When maintaining or repairing outdoor machinery, understanding the individual elements that make up your tool is crucial. Properly identifying each component and its function can save time and effort during repairs. Knowing how to assemble and disassemble the equipment with the right guidance helps prevent unnecessary damage and ensures smooth operation.

Having a clear overview of the system’s structure provides you with the knowledge to troubleshoot and replace faulty components effectively. Whether you are fixing a minor issue or performing regular maintenance, understanding the layout of all interconnected parts is essential. The proper approach can extend the lifespan of your machine and improve its overall performance.

Accessing detailed illustrations and clear references simplifies the process of understanding how everything fits together. With the right resources at hand, you can approach any repair task with confidence and precision, ensuring your equipment runs optimally throughout its use.

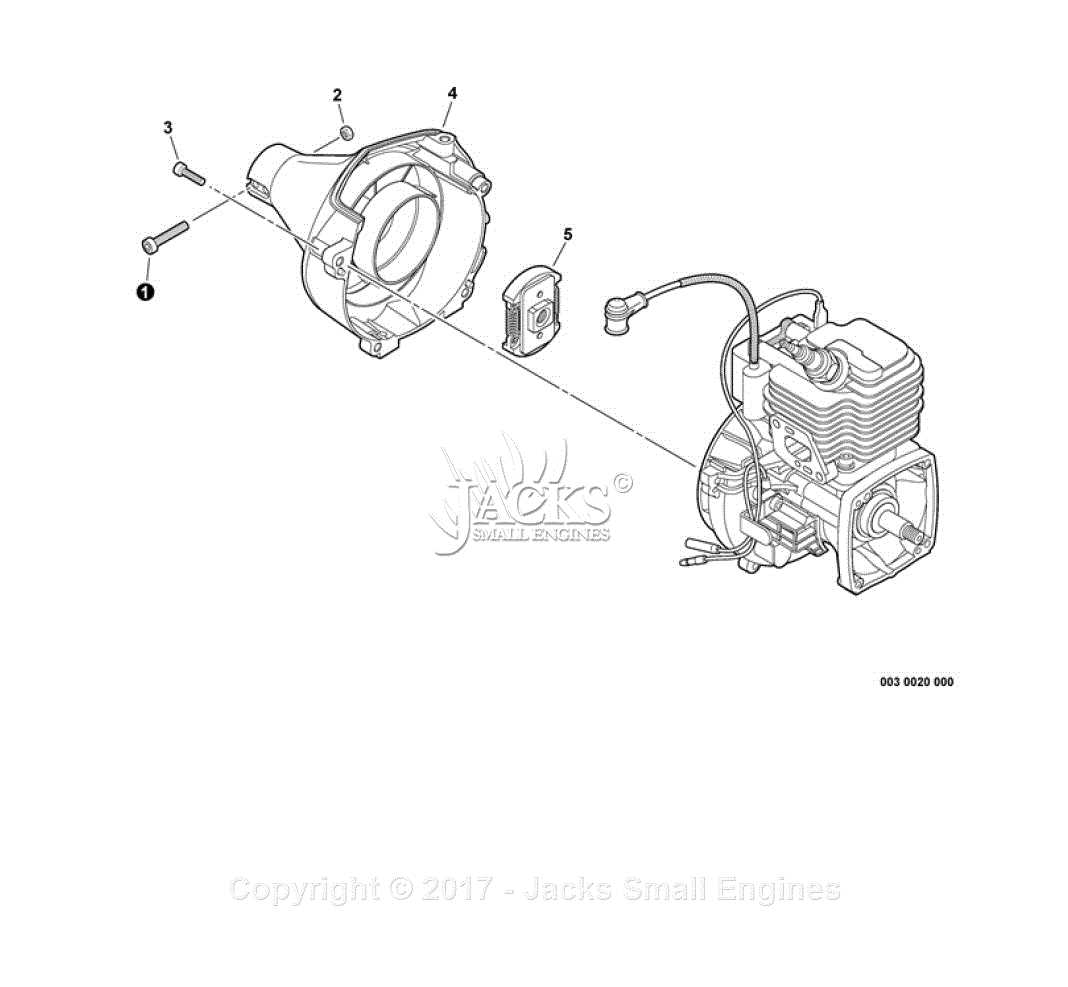

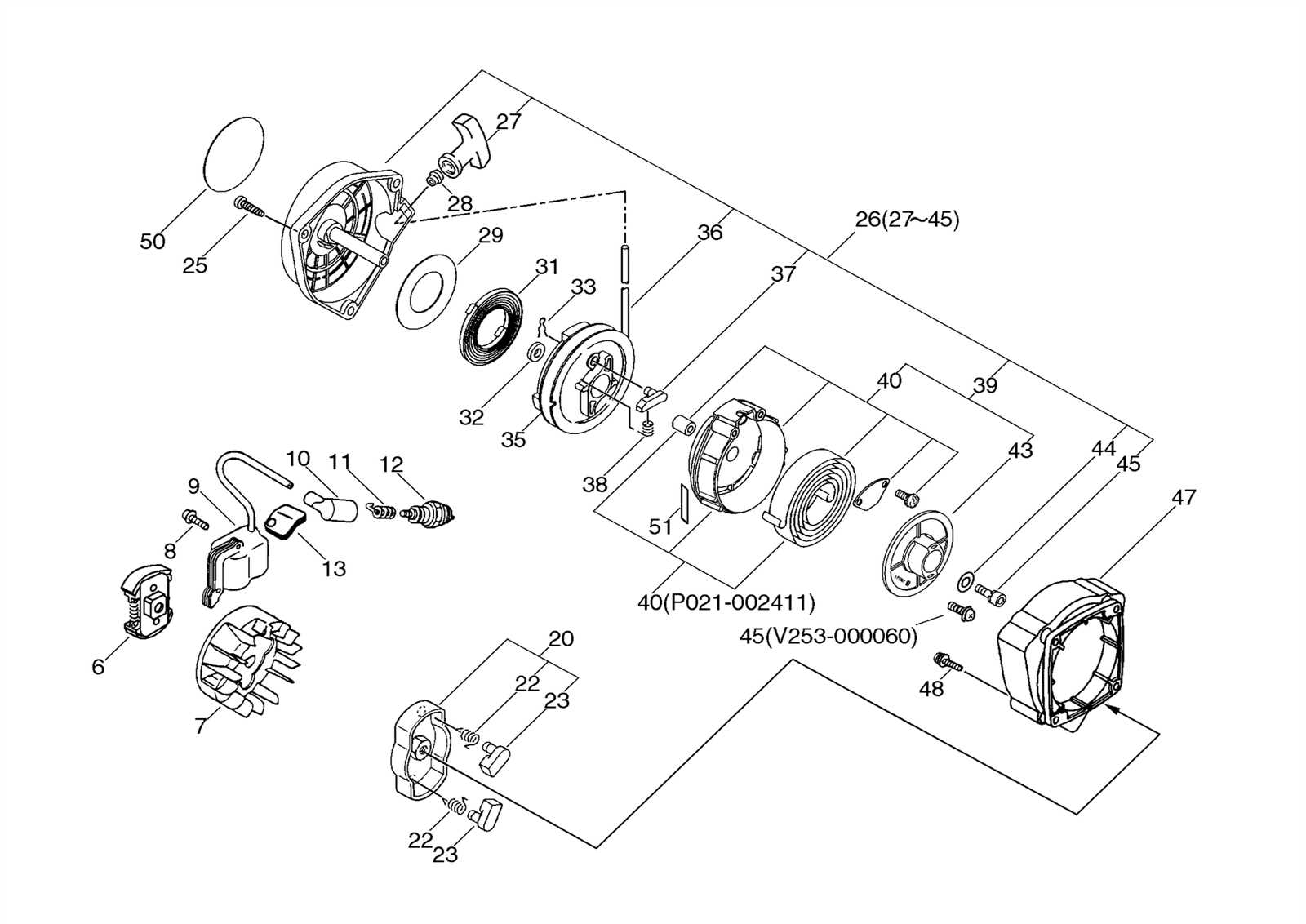

Understanding the Echo GT225 Parts Diagram

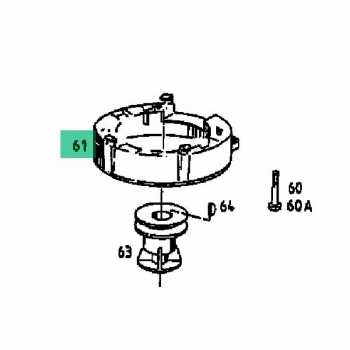

Having a comprehensive visual reference for your machine’s components can be incredibly helpful during repairs and maintenance. It allows you to identify each part’s role and how it interacts with other elements within the system. A clear representation of the various components is essential for anyone who needs to troubleshoot issues or replace damaged parts accurately.

By studying the detailed illustrations, you can gain a better understanding of where specific parts are located and how to disassemble or reassemble the unit properly. This knowledge can help prevent mistakes and save time when performing routine maintenance tasks or addressing mechanical failures.

With an organized guide to your equipment’s structure, you can approach repairs with more confidence. Whether you are replacing a broken piece or performing regular upkeep, having a visual reference to work from ensures that each task is carried out with precision and ease.

Common Issues and Parts Replacement Tips

