The inner workings of automotive gear mechanisms are vital to the performance and smooth operation of vehicles. These systems play a crucial role in transferring power from the engine to the wheels, allowing for efficient movement and control. Understanding the components involved can help diagnose issues and improve the overall performance of the vehicle.

Every mechanism consists of a variety of interconnected elements that work in harmony to provide the desired motion. By studying these elements in detail, one can gain a clearer understanding of how each part contributes to the overall function. The precise arrangement of these components is essential for maintaining optimal functionality and durability.

Recognizing common problems and knowing how to identify wear and tear can save time and reduce repair costs. Whether you’re a mechanic or a car owner, having a solid grasp of the system’s structure and function is invaluable for keeping things running smoothly. Efficiency and reliability are the end goals, and this knowledge helps achieve them with confidence.

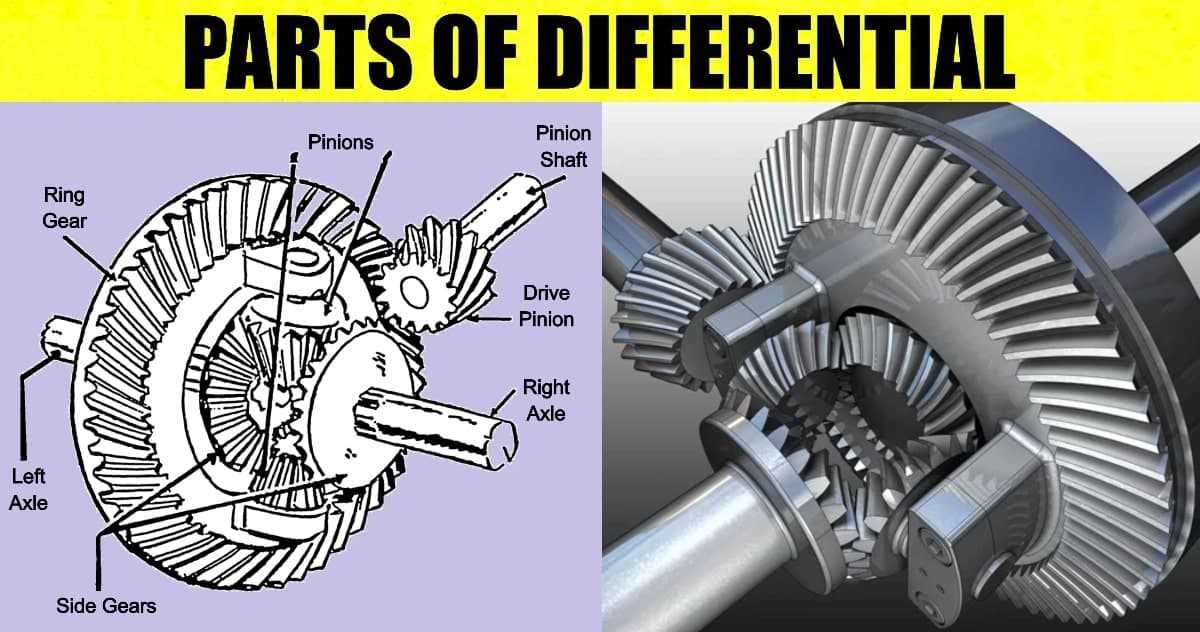

Key Components of a Differential

The mechanism responsible for transferring power to the wheels involves several crucial components that interact to ensure smooth operation. These elements must work together precisely to allow for controlled movement, especially when turning, and to manage the vehicle’s torque distribution effectively. Understanding these components helps in diagnosing issues and optimizing the system’s performance.

