When working with any machinery, knowing how each component fits together is crucial for maintaining optimal performance. Understanding the different elements that make up your tool allows for easier troubleshooting, repair, and efficient operation.

In this section, we will explore the internal structure of a common device, helping you identify key components. This knowledge will empower you to handle repairs and upkeep tasks with confidence, ensuring your equipment stays in top shape for longer periods.

By familiarizing yourself with the parts, you gain the ability to recognize problems early and make informed decisions about maintenance or replacements. Having a clear understanding of the system is the first step toward keeping your device running smoothly and efficiently.

Understanding the Dr Leaf Vac Components

Having a deep knowledge of the individual elements within a mechanical device allows users to troubleshoot and maintain their equipment more effectively. Each component plays a specific role in ensuring smooth operation, and recognizing how they interact is essential for long-term functionality.

When examining the internal structure, focus on the various key components that contribute to the machine’s performance. These elements work together to provide a seamless user experience, whether you’re using it for heavy-duty tasks or regular maintenance. Understanding their design and function will help you make better decisions when it comes to repairs and replacements.

It’s important to familiarize yourself with both major and minor components, as even small parts can have a significant impact on the overall efficiency. Recognizing wear and tear or potential issues early on can prevent more significant breakdowns and ensure that your device remains in working order.

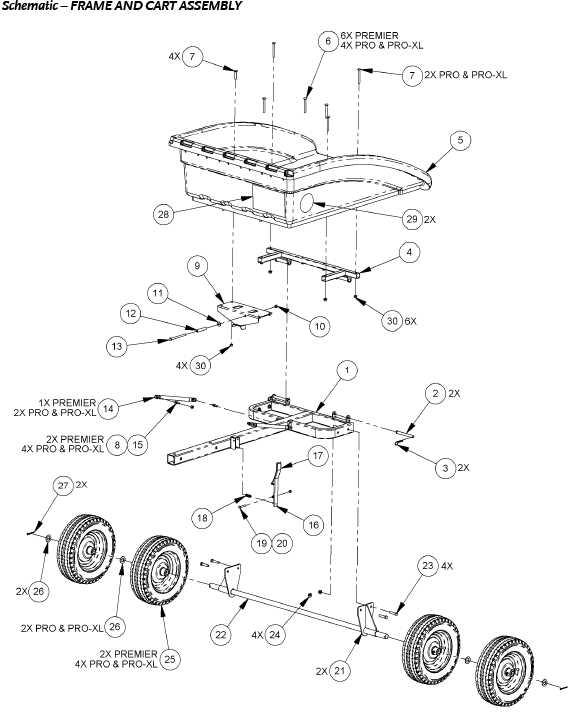

How to Read a Dr Leaf Vac Diagram

Interpreting the layout of any device’s internal structure is an essential skill for maintenance and repair. A clear visual representation of how different elements are arranged can help users quickly identify parts and understand their functions. This process makes troubleshooting simpler and allows for quicker resolutions when issues arise.

To effectively read a technical illustration, focus on understanding the various symbols and labels used. Each part is typically marked with specific identifiers, which guide you in recognizing their purpose within the overall system. Following the flow and connections depicted in the illustration can help you visualize how everything works together.

Additionally, it’s important to pay attention to the scale and orientation of the components in the illustration. A proper understanding of these details will help you match the visual representation to the actual configuration of your equipment, enabling more accurate repairs and adjustments.

Common Issues and Solutions for Dr Leaf Vac

As with any mechanical device, regular use can lead to wear and tear, resulting in performance issues. Identifying common problems early and addressing them promptly can prevent more serious breakdowns and extend the lifespan of your equipment. Understanding these typical malfunctions and their solutions is crucial for keeping your tool in good working order.

One of the most frequent issues users face is a decrease in suction power. This can often be traced to clogged airways, worn-out seals, or dirty filters. Cleaning or replacing these parts usually restores the tool’s efficiency. Another common problem is the motor overheating, which can happen if the device is overworked or blocked. Ensuring proper airflow and taking breaks between uses can prevent this from happening.

Occasionally, users may also experience problems with the power supply, such as flickering or complete loss of power. This can be caused by a faulty connection, damaged cords, or a malfunctioning switch. Inspecting the wiring and connections for any signs of damage and replacing the faulty parts will typically resolve the issue.