Proper maintenance of any outdoor machinery relies heavily on understanding how its components work together. When it comes to garden cultivation equipment, knowing the layout and function of each individual element is essential for smooth operation and repairs. A comprehensive guide to these mechanisms can save time, reduce errors, and enhance the efficiency of your equipment.

Identifying key components and their roles ensures that you can troubleshoot and address issues swiftly. Whether it’s for routine maintenance or a more significant repair, understanding the inner workings of your machine can prevent unnecessary damage and extend its lifespan.

In this article, we’ll explore the basic structure of garden cultivators, providing a visual aid to help you identify the most crucial parts. We’ll also discuss common problems users encounter and offer solutions to keep your equipment in top condition for every gardening season.

Understanding Garden Cultivator Components

To effectively use and maintain any gardening equipment, it is crucial to understand how its internal mechanisms work together. The machine relies on a variety of essential elements that perform specific functions, from the engine to the rotating blades. Each component must be in top condition for the equipment to function properly and efficiently.

Key Elements and Their Functions

At the core of most garden machinery lies the engine, which powers the entire system. Coupled with it are various gears and shafts that transmit power to the rotating implements. These components work together to break up soil, making the cultivation process smoother and more efficient. The handles and control systems allow the user to adjust settings and ensure the machine operates at the right speed and depth for the task at hand.

Maintenance and Care

Regular inspection and care of each component are essential for optimal performance. Parts like the gear system, engine, and rotating blades require periodic checks for wear and tear. Simple maintenance tasks such as lubrication, cleaning, and tightening of bolts can prolong the lifespan of your equipment. Understanding the layout of the individual components will make it easier to identify problems and perform necessary repairs when required.

