For effective maintenance and repairs, it’s essential to have a clear understanding of the different elements that make up garden machinery. Recognizing the individual components allows users to identify issues, locate replacement parts, and keep their tools functioning smoothly. Whether you’re a DIY enthusiast or a professional landscaper, having knowledge of how your equipment is assembled can save time and effort during troubleshooting.

Once you familiarize yourself with the various components of these machines, you can easily spot signs of wear and determine which parts need attention. This understanding can also help in improving the longevity and efficiency of your tools, ensuring they perform well for years. The process of identifying and replacing faulty parts becomes straightforward when you have a clear view of the inner workings of your equipment.

Understanding Garden Tool Components

Maintaining and repairing garden machinery begins with an understanding of its key components. Each tool is made up of a variety of interconnected parts that work together to perform specific tasks. Recognizing the function and location of each part ensures you can effectively troubleshoot, replace damaged elements, and maintain optimal performance. This knowledge is invaluable for both routine care and major repairs, allowing you to extend the life of your equipment.

Key Elements of Garden Machinery

At the heart of most garden tools is a powerful motor that drives the mechanical parts. This motor is usually connected to a set of moving blades or cutting elements, which require proper alignment and tension. A range of smaller components, such as switches, bearings, and springs, support the tool’s functionality and contribute to its overall durability. Understanding the role of each part helps in identifying where issues might arise and how to address them effectively.

How to Identify Faulty Components

When issues arise, knowing which component is causing the problem can save both time and effort. For example, worn-out cutting blades or a malfunctioning motor can hinder the tool’s performance. By regularly checking the main components and looking for signs of wear, such as cracks, rust, or reduced efficiency, you can pinpoint the parts in need of repair or replacement. Familiarity with the inner workings allows you to perform preventive maintenance and avoid costly repairs in the future.

