Proper maintenance is essential for ensuring the long-term functionality of any machinery. Knowing the layout and components of your equipment helps prevent breakdowns and allows for quicker repairs. This section provides an in-depth look at how understanding your machine’s assembly can improve its efficiency and lifespan.

By familiarizing yourself with the structure and individual elements, you can spot potential issues early and tackle repairs before they become costly. A clear guide to the main components, their roles, and how they fit together will give you the confidence to manage upkeep effectively.

Whether you’re a seasoned professional or new to equipment care, a solid grasp of how everything works together ensures your machine remains in top condition for many years to come.

Understanding the Ditch Witch 1020 Components

Every piece of machinery is built from a series of interconnected elements, each serving a unique function to keep the entire system running smoothly. Understanding how these parts work together is essential for proper operation and efficient troubleshooting. By breaking down the core components, operators can ensure the machine functions at its best while avoiding unnecessary repairs.

The structure of this equipment consists of various assemblies, from power systems to mechanical elements. Each component has a specific role, whether it’s supporting movement, controlling energy flow, or providing stability during operation. Having a clear understanding of each part allows for better care and informed decisions when performing maintenance or repairs.

Familiarity with the layout and connections between these essential elements will help prevent common issues and ensure long-term reliability, whether for routine tasks or complex operations. The following sections will guide you through key components and their interactions within the machine’s overall framework.

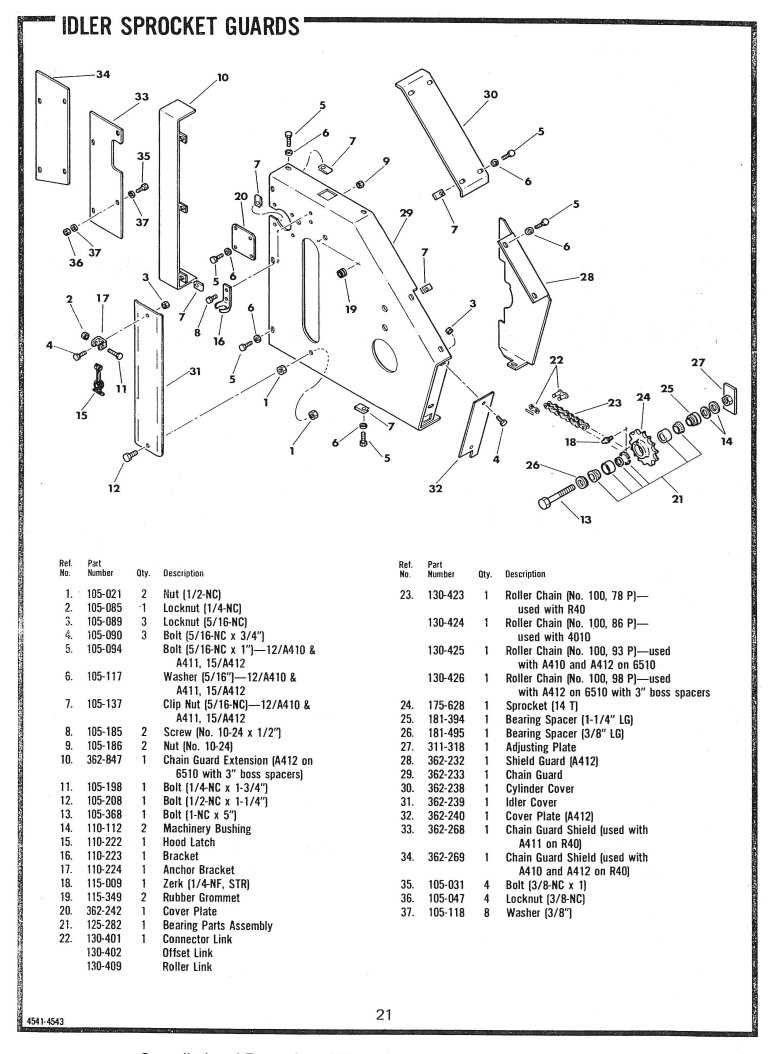

How to Read the Parts Diagram

Understanding how to interpret a machine’s visual guide is crucial for efficient maintenance and repairs. These visual representations provide a clear and detailed view of the equipment’s various components, allowing users to identify parts quickly and accurately. The key to reading these guides effectively is understanding the layout, labeling system, and how each component relates to others within the machine.

Typically, the diagram will display each element in a way that reflects its physical arrangement, offering both a top-down and side view of the machine’s construction. Symbols and labels are used to identify specific components, with numbers or letters corresponding to their unique identifiers. By following these markings, you can trace the relationship between parts and spot potential issues before they escalate.

When using the guide, it’s important to take note of the flow of energy, fluid, or movement between components. This helps in understanding how a malfunction in one part can affect the entire system. With practice, reading these illustrations will become an invaluable tool for anyone involved in maintaining or repairing equipment.

Common Ditch Witch 1020 Repairs

Regular use of heavy equipment often leads to wear and tear, resulting in the need for repairs. Identifying the most frequent issues that arise can help operators act quickly and minimize downtime. Understanding which components are most susceptible to failure ensures timely intervention and proper maintenance, keeping machinery running efficiently.

Hydraulic System Issues

The hydraulic system is a critical part of many machines, and problems with hydraulic fluid, pumps, or hoses can significantly affect performance. Common issues include fluid leaks, pump failures, or clogged filters. Regular checks of fluid levels and inspecting hoses for cracks or signs of wear can prevent unexpected breakdowns. Replacing filters and flushing the system periodically helps maintain smooth operation.

Engine and Transmission Problems

Engine and transmission malfunctions are another common area of concern. Overheating, poor lubrication, or fuel system issues can lead to poor engine performance. Routine inspections of the cooling system, air filters, and belts are essential to catch these problems early. Transmission issues, often related to fluid levels or seals, can also be avoided with regular checks and adjustments.

By addressing these common issues promptly, operators can extend the lifespan of their equipment and avoid more costly repairs. Regular maintenance and attention to detail are key to ensuring the continued efficiency of the machine.