Proper maintenance of outdoor machinery requires a clear understanding of its internal mechanisms. This knowledge helps users identify potential issues and perform repairs efficiently, ensuring the longevity of their equipment. By familiarizing oneself with the layout and function of each component, one can address problems more effectively and make informed decisions when parts need replacement.

Each machine consists of multiple elements working in harmony to ensure optimal performance. Visual aids and manuals serve as valuable tools for those unfamiliar with the intricate details. They allow users to pinpoint the exact location of components and understand their interrelationship. Knowing where each piece fits into the bigger picture can simplify troubleshooting and enhance repair efficiency.

Maintaining these devices is crucial for achieving the best results. With the right knowledge and tools, users can extend the lifespan of their machines and avoid unnecessary expenses. Understanding the layout of the equipment makes it easier to handle breakdowns and avoid future issues, offering peace of mind for owners.

Understanding Lawn Equipment Components

The efficient operation of outdoor machinery relies on a combination of various internal elements working together. Each component plays a specific role, contributing to the overall functionality of the device. When users have a clear understanding of these elements, it becomes easier to identify issues, perform maintenance, and replace damaged components without hassle.

Key components such as the engine, fuel system, and air filtration are essential for the machine to function properly. Other parts like the housing, fan, and throttle controls work in conjunction to ensure smooth operation. Recognizing how these parts interact is crucial for troubleshooting and repair, as a problem with one part can often affect the entire system.

Knowing the function of each element helps in diagnosing problems efficiently. Whether it’s the ignition system or the exhaust components, understanding their roles ensures that repairs are done correctly and that the machine continues to perform at its best. This knowledge empowers users to maintain their equipment and extend its lifespan, reducing downtime and costly repairs.

How to Read the Parts Diagram

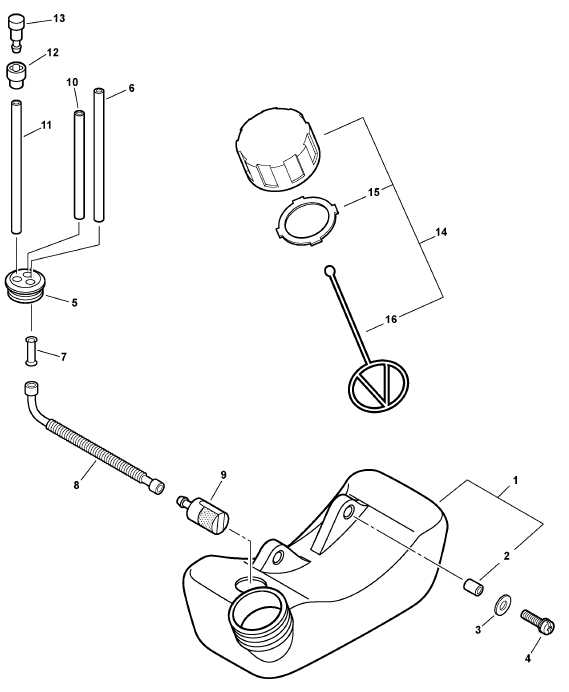

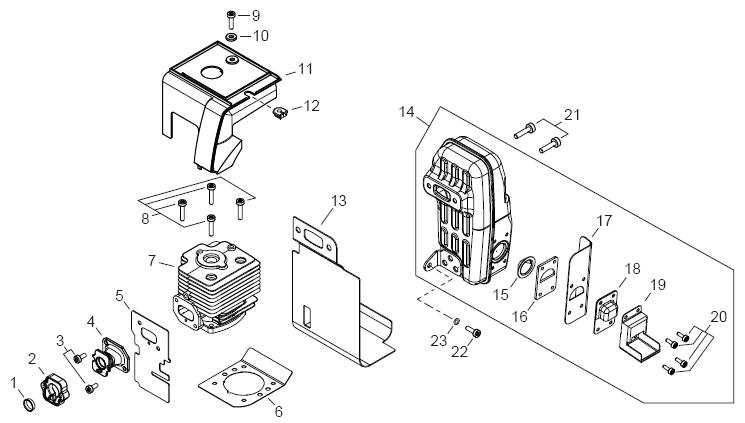

Understanding how to interpret the visual representation of the equipment’s internal components is key to performing effective maintenance. A well-organized schematic allows users to easily locate specific elements and understand their arrangement within the system. This visual guide simplifies the repair process by showing how each part fits and interacts with the others.

Identify Key Components

When examining a schematic, start by identifying the major components like the engine, fuel system, and airflow system. These are typically highlighted and labeled to make navigation easier. Familiarizing yourself with their locations can help you identify which area to focus on when troubleshooting or replacing a part.

Follow the Connections

Next, observe how the different elements are connected. Arrows, lines, and other markings will show the flow of air, fuel, and exhaust, which helps in understanding the system’s operation. Recognizing these connections is important for identifying potential issues and ensuring that all components are functioning correctly during reassembly.

Common Issues and Repairs for Lawn Equipment

Outdoor machinery, despite its durability, can encounter various problems over time. Understanding the most frequent issues and how to address them can help extend the lifespan of your equipment. Many common problems are related to the engine, fuel system, or air intake, and recognizing these issues early on is key to effective repair and maintenance.

Engine Troubles

One of the most common problems with outdoor equipment is engine malfunction. The engine may struggle to start, run inefficiently, or even stall during use. These issues are often linked to:

- Clogged spark plugs

- Dirty air filters

- Fuel system blockages

- Worn-out ignition systems

To resolve engine-related problems, begin by inspecting the spark plug and cleaning or replacing it if necessary. Regularly changing the air filter and cleaning the fuel system can prevent clogs and improve engine performance. Additionally, checking the ignition system for wear can prevent unexpected failures during use.

Fuel and Airflow Problems

Fuel and airflow issues can drastically reduce the efficiency of your equipment. A lack of power or inconsistent operation is often due to problems in these systems. Some common causes include:

- Old or contaminated fuel

- Clogged fuel lines

- Blocked air intake

- Malfunctioning carburetors

For fuel issues, drain old fuel and replace it with fresh, clean fuel. Clean or replace the fuel lines if needed. Regularly inspect and clean the air intake to ensure proper airflow, and adjust or clean the carburetor to maintain optimal performance. Regular maintenance of these systems can prevent a range of performance issues.