When maintaining or repairing outdoor equipment, having a clear understanding of its individual components is essential. This knowledge helps identify parts that need attention and ensures smooth operation. Knowing the structure and assembly of each section can prevent unnecessary mistakes and save time during repairs.

Accurate identification of each element is the first step in any maintenance task. With the correct information, replacing worn-out or damaged parts becomes more straightforward. A comprehensive guide makes it easier to navigate through this process and ensures that the equipment functions properly after each repair.

Whether you’re replacing a damaged component or simply performing routine checks, understanding how all the pieces fit together is crucial for optimal performance. This guide will help you recognize the various parts involved and assist in making informed decisions when it’s time for maintenance or upgrades.

Understanding the Trimmer Components

Maintaining outdoor power tools requires a clear grasp of the various elements that make up the machinery. Knowing how each part functions and contributes to the overall operation ensures that your equipment runs efficiently. Familiarizing yourself with these components allows for better decision-making when it comes to repairs or upgrades.

Key Sections of the Tool

Every piece of equipment has specific areas that are crucial for its functionality. The motor and drive system are often the heart of the machine, powering the cutting mechanism. Other sections, such as the fuel system, control switches, and protective covers, also play vital roles in ensuring safety and performance. Understanding each of these sections helps pinpoint where issues may arise.

Assembly and Maintenance Considerations

Knowing how all the elements are assembled and interact with each other is fundamental. Routine maintenance becomes much easier when you have an understanding of where to focus your efforts. For example, inspecting and cleaning the air filter, checking the fuel lines, and ensuring proper lubrication of moving parts will prolong the lifespan of the equipment and improve its efficiency.

How to Identify Essential Components in the Blueprint

Understanding the layout and structure of your equipment is key when identifying crucial elements. Each tool consists of various sections that work together to ensure smooth operation. By recognizing these essential components, you can easily spot areas that need attention or replacement. This knowledge simplifies maintenance tasks and enhances overall tool performance.

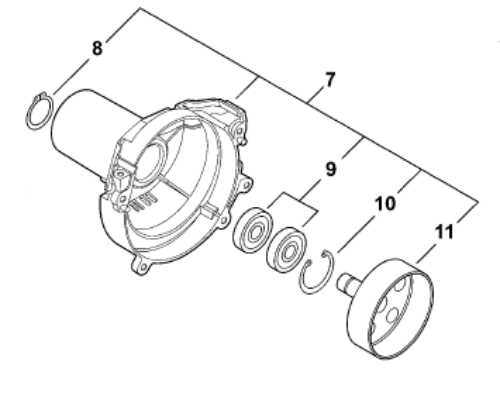

Start by focusing on the most critical sections, such as the motor, fuel system, and drive components. These elements are usually central to the tool’s functionality and often require the most care. Once familiar with the primary components, it becomes easier to identify supporting parts that contribute to efficiency and safety.

Pay attention to labels and markings in the schematic. These details can guide you in distinguishing between different types of elements. A clear understanding of each part’s role in the tool helps you make informed decisions during repairs or replacements, ensuring that everything functions as intended.

Step-by-Step Guide to Replacing Damaged Components

Replacing damaged elements in your outdoor equipment is a straightforward process when approached systematically. By following a clear, methodical guide, you can efficiently swap out malfunctioning sections and restore the tool’s performance. Knowing what to do at each step helps prevent mistakes and ensures the job is completed correctly.

Preparing for the Replacement

Before starting the replacement, make sure you have the necessary tools and a replacement part that matches the specifications. Turn off the machine and disconnect it from any power or fuel sources to ensure safety during the process. It’s also important to wear protective gloves and eyewear to avoid any injuries.

Step-by-Step Procedure

Once you’ve prepared your workspace, begin by carefully removing any covers or panels that obstruct access to the damaged component. Follow the assembly instructions in reverse to carefully detach the old part. After removing the faulty section, replace it with the new one, ensuring that it is securely connected and aligned properly. Once the replacement is complete, reassemble the tool and perform a test to confirm that everything is functioning as expected.