For efficient farming and soil cultivation, knowing the components of essential equipment is crucial. A thorough understanding of the various parts that make up agricultural machinery enhances productivity and simplifies repairs. By familiarizing yourself with these elements, you can ensure smoother operation and reduce the likelihood of malfunctions.

In this guide, we will explore the key components involved in such equipment, providing insights into their functions and importance. Knowing how each piece interacts with the others is fundamental for both maintenance and proper usage.

Familiarity with these components will help you make informed decisions, whether you’re operating the machine or performing troubleshooting tasks. A clear grasp of the different sections involved is essential for optimizing overall performance.

Key Components of a Disc Harrow

Understanding the essential elements of soil preparation machinery is crucial for achieving optimal performance. Each part plays a specific role in ensuring the equipment functions smoothly, from soil tilling to maintaining balance during operation. Knowing how these pieces interact allows for better efficiency in the field.

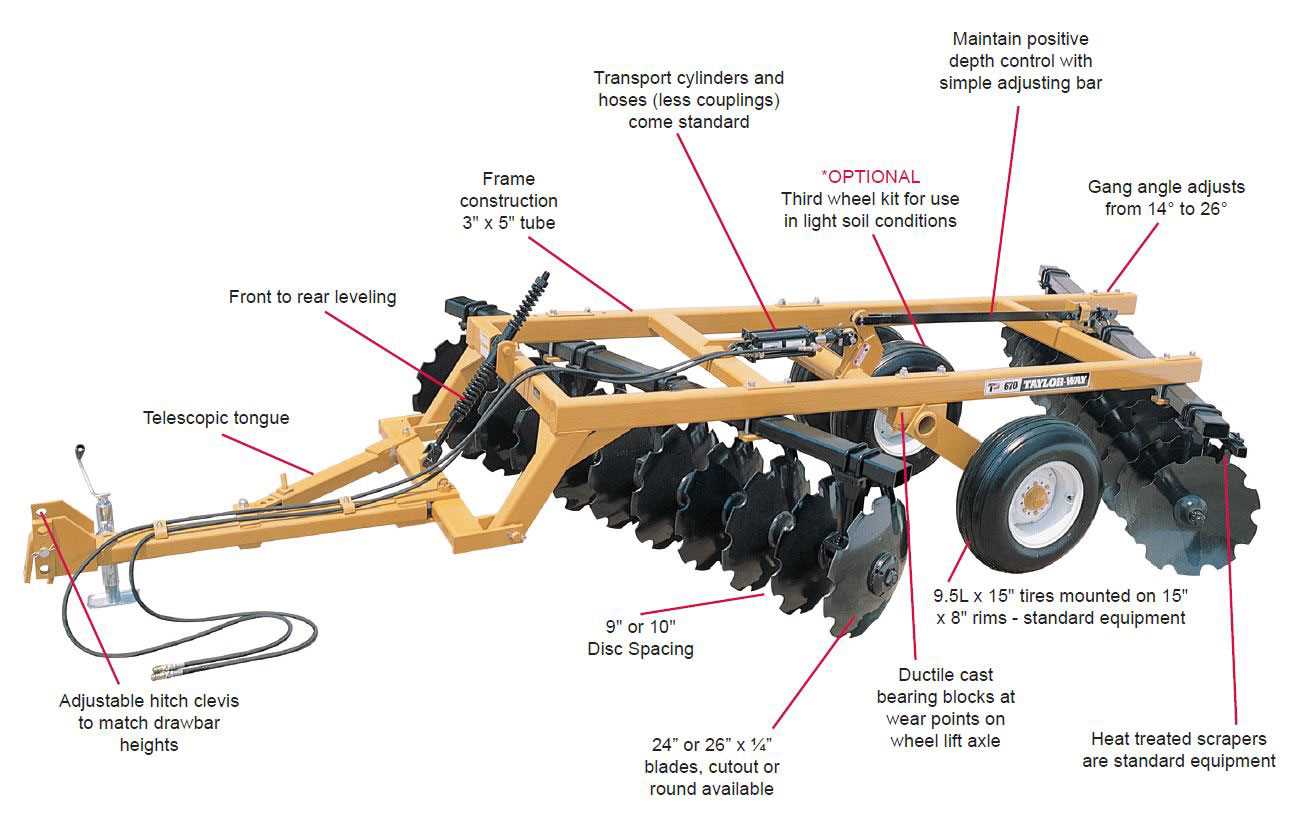

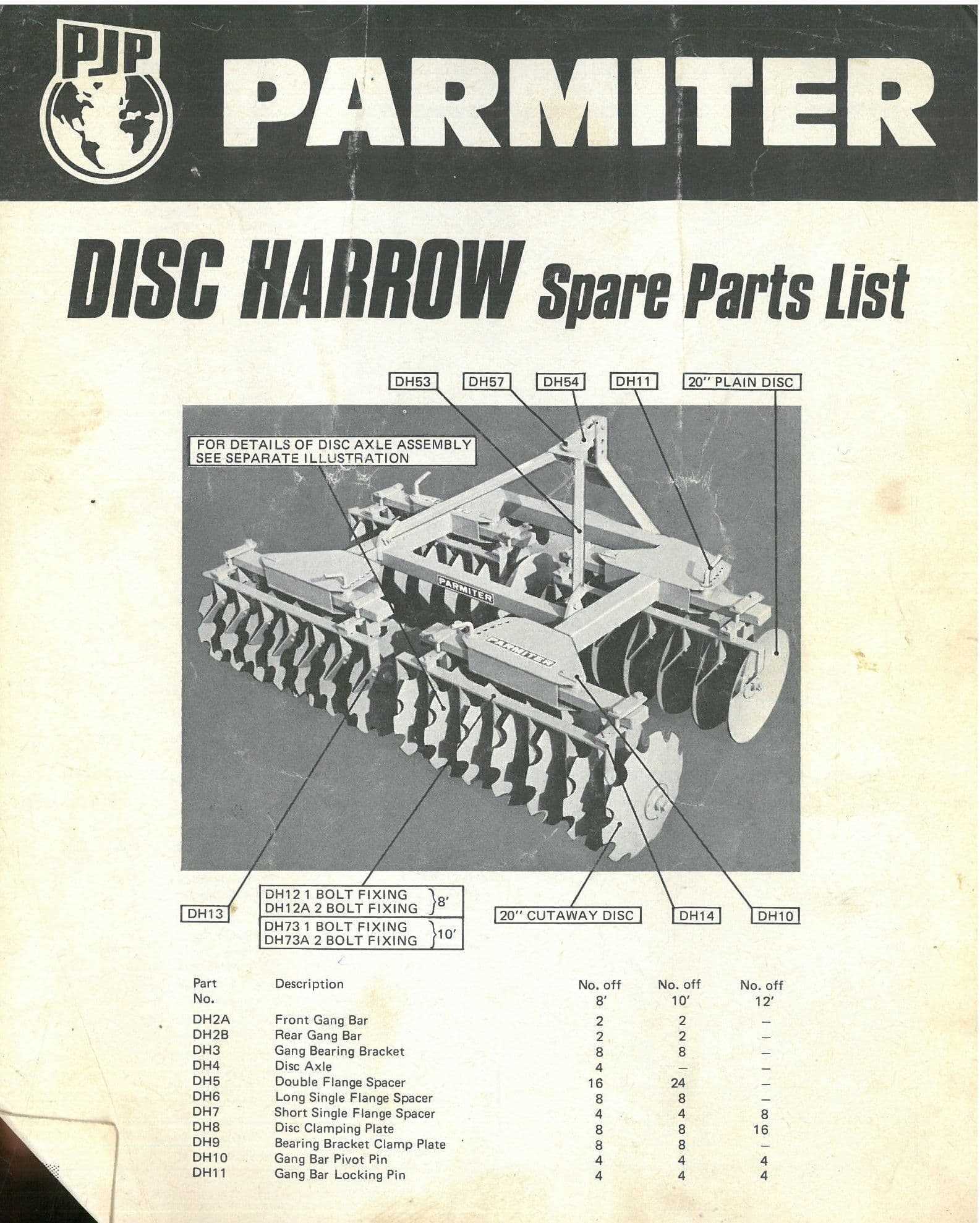

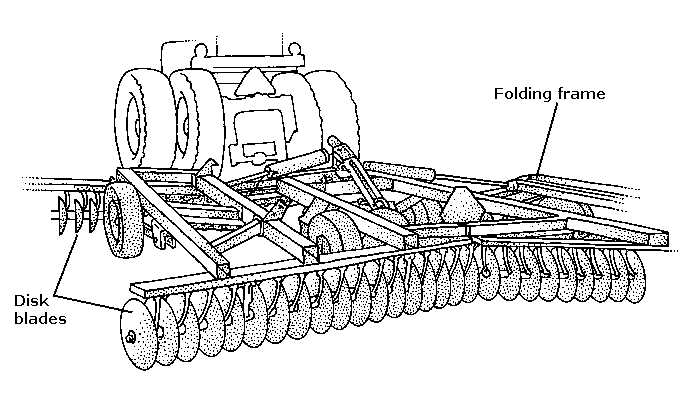

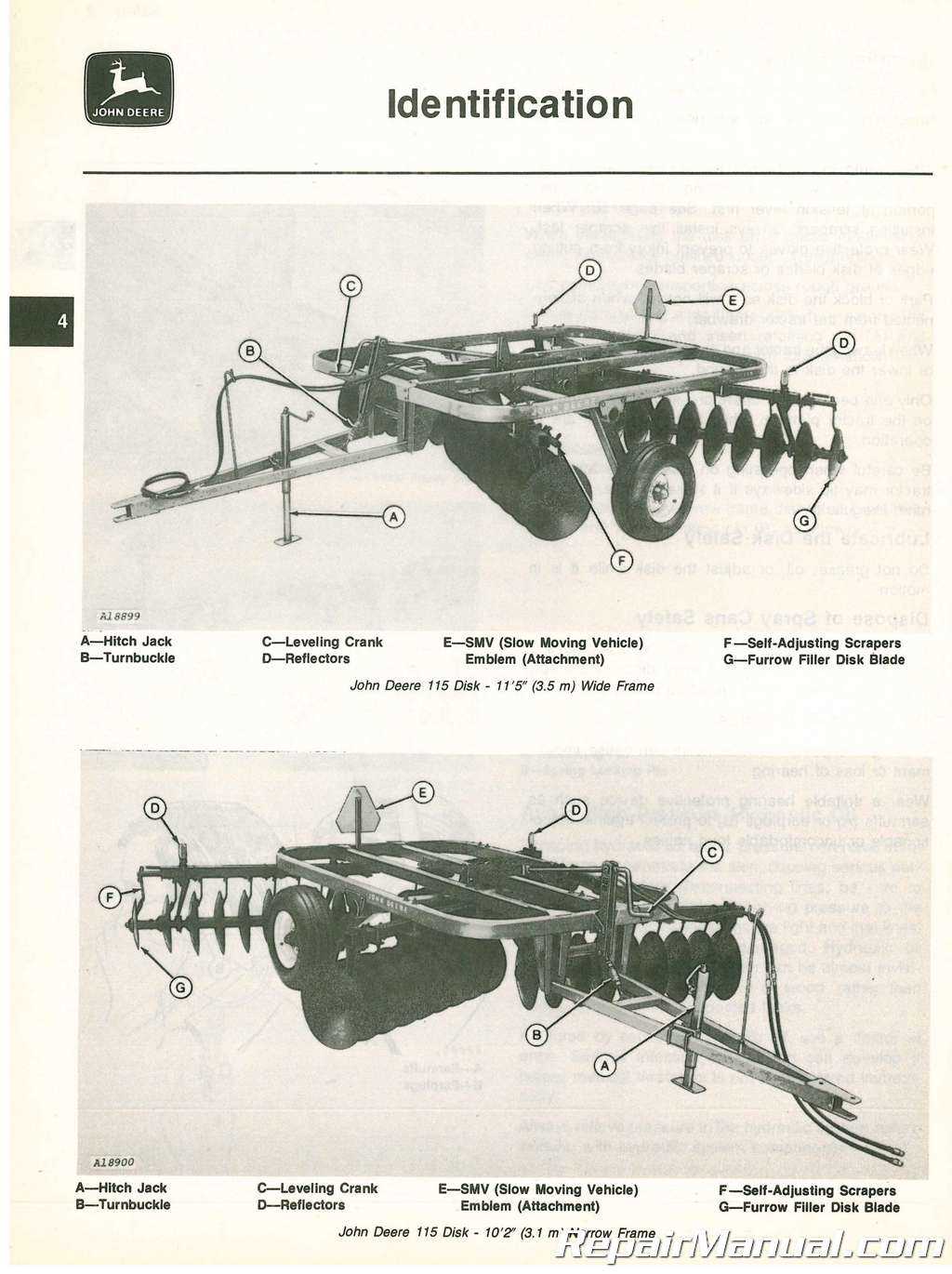

Among the most important components are the cutting edges, which are responsible for breaking up the soil, and the frame, which supports the structure. These work together to ensure effective soil movement and consistent depth control. Additionally, the wheels contribute to maneuverability and help maintain stability during operation.

The linkage system, which connects various parts of the machinery, ensures that the forces are distributed evenly for controlled movement. These components, along with the various attachments, ensure the equipment adapts to different soil types and conditions, making it an indispensable tool for farmers.

How to Identify Disc Harrow Parts

Recognizing the individual components of soil preparation machinery is essential for proper maintenance and troubleshooting. Identifying each element helps ensure that