When your vacuum cleaner starts to show signs of wear or stops working efficiently, it’s important to understand its internal structure. Knowing how each component works together can help you identify issues quickly and even make repairs on your own. Proper maintenance ensures the longevity of the machine, and in some cases, replacing specific parts can restore its full functionality.

In this guide, we will explore the key elements of a popular vacuum cleaner model. From motor sections to filtration systems, each part plays a crucial role in overall performance. By familiarizing yourself with these components, you can confidently tackle repairs and keep your device running smoothly for years.

Understanding Dyson DC18 Parts Layout

Every vacuum cleaner is made up of several distinct components that work together to ensure optimal performance. These individual elements are carefully designed to fulfill specific functions, from suction to filtration, and even the overall structural integrity of the machine. Understanding how these components are organized within the device is crucial for proper maintenance and repair.

The layout of these elements follows a logical structure, with each part playing an essential role in the cleaning process. For example, the motor is usually at the core, surrounded by various attachments and filters designed to enhance performance. Knowing where each part is located and how it interacts with others can help identify issues quickly and allow for more efficient troubleshooting.

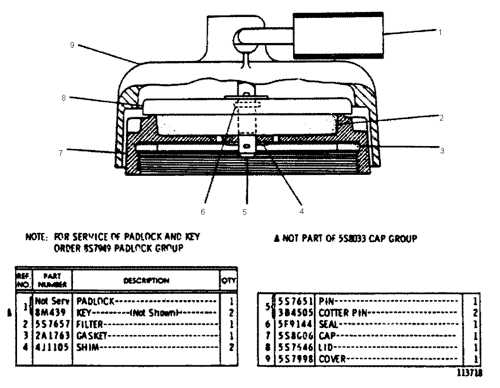

How to Identify Dyson DC18 Components

Identifying the different sections of a vacuum cleaner is essential for understanding how it functions and diagnosing potential problems. Each segment has its own unique shape and features, which makes it easier to spot when performing maintenance. Recognizing these elements helps in ensuring that every part is in good working condition and that repairs are done accurately.

Start by familiarizing yourself with the key parts, such as the motor housing, filter, and cyclone. These components are often positioned in specific areas and may require a certain method of disassembly for proper access. Pay attention to the size, shape, and materials of each piece, as these traits can guide you in identifying any worn-out or damaged sections. Once you know where each element is located, repairs or replacements become much more straightforward.

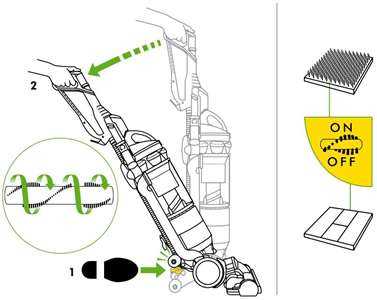

Steps to Replace Dyson DC18 Parts

Replacing faulty components in your vacuum cleaner is a straightforward process when done correctly. The key is to follow a series of steps that ensure safety and accuracy. Knowing the exact procedure allows for quick and efficient replacement, restoring the device to full functionality.

Begin by unplugging the vacuum cleaner and preparing a clean workspace. Next, carefully disassemble the sections that need attention, using appropriate tools to avoid damaging any parts. Once the broken or worn-out element is exposed, remove it and replace it with the new one, making sure it fits securely. Afterward, reassemble the vacuum and test it to confirm that the repair was successful. Following these steps will help maintain the longevity and performance of your device.