Every piece of equipment experiences wear and tear over time, which can lead to various malfunctions. Understanding common issues and knowing how to replace worn or broken components can prevent costly repairs and improve performance. It’s important to identify the source of the problem quickly and determine the best course of action for replacement.

Identifying Common Failures

One of the most frequent issues is the deterioration of the fuel system, which can cause starting problems or reduced power. Often, clogged fuel lines or a malfunctioning fuel filter are the culprits. Regular inspection and cleaning of these components can avoid significant breakdowns. Additionally, issues with the ignition system, such as worn-out spark plugs, are another common cause of poor engine performance.

Replacement Tips for Longevity

Replacing components correctly is essential to maintaining optimal functioning. Always use high-quality replacements that match your equipment’s specifications to ensure compatibility and durability. Proper maintenance, including regular checks and timely replacements, will extend the lifespan of your equipment and prevent the need for frequent repairs.

How to Use the Echo GT225 Diagram Effectively

Utilizing a detailed visual guide is crucial for successful maintenance and repair. By referring to an organized layout of your equipment’s components, you can easily identify the necessary parts and their specific functions. This guide helps streamline the process of disassembling, replacing, or fixing any issues you encounter.

To make the most of the visual reference, begin by familiarizing yourself with the entire structure. Understand how each part connects and interacts with the others. When troubleshooting, use the diagram to pinpoint the location of the malfunctioning component, ensuring a targeted and efficient repair.

Additionally, always cross-check the part numbers or specifications shown in the visual guide with the parts you’re using for replacements. This will ensure compatibility and avoid unnecessary errors during the repair process. With these practices, you’ll be able to manage your equipment’s upkeep more confidently and effectively.