synchronization across the system.

Each element, from the primary units to the smaller supporting components, is meticulously designed to perform its task, ensuring the overall functionality and longevity of the system.

How Different Parts Interact in a Generator

The efficiency of any energy-producing system depends on how its various components work together. These elements are interconnected in a way that each one supports the others to achieve a single goal. Understanding this interaction helps to appreciate the complexity behind the smooth operation of the machine.

Synchronization of Primary Units

The core mechanism that generates power relies on the coordination of several key units. Each section works in close unison to ensure a seamless flow of energy. For example:

- The conversion system generates the initial energy, which is then regulated by the control unit to maintain steady output.

- The energy storage or distribution components ensure that the generated energy is efficiently directed to where it is needed.

Supporting Units and Their Role in Performance

The smaller components are just as crucial in maintaining overall functionality. These supporting structures help maintain the primary systems by keeping them in optimal condition. For instance:

- The cooling system prevents overheating and ensures consistent output by regulating temperature.

- The housing and frame protect internal systems from external damage, which could disrupt the entire operation.

The interaction between all these elements is what allows the system to function reliably, with each part fulfilling its specific role while supporting others around it.

Essential Elements of Generator Design

The design of any power-producing machine is based on several fundamental elements that ensure both its efficiency and reliability. These components must be carefully considered during the design process to achieve the desired output and performance. Each section plays a key role in the overall operation and must be optimized for its specific function.

One of the most crucial aspects of design is the balance between power generation and stability. This involves selecting materials and structures that can withstand the forces involved while maintaining efficiency. Additionally, the system must be capable of managing heat and ensuring proper energy flow throughout the entire structure.

Furthermore, integrating the right control and monitoring systems is essential to ensure the machine runs smoothly. These systems help regulate power output, monitor performance, and prevent issues such as overheating or overload, contributing to the longevity of the equipment.

Structure and Operation of Key Parts

The internal structure of any energy-producing machine is designed to facilitate seamless energy conversion and distribution. Each critical section has a specific function, and together they work to ensure the overall efficiency of the system. Understanding the structure and operation of these elements is vital for ensuring optimal performance and durability.

Main Functional Units

The main functional units play an essential role in transforming raw energy into a usable form. Each unit within the structure is designed for a particular task, such as energy conversion or regulation. Below is a table highlighting some of the core components and their functions:

| Component | Function |

|---|---|

| Energy Conversion System | Transforms mechanical or thermal energy into electrical energy. |

| Control System | Regulates the flow of energy, ensuring consistent output. |

| Energy Distribution Mechanism | Transfers the generated power to the necessary systems or storage units. |

