Maintaining a garden tool requires a clear understanding of its individual elements. Each component plays a crucial role in ensuring the device operates effectively and reliably. Recognizing how these parts fit together is key to troubleshooting and repair.

Proper identification of each element allows users to confidently make necessary repairs and replacements. This guide provides a detailed breakdown of how these components interact, helping users to maximize performance.

By familiarizing yourself with the structure of your equipment, you can easily perform maintenance tasks and ensure its longevity. Whether it’s for routine cleaning or fixing a malfunction, knowing the parts inside and their function is essential.

Understanding the Lawn Tool Components

Every garden tool consists of various elements that work together to perform its intended function. Each component serves a specific purpose, and understanding these roles can help you troubleshoot issues and improve the tool’s performance. Familiarizing yourself with the different sections is essential for efficient maintenance and proper use.

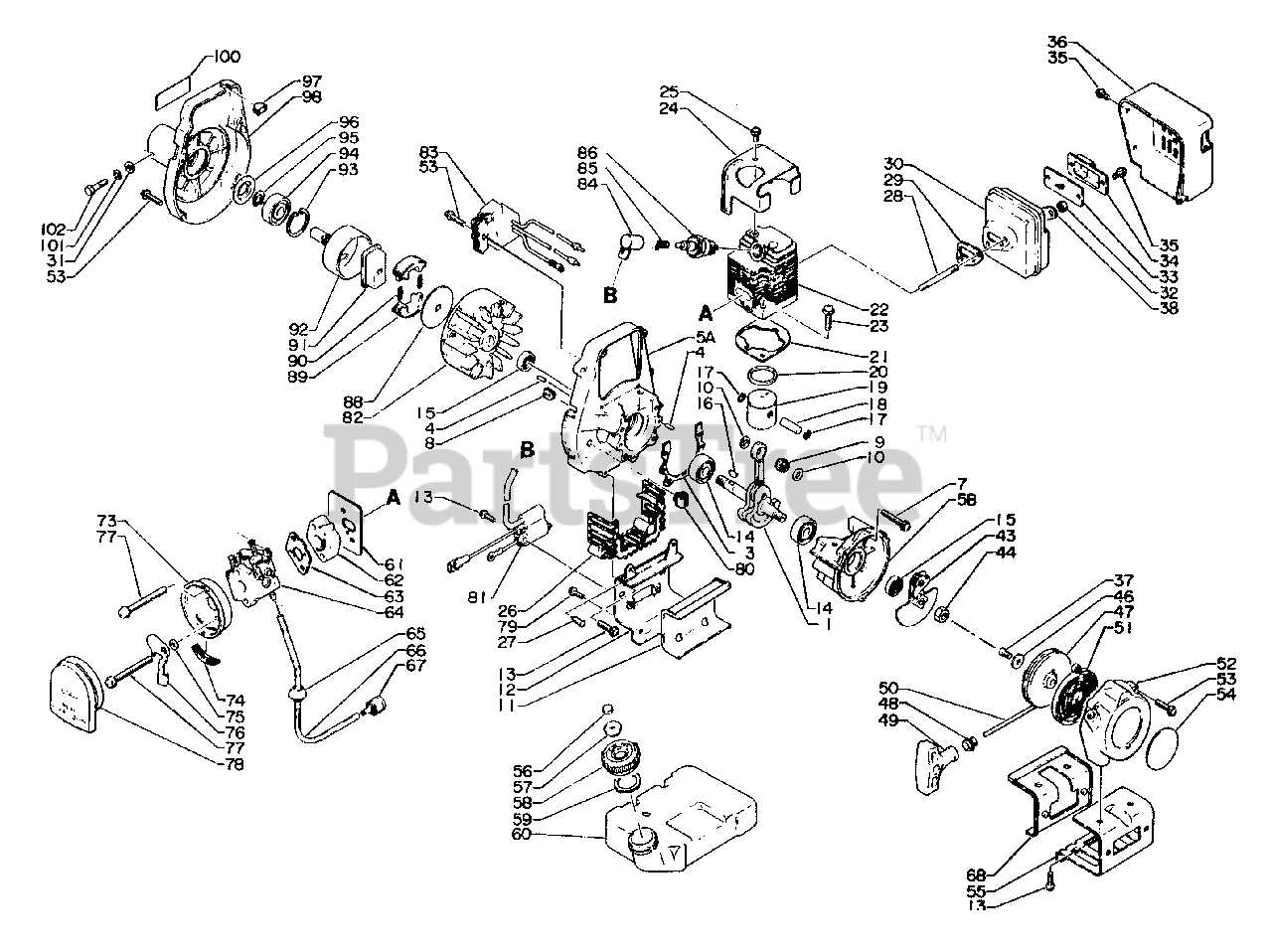

Main Body and Motor Assembly