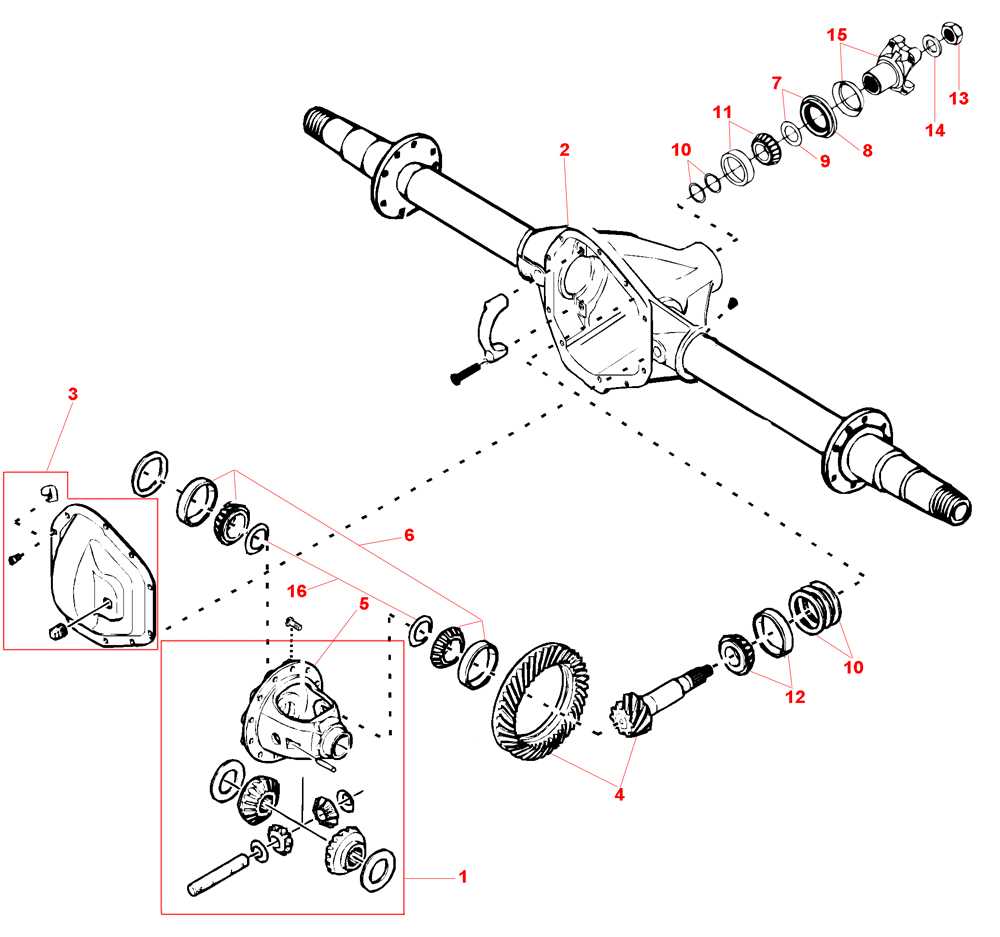

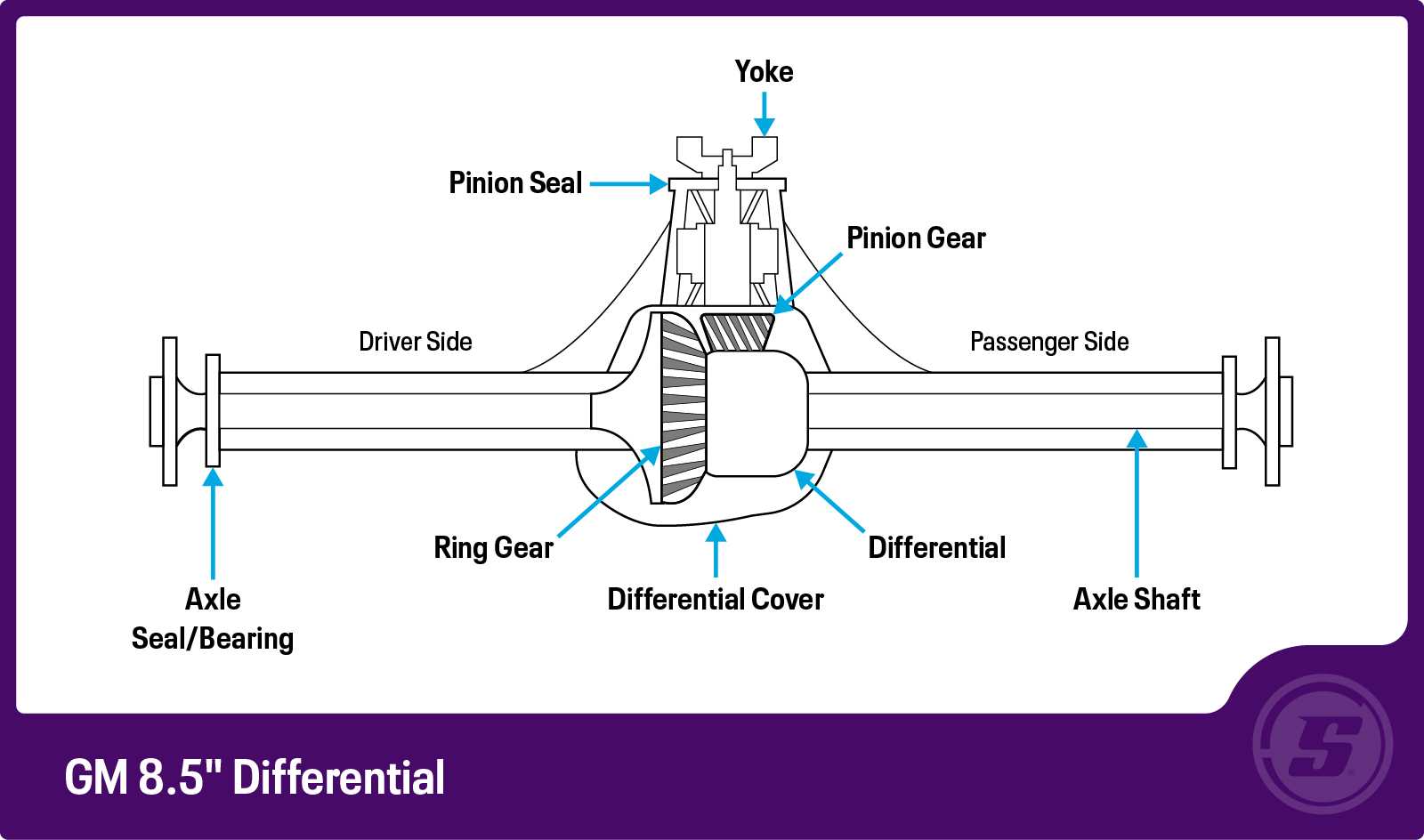

Housing and Casing

The housing serves as the protective outer shell that holds all the internal components in place. It ensures that all gears and moving parts remain properly aligned while also preventing contamination from dirt or debris. Made from durable materials, the casing plays an essential role in safeguarding the integrity of the entire system.

Gears and Axles

Inside the assembly, gears work to transmit power from the engine to the wheels. These gears are crucial for controlling the rotational speed and torque distribution between the drive shafts. Axles, connected to these gears, allow the wheels to rotate independently, which is particularly important when navigating turns. The precise alignment and condition of these components directly impact the vehicle’s handling and efficiency.

How Differential Components Work Together

The effectiveness of a vehicle’s drivetrain relies on the harmonious interaction of its internal components. These elements work in unison to transfer power efficiently while ensuring smooth navigation, especially during turns. Each part plays a vital role in maintaining balance, distributing torque, and allowing the wheels to rotate at different speeds when necessary.

Torque Distribution

The primary function of the system is to manage torque distribution. When a vehicle turns, the wheels on the inside of the curve rotate slower than those on the outside. The following components are involved in this process:

- Drive Shaft: Transfers power from the engine to the main system.

- Gears: Adjust the rotational speed and torque applied to each wheel.

- Axles: Allow the wheels to rotate independently, enabling efficient cornering.

Maintaining Stability and Control

The system also ensures stability during acceleration and deceleration by balancing power output. The interaction between gears, bearings, and the casing prevents excessive wear and tear, ensuring long-term reliability. This careful balance prevents power loss and minimizes stress on the system, allowing for a smoother driving experience.

Common Issues in Gear Systems

Like any mechanical system, the drivetrain components that transfer power to the wheels can experience wear and tear over time. When these parts malfunction, they can affect the vehicle’s handling, performance, and overall safety. Recognizing common problems early can help prevent more significant damage and costly repairs.

One of the most frequent issues is improper lubrication, which can cause excessive friction and lead to overheating. This often results in gear slippage, unusual noises, or even system failure. Another issue is worn-out seals, which can lead to leaks and contamination of the internal components. Additionally, improper alignment or broken bearings can lead to vibration, reduced efficiency, and uneven torque distribution.

Lastly, corrosion is a common problem in systems exposed to harsh weather conditions or off-road environments. Rust can weaken critical components, leading to costly repairs if not addressed. Timely maintenance and inspections are essential for keeping the system functioning at its best.