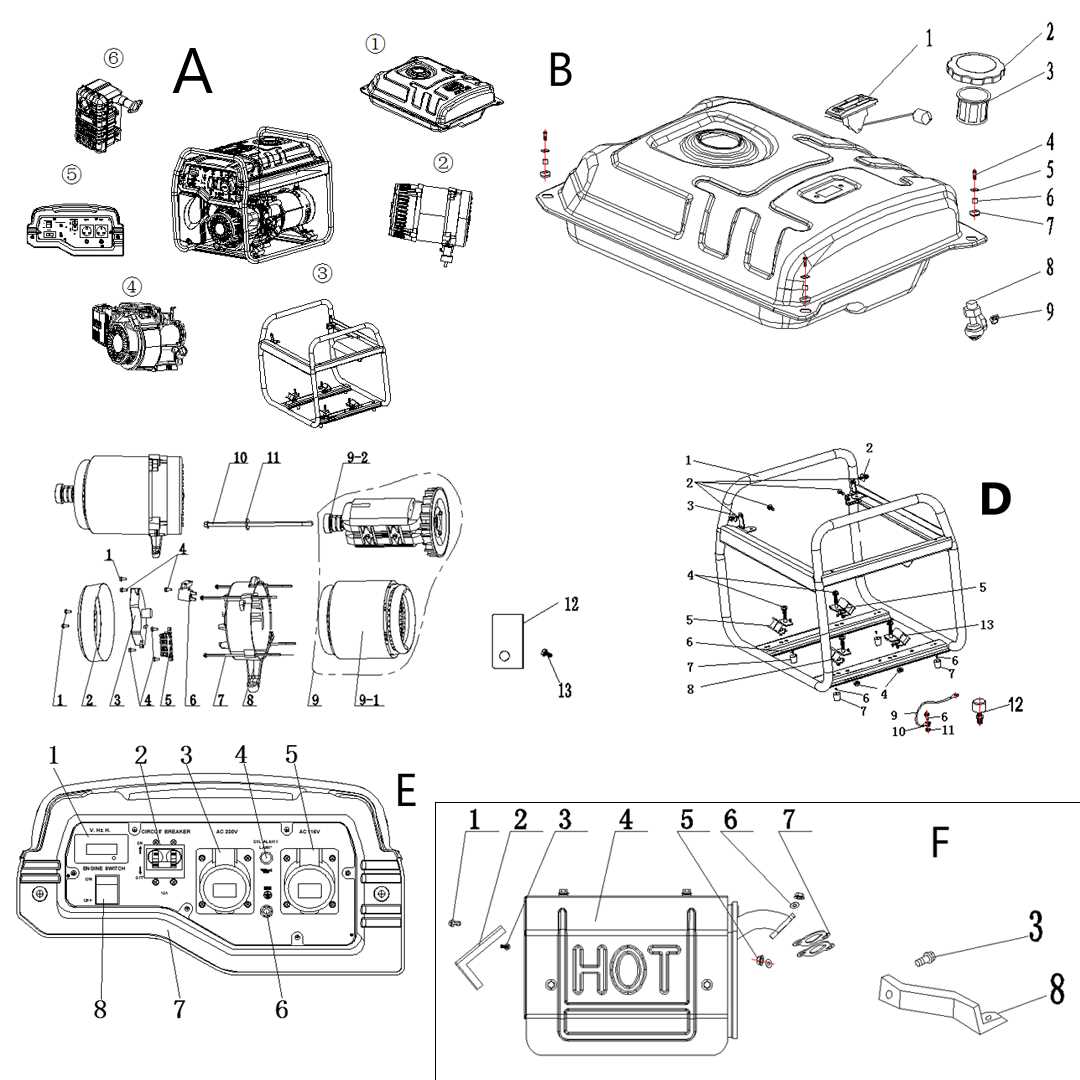

Supporting Structures

While the main units handle the energy conversion and regulation, the supporting elements ensure the system remains stable and efficient. These parts help maintain temperature, structural integrity, and the secure operation of the key components. Some of the supporting structures include:

- Cooling Mechanism: Prevents overheating by maintaining optimal temperature levels.

- Frame and Housing: Provides a protective structure for the internal components, reducing the risk of damage.

By understanding both the structure and operation of these critical sections, it becomes clear how each component contributes to the efficient functioning of the entire system.

Breaking Down a Generator’s Core Parts

Understanding the internal structure of a power-producing machine is crucial for comprehending how it functions efficiently. Each critical section serves a specific role that contributes to the overall performance, and breaking down these core elements allows for a deeper appreciation of their interaction. By analyzing these fundamental components, we gain insight into how energy is produced, regulated, and distributed.

Key Functional Units

The main components responsible for generating and managing power include:

- Energy Conversion Unit: This section is responsible for transforming input energy into electrical output, which is then used for various applications.

- Control System: A vital part that regulates the flow of electricity and ensures that power output is stable and within the desired limits.

- Distribution Mechanism: This component is essential for transferring the generated energy to the appropriate systems or storage locations.

Supportive Structures and Their Role

In addition to the core components, supportive elements are essential for maintaining smooth operation. These parts ensure that the system runs efficiently without overheating, physical damage, or malfunction:

- Cooling System: Keeps the entire system at optimal temperatures, preventing excessive heat buildup.

- Protective Housing: Provides structural protection to the internal components, shielding them from external harm and ensuring stability.

By examining these essential components, it becomes clear how each section interacts and contributes to the machine’s overall functionality.