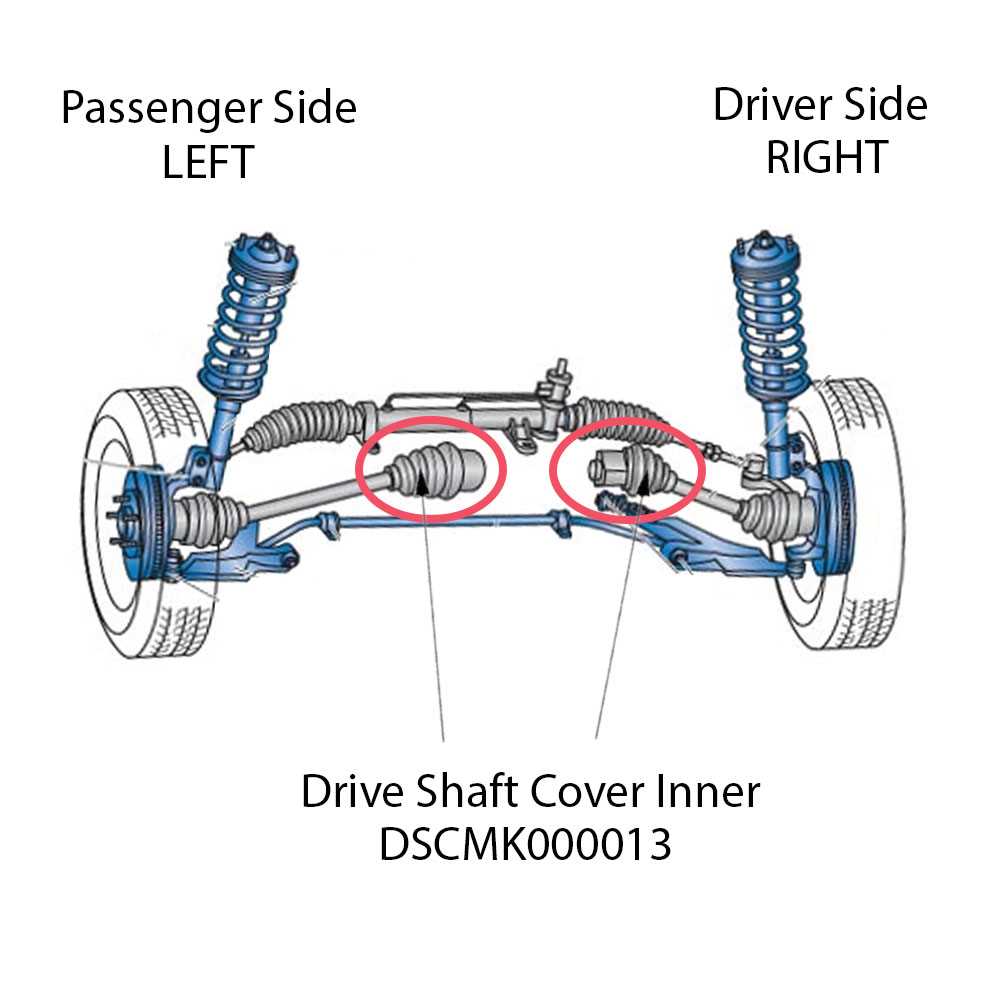

In any vehicle, the system responsible for transferring power from the engine to the wheels plays a crucial role in ensuring smooth operation. It consists of various elements working in harmony to deliver consistent performance. A detailed understanding of each component can help in better maintenance and troubleshooting.

Each element within this system serves a specific function, and knowing how they interact is essential for vehicle owners and mechanics alike. From the central assembly to smaller connecting components, each part must be carefully designed to handle the stress and torque exerted during operation.

Identifying and learning about these individual components helps ensure that any issues are addressed promptly, contributing to the longevity and efficiency of the entire system. This article breaks down the key features of each component, allowing for a clear understanding of their roles and how they work together seamlessly.

