When it comes to maintaining outdoor power tools, understanding the internal components and how they fit together is crucial for effective repairs. Having a detailed reference for each part can help diagnose issues and ensure the equipment runs smoothly for years to come.

Knowing your tool’s structure is key to identifying faulty components quickly. Whether you’re dealing with a malfunction or simply performing routine maintenance, familiarity with how the pieces interact can save both time and money.

With a clear breakdown of the various components, you can gain confidence in handling repairs yourself. This guide will walk you through the essential parts, offering helpful insights for troubleshooting and upkeep. By the end, you’ll have a deeper understanding of your equipment’s design and be ready to tackle maintenance tasks efficiently.

Understanding the Equipment Breakdown

To effectively maintain and repair your outdoor tool, it’s essential to have a clear understanding of its individual components. Knowing how each part functions and interacts with others allows for easier troubleshooting and ensures the longevity of the machine. This section will help you grasp the key elements of the tool’s design and how they contribute to its overall performance.

Identifying Core Components

The central parts of the machine are the foundation for its operation. They work in tandem to provide optimal performance. By recognizing the function of each core component, you can pinpoint issues more efficiently and avoid unnecessary replacements. Whether it’s the power source or mechanical elements, understanding their role is crucial for successful maintenance.

How Parts Work Together

It’s not just about knowing what each part does; it’s about understanding how they all work together to power the tool. From the ignition system to the exhaust, the entire system is designed to work in harmony. A well-rounded understanding of the interconnections between these parts ensures that repairs or replacements are done correctly and without causing further damage.

Key Components of Outdoor Power Equipment

Every piece of outdoor power equipment relies on a set of essential components that allow it to function efficiently. Understanding these key elements is vital for troubleshooting, performing repairs, and ensuring the tool operates at peak performance. Each part plays a specific role, contributing to the overall efficiency and durability of the machine.

The engine, fuel system, and ignition components are among the most important. These parts work together to provide the power needed for the equipment to run. Additionally, mechanical elements such as the drive system and exhaust are integral to smooth operation and the removal of waste gases.

Other critical elements include the air filter and carburetor, which ensure that the engine receives a steady supply of clean air and fuel. The starter system, along with the throttle control, allows for easy operation and fine-tuning of the machine’s performance. Understanding how these components interact helps maintain the tool and avoid potential breakdowns during use.

How to Use the Equipment Breakdown for Repairs

Having a detailed breakdown of your equipment is an invaluable tool when it comes to repairs. It provides a clear overview of all the essential components and their placement within the machine. By referencing this guide, you can identify specific parts that need attention and efficiently plan the repair process.

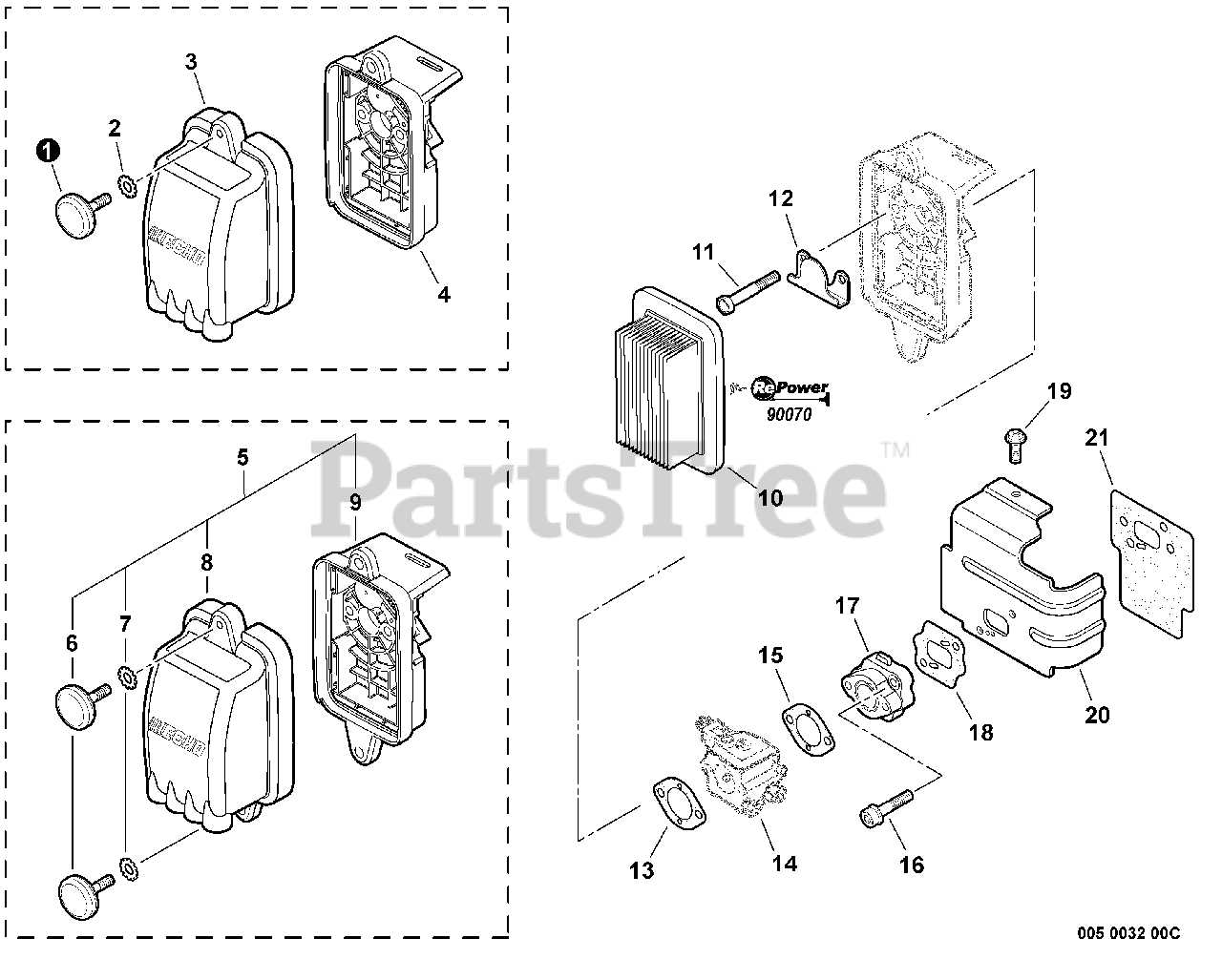

To begin, locate the component that is malfunctioning or showing signs of wear. With the detailed map in hand, you can easily match the faulty part with its corresponding location. This visual guide eliminates the guesswork, allowing for more precise and faster repairs. It also helps you understand the relationship between different components, ensuring no part is overlooked.

Once you’ve identified the damaged or worn-out part, check the recommended replacement procedures. The breakdown will often highlight the necessary steps, including which parts need to be removed before accessing the damaged component. Following this structured approach ensures that you avoid unnecessary disassembly and minimizes the risk of damaging other parts during the repair process.