When maintaining or repairing a vacuum cleaner, it’s essential to familiarize yourself with its key components. Knowing the function of each part can significantly improve efficiency and extend the life of your device. This guide will help you identify the essential pieces and understand their roles in the overall system.

Proper identification of individual components is the first step in ensuring your vacuum works optimally. Whether you’re troubleshooting a malfunction or performing routine maintenance, recognizing each part’s function will make the process easier.

Replacing faulty parts can often be a straightforward process, especially when you have a clear understanding of the layout and connection points. With the right approach, you can keep your vacuum performing at its best for years to come.

Understanding the Vacuum Cleaner Components

To keep a vacuum operating efficiently, it’s important to have a clear understanding of its internal structure and individual elements. Each piece serves a specific function, and recognizing their roles can aid in troubleshooting and maintenance. Whether you’re looking to repair or replace a malfunctioning component, knowing what each part does will make the task easier and more effective.

The Key Components Inside the Device

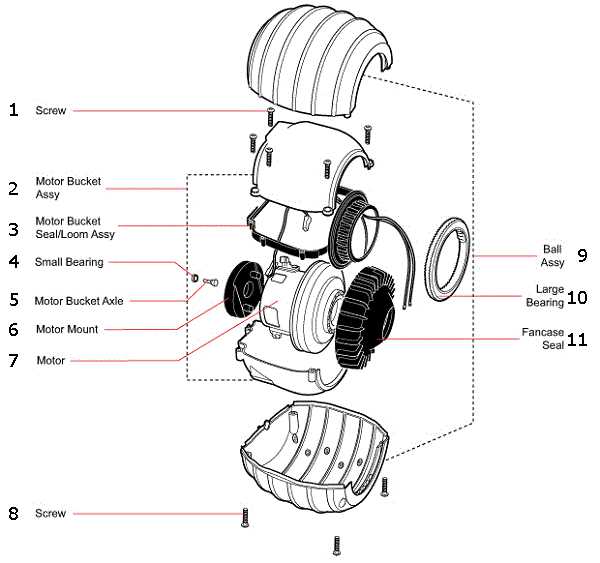

Most cleaning devices consist of a series of interconnected parts that work together to ensure smooth operation. These include the motor, filtration system, and rotating brush, among others. The motor provides the necessary power, while the filtration system ensures the air remains clean during operation. The rotating brush is essential for picking up debris, and understanding how these components interact helps in identifying potential issues.

Importance of Regular Maintenance

Regular maintenance of each element not only extends the life of your device but also ensures it performs optimally. Cleaning or replacing filters, checking the brush for wear, and ensuring all parts are properly secured can help avoid costly repairs in the future. Knowing when and how to service each part will make the process much simpler.

How to Identify Each Component

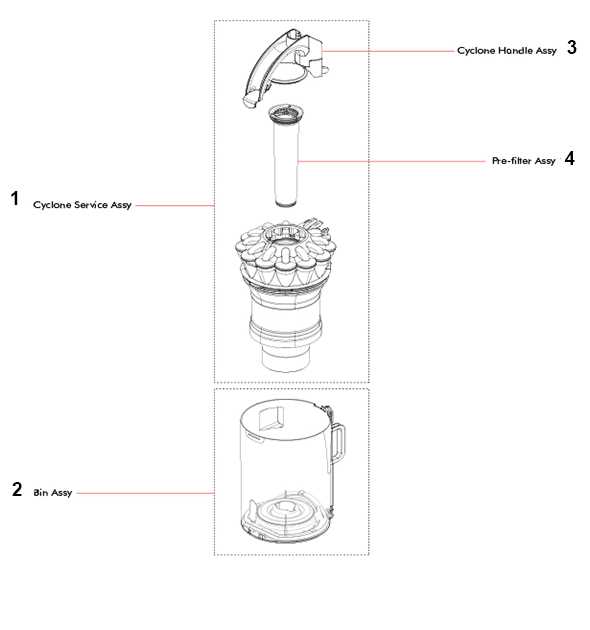

Recognizing the individual elements within a vacuum cleaner is essential for effective repair and maintenance. Knowing the function and appearance of each part makes it easier to diagnose issues and replace faulty pieces. By understanding how each component is structured and operates, you can quickly pinpoint problems and take appropriate action.

The first step in identification is familiarizing yourself with the main sections of the device, such as the motor assembly, filters, and brush. Each component is designed to serve a unique purpose, and understanding their locations within the machine will guide you during repairs. Keep an eye out for any signs of wear or damage, as these can help you determine whether a part needs attention.

Common Issues and Part Replacements

Over time, cleaning devices may experience wear and tear, leading to common issues that affect their performance. Identifying these problems early on can prevent further damage and help ensure your device continues to function at its best. Regular maintenance and timely replacements of certain components can extend the life of the equipment and keep it running smoothly.

Loss of suction is one of the most common issues faced by users. This can be caused by blockages in the hose or filter, or a malfunctioning motor. In such cases, checking for obstructions and replacing clogged filters can often resolve the problem. If the issue persists, further investigation into the motor or other internal components may be necessary.

Damaged brushes can also cause reduced cleaning efficiency. If the brushes become worn or tangled with debris, they may no longer rotate properly, affecting the vacuum’s ability to pick up dirt. Replacing the brush bar is a straightforward solution to restore the vacuum’s cleaning power.