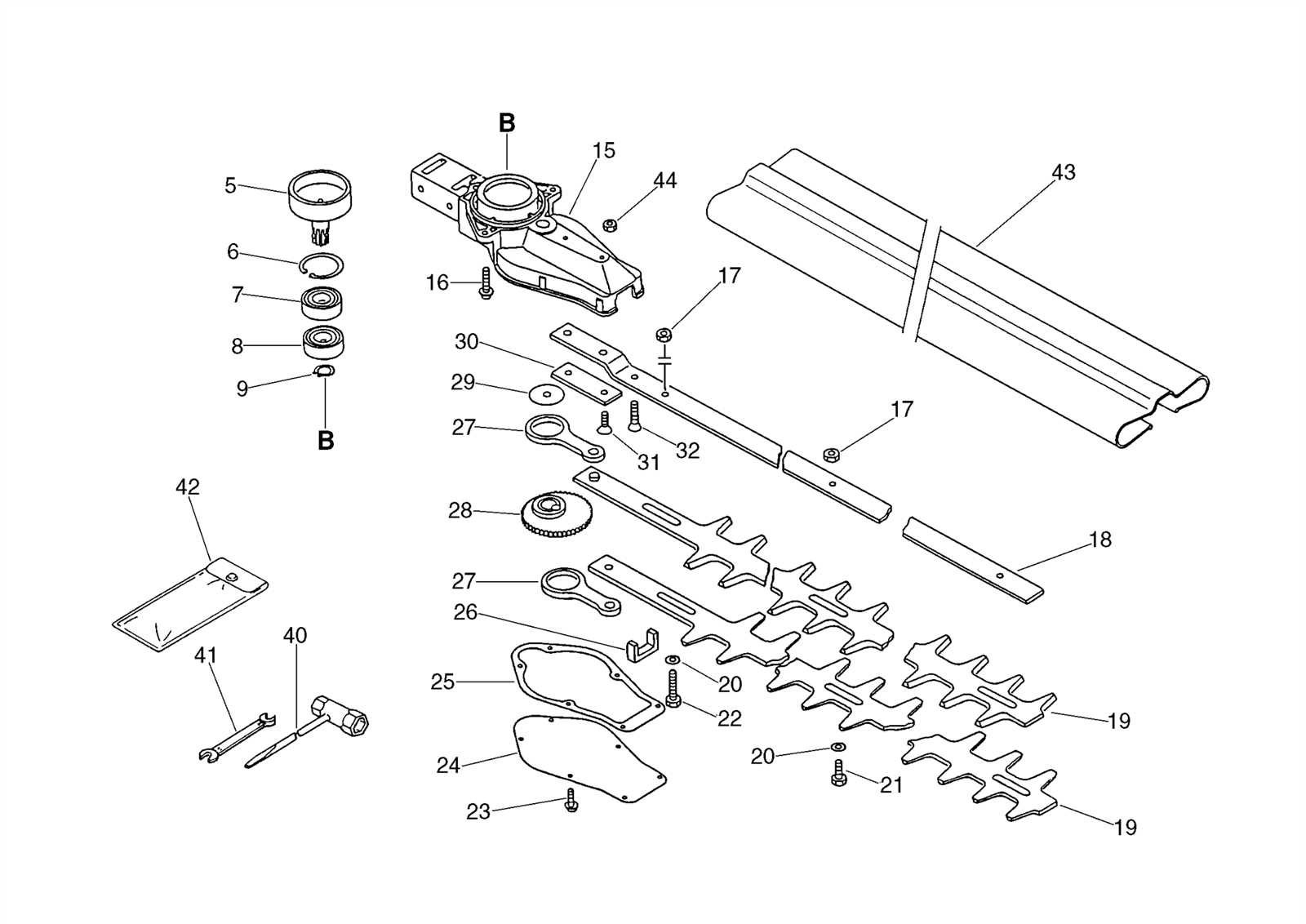

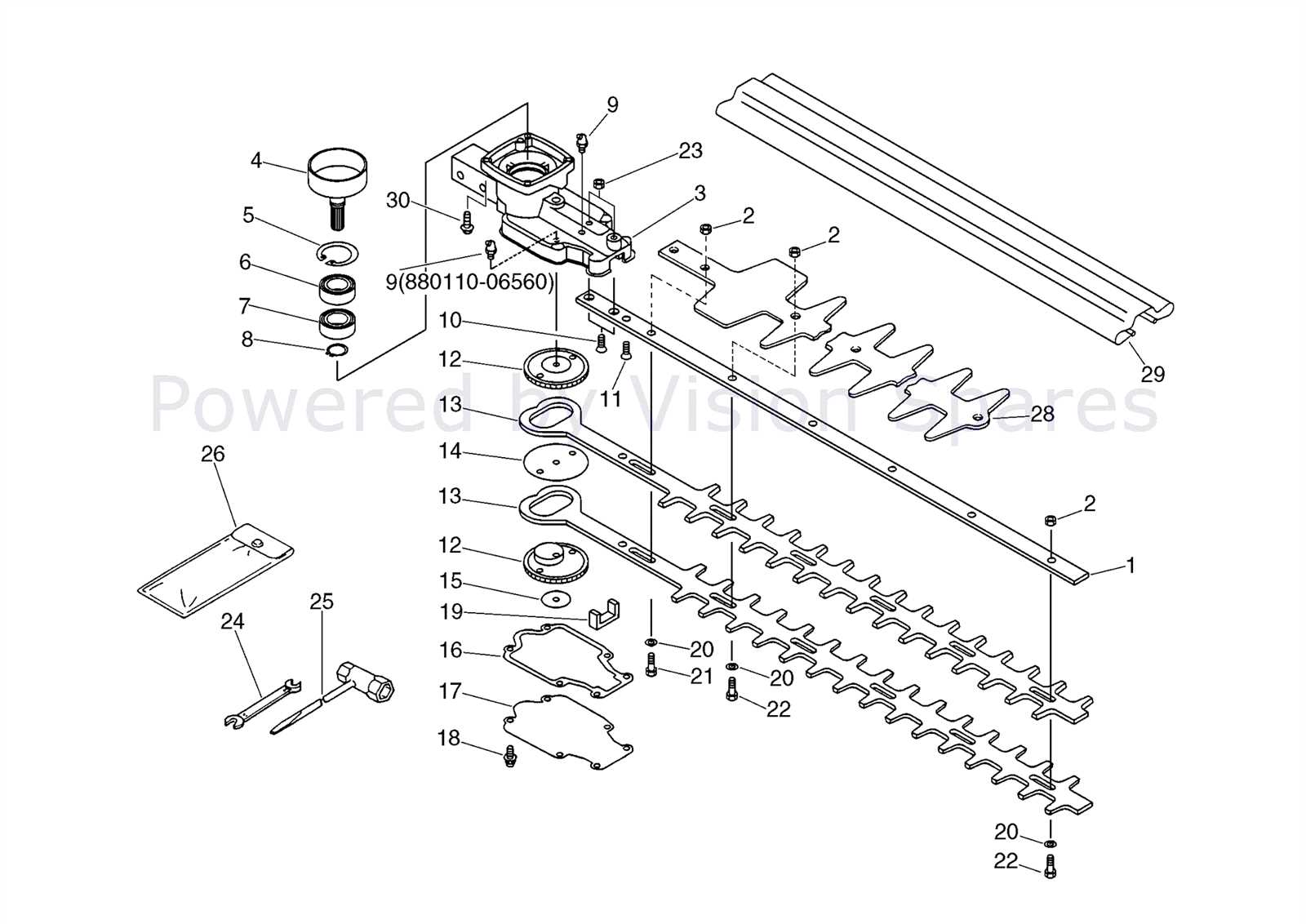

How to Read Garden Tool Assembly Charts

Understanding the layout and structure of assembly charts is crucial for effective tool maintenance. These charts provide a visual representation of all the individual components and how they fit together. By reviewing this detailed guide, users can learn to identify each part, recognize their function, and understand how to assemble or disassemble the equipment for repair or cleaning. The key is to familiarize yourself with the markings, labels, and symbols commonly used to illustrate each part’s placement and relationship with others.

Interpreting Symbols and Labels

Assembly charts often use symbols, numbers, and letters to indicate specific components. These symbols are typically standardized and easy to identify once you become familiar with them. Numbers or part codes are linked to each item, allowing you to cross-reference the diagram with part catalogs or manuals. It’s important to know where these identifiers are located on the chart to quickly find the part you need and ensure accurate replacements.

Understanding Part Relationships

Charts not only show individual components but also their relationships within the tool’s structure. For example, you might see how a particular gear interacts with the motor or how the blade assembly connects to other moving parts. This understanding is vital when troubleshooting problems or conducting repairs, as it reveals how each component’s performance impacts the overall functionality of the machine.

Common Garden Tool Repair Components

When it comes to maintaining and repairing garden equipment, certain components tend to require attention more frequently. These parts often undergo wear and tear due to constant use, exposure to the elements, or mechanical stress. By recognizing the most common components that need replacement, users can ensure their tools are always ready for use and perform optimally.

Among the most common repair items are the cutting blades, which can become dull or damaged after extended use. These blades are essential for precise cutting and should be checked regularly for any signs of wear. Another frequent issue involves the motor components, such as the brushes or bearings, which may wear down over time and reduce efficiency. Additionally, the housing or casing might crack, affecting the tool’s durability and safety. Replacing these components is crucial to maintain the tool’s performance and prolong its lifespan.