repairs or adjustments can be made efficiently, keeping the equipment in top working condition. Knowing the distinct features of each part allows for a better understanding of how they contribute to the overall function.

Examine the Structure and Function

The first step in identifying the elements is to examine the general structure of the equipment. Key components such as the frame, wheels, and attachment points are often easy to spot and are essential for supporting the other parts. Pay attention to the connection points where the soil-working components meet the main structure, as these are vital for operation.

Look for Wear Indicators

Another effective way to identify specific components is by inspecting wear patterns. Over time, the edges of soil-working elements show signs of wear, helping you pinpoint which part is most actively involved in the tilling process. Look for any parts that may be heavily worn or damaged, as they often signal the need for replacement or repair.

Benefits of Understanding Harrow Part Layout

Comprehending the arrangement and interaction of the various components in agricultural equipment leads to more effective use and enhanced performance. By familiarizing yourself with how the elements fit together, you can maximize productivity, reduce downtime, and ensure that the machine operates efficiently in different conditions.

Improved Maintenance and Repairs

Having a clear understanding of how the parts are organized helps in diagnosing issues quickly. Whether it’s adjusting a malfunctioning part or performing routine maintenance, knowing where each component fits ensures that you can take appropriate action without unnecessary delays. Proper maintenance extends the lifespan of the equipment and prevents costly breakdowns.

Optimized Performance and Efficiency

When you grasp how each component contributes to the overall functionality, it becomes easier to adjust settings for different soil conditions. Optimal configuration allows for better soil tilling, reduced energy consumption, and increased operational speed, making the equipment much more efficient. Understanding the layout ensures that you can adapt the machine for the best results every time.