How to Read the Parts Diagram

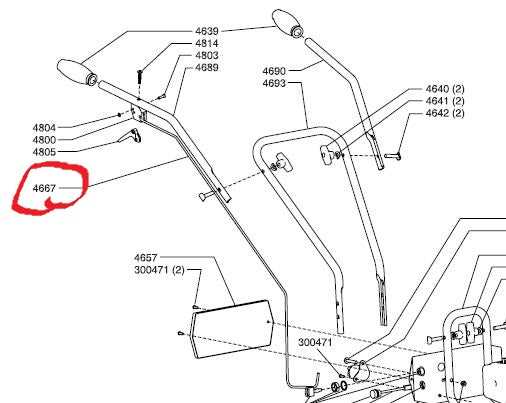

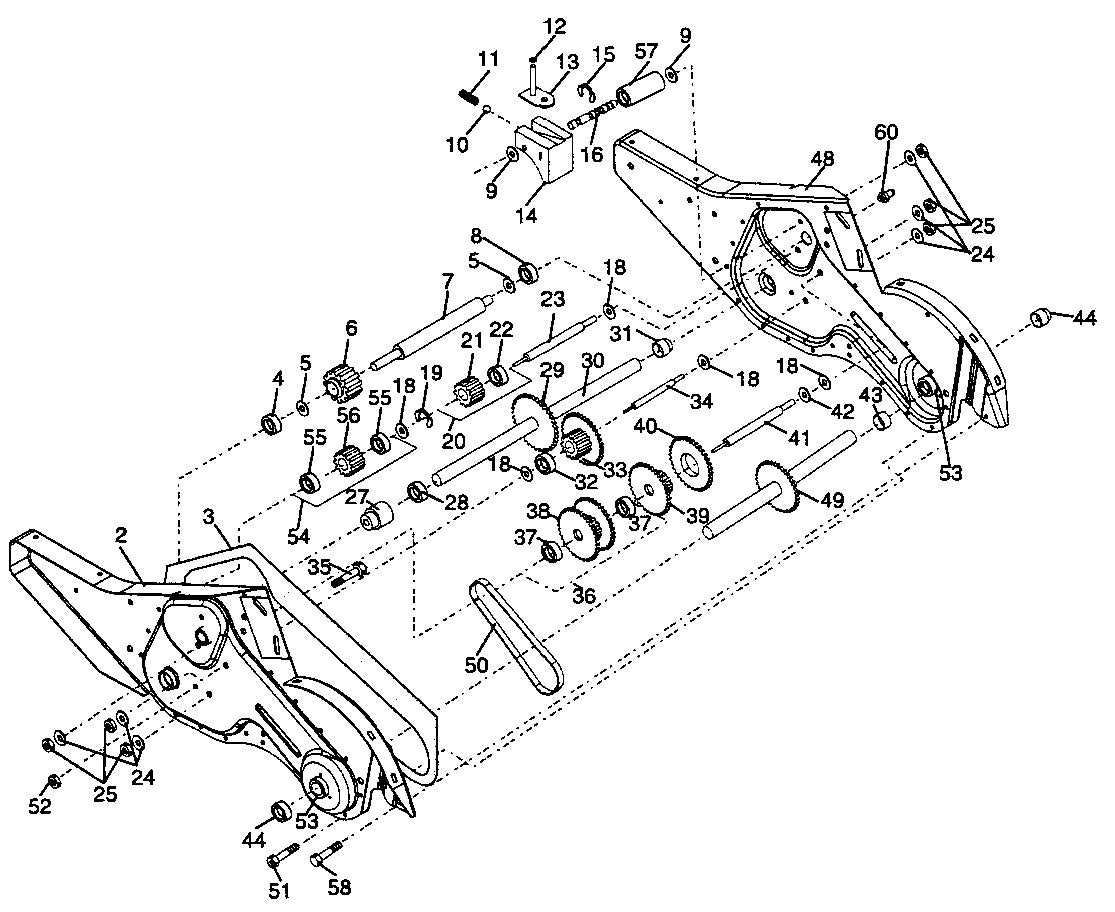

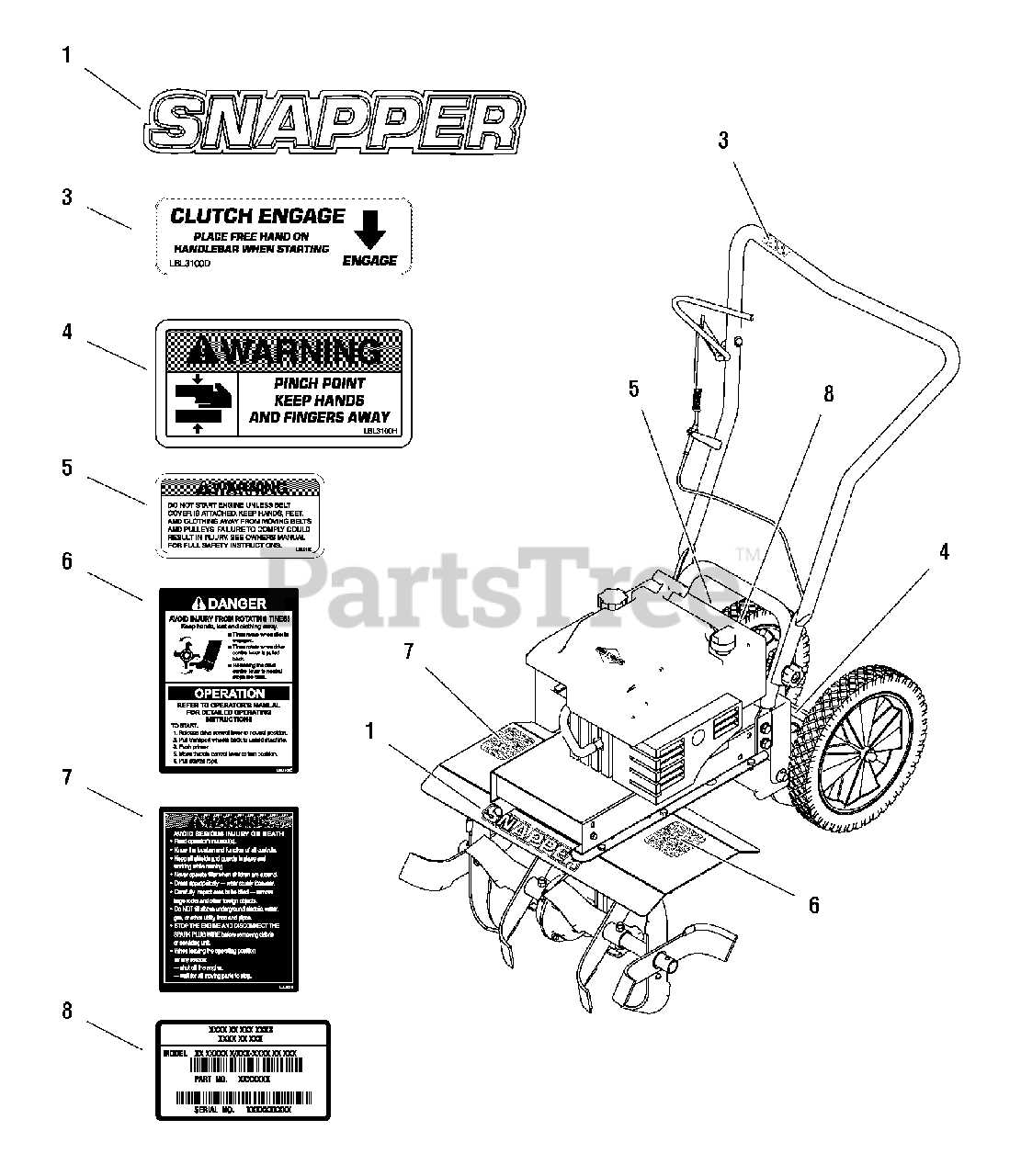

Understanding a machine’s internal layout is crucial when it comes to repairs and maintenance. A well-structured illustration can simplify identifying each component and its connection to others. Learning to interpret such visuals allows for quicker troubleshooting and more efficient part replacement, ultimately saving time and reducing errors.

The key to reading a system map is to start by recognizing the labels associated with each part. These often include both numbers and descriptive titles that correspond to specific components. The diagram will typically show the machinery from various angles, highlighting critical areas like the engine, drive system, and rotating elements. Familiarizing yourself with these labels will make it easier to locate issues and identify the necessary replacements.

Next, it’s important to understand the flow of the system. Diagrams often show how parts interact with each other, demonstrating the direction of power transmission or mechanical movements. Recognizing these connections helps visualize how the machine operates as a whole. Whether you are looking to replace a single part or perform a more comprehensive repair, understanding the relationships between components will guide you through the process effectively.

Common Issues with Tiller Components

When using any garden cultivation equipment, several common problems can arise due to wear and tear on various mechanisms. Recognizing these issues early can help avoid costly repairs and ensure the equipment continues to perform at its best. Common issues often involve key components like the engine, rotating blades, or the transmission system.

One frequent problem is a malfunctioning engine, which may fail to start or run inefficiently. This can be caused by a number of factors, such as clogged fuel lines, a dirty air filter, or faulty spark plugs. Regular maintenance and cleaning of these components can prevent such issues from disrupting operation.

Another common issue involves the rotating implements, which may become dull or damaged over time. When these parts no longer perform effectively, they can lead to uneven soil breaking or complete failure to function. Inspecting and replacing the blades or tines when necessary is crucial to maintaining smooth operation. Additionally, parts of the drive system may wear out, causing slipping or inconsistent power delivery. Ensuring these elements are well-lubricated and free of debris can help mitigate such problems.