Maintaining and repairing power tools requires a clear understanding of their internal structure. Having a visual representation of a tool’s components can make assembly, disassembly, and replacement processes significantly easier. This guide will help you navigate through the various sections of a chainsaw, making it simpler to identify parts and understand their functions.

Whether you’re replacing a worn-out piece or performing regular maintenance, knowing the layout of the tool is crucial for efficient repairs. Each part plays a specific role in ensuring smooth operation and safety. In this article, we will explore how to interpret these visual references and offer tips for making maintenance tasks more straightforward.

Familiarity with the internal parts can greatly reduce repair time and improve your chainsaw’s performance. By following this breakdown, you’ll have the knowledge needed to keep your tool in top shape for years to come.

Understanding the Chainsaw Component Breakdown

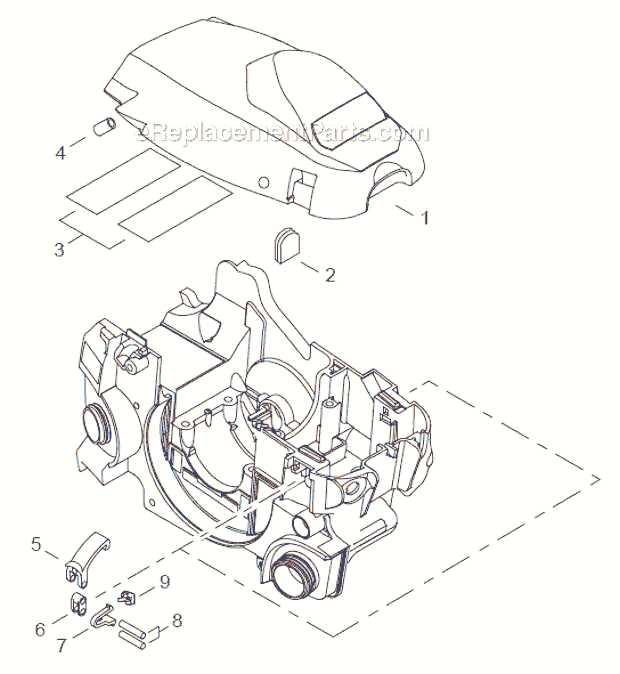

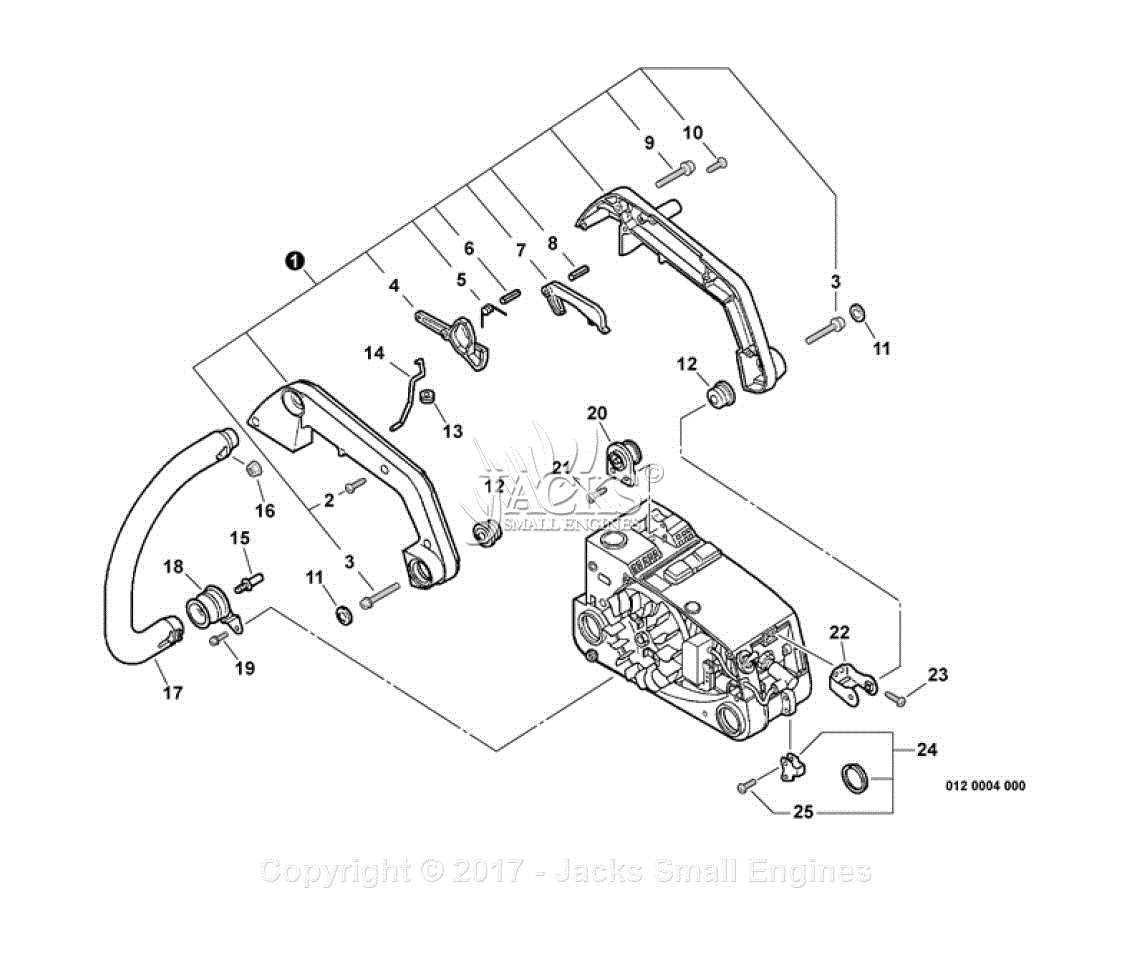

Having a visual reference of your chainsaw’s internal structure is essential for proper maintenance and repair. This tool layout shows how each individual part fits into the larger assembly, offering a clear map for anyone who needs to replace components or understand how the tool works. By understanding this schematic, you can confidently navigate through any issues that may arise during operation or service.

How the Diagram Helps with Repairs

With a detailed breakdown of each element, it becomes much easier to identify the parts that need attention. Whether it’s a malfunctioning piece or a worn-out component, the layout enables quick identification and helps guide you in acquiring the right replacement. The diagram often includes labels, helping you correlate the physical components with the listed items, streamlining the repair process.

Benefits for Regular Maintenance

Besides aiding in repairs, the breakdown also serves as a valuable tool for routine upkeep. Understanding how the parts interact and what their specific functions are can help you prevent wear and tear, ensuring the longevity of your equipment. Regular maintenance based on this visual guide allows you to spot potential issues before they become costly problems.