Understanding Drive Shaft Components

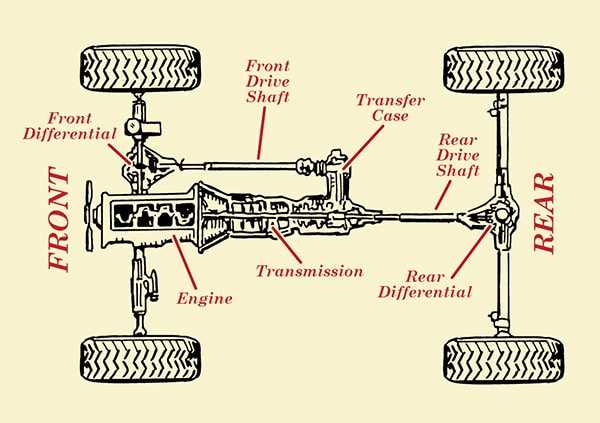

Within the power transmission system of a vehicle, various critical elements work together to transfer rotational energy from the engine to the wheels. These components must withstand considerable stress while ensuring that power flows seamlessly throughout the system. Understanding the function and interaction of each of these elements is essential for effective maintenance and repair.

The central component of this system is responsible for transmitting force, while smaller connections ensure smooth rotation and alignment. Each of these pieces plays a vital role in maintaining the integrity of the entire setup, and without them functioning properly, the entire system may fail to perform efficiently.

By examining the individual elements that make up this complex mechanism, it’s easier to recognize their importance and the potential issues that might arise if any one of them is damaged or misaligned. A clear understanding of these components helps in diagnosing problems and performing timely repairs.

Key Parts of the Drive Shaft System

The mechanism that transfers energy from the engine to the wheels consists of several interconnected components, each with a vital role. Understanding these elements is essential for proper maintenance and to ensure that the system operates efficiently. Below are the key components that make up this critical system.

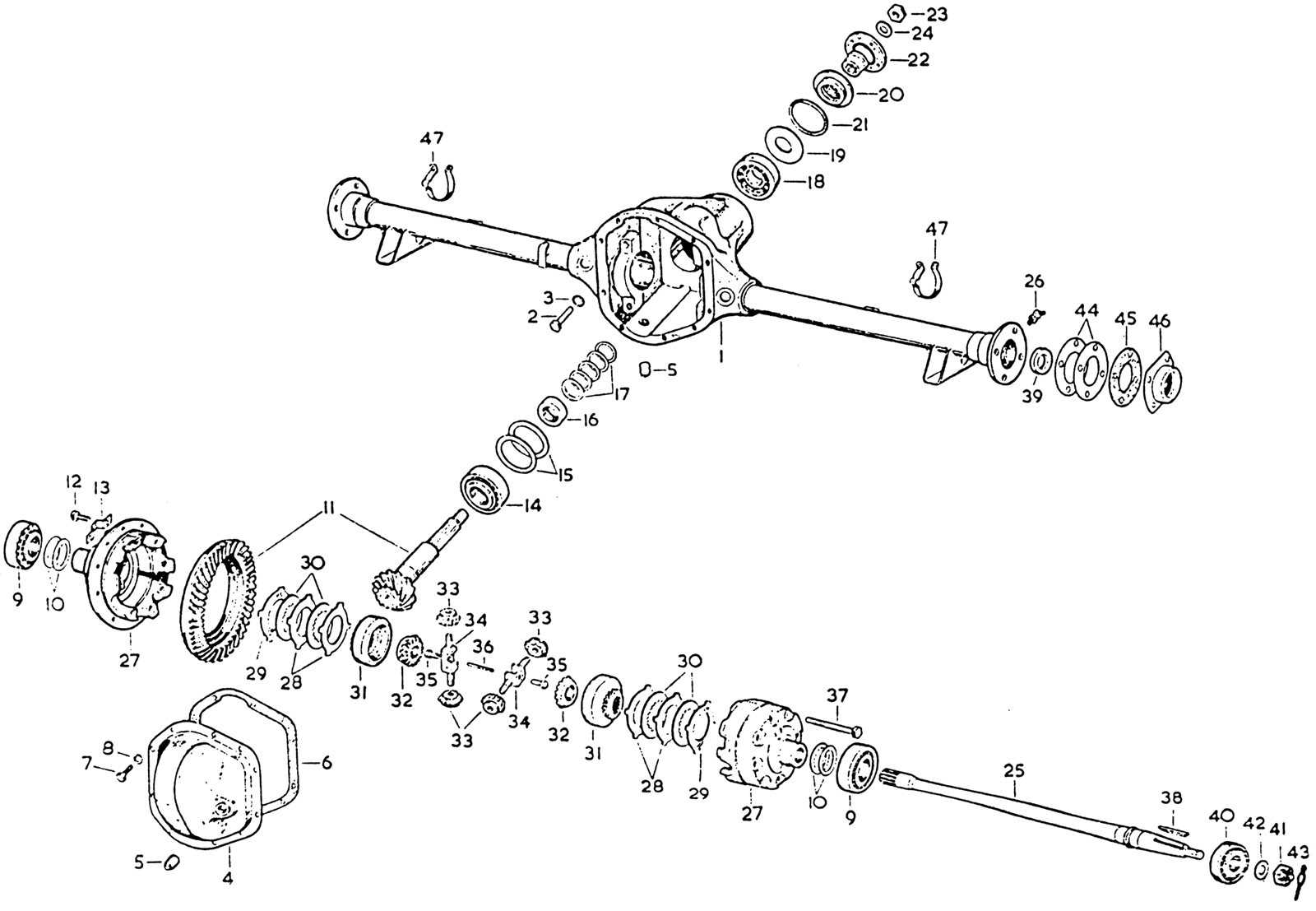

Primary Components

- Central Assembly: This is the core element responsible for transmitting rotational force.

- Universal Joints: These flexible joints allow for the movement and transfer of torque between the components.

- Couplings: Used to connect various sections of the system, ensuring smooth operation and alignment.

Supporting Elements

- Bearings: These reduce friction between moving parts, ensuring smooth rotation.

- Support Brackets: They help secure the components in place, preventing misalignment and damage.

- Flanges: These parts are used to attach different sections of the system, creating a stable connection.

How Drive Shaft Parts Work Together

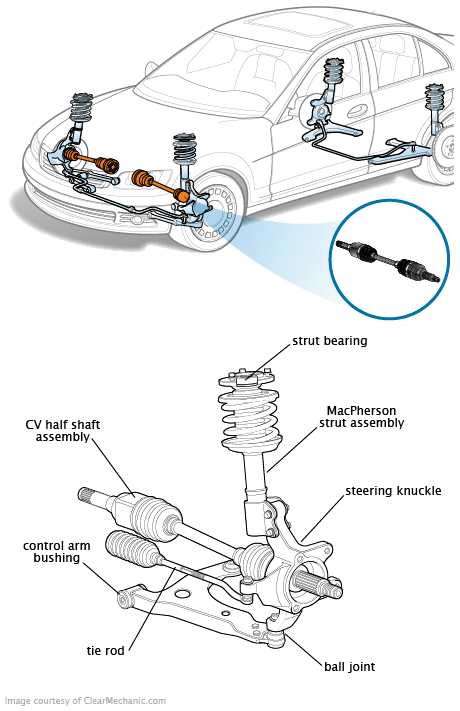

The components in the power transfer system are designed to work in unison, ensuring that energy flows smoothly from the engine to the wheels. Each piece has a specific function, but their combined efforts are what make the system efficient and reliable. Understanding how these elements interact is crucial for maintaining proper vehicle operation.

Coordinated Motion

When the engine generates rotational power, the central assembly begins to transmit that force through connected sections. Universal joints and couplings play a key role in allowing these sections to remain aligned and move smoothly even as the vehicle’s position changes. The movement of one element triggers the rotation of others, creating a continuous cycle of energy transfer.

Maintaining Stability and Alignment

Bearings and support brackets help maintain stability, preventing misalignment that could lead to excessive wear or system failure. Flanges create secure connections, ensuring that no component is left out of place as the entire system works together. Proper synchronization of all parts prevents friction, damage, and inefficient power transfer.