Key Components of the Chainsaw

Every chainsaw consists of several important elements that work together to ensure optimal performance. Each component has a specific role, from power generation to cutting action. Understanding these key parts allows users to make informed decisions when servicing or maintaining their equipment, as well as ensuring its efficiency during use.

Power Unit and Engine

The engine is the heart of any chainsaw, providing the necessary power to drive the cutting mechanism. It consists of several subcomponents, including the fuel system and spark plug, which ensure that the engine runs smoothly. A well-maintained engine allows for consistent power delivery, making tasks more efficient.

Cutting Mechanism

The cutting assembly includes the bar, chain, and sprocket, which are responsible for cutting through materials. The chain moves along the bar, and the sprocket drives the chain forward, ensuring that the saw performs at its best. Regular inspection and maintenance of this mechanism are crucial for maintaining sharpness and preventing breakdowns.

How to Use the Schematic Effectively

Understanding the visual layout of your tool is crucial for successful repairs and maintenance. A detailed schematic can guide you through the various components, helping you identify, replace, and repair specific sections without confusion. By learning how to read and interpret this visual reference, you can tackle maintenance tasks with confidence and accuracy.

Identifying Key Components

The first step in using the schematic effectively is to familiarize yourself with the labeled sections. Each part of the tool is represented in a way that makes it easy to match the physical components with their corresponding numbers or names. Understanding this system allows you to quickly locate the area needing attention and pinpoint the correct replacement if necessary.

Following the Assembly Order

When disassembling or reassembling the tool, following the sequence outlined in the schematic is essential. It shows how parts are interconnected and the correct order in which they should be assembled. This ensures that nothing is missed, preventing potential issues during reassembly and reducing the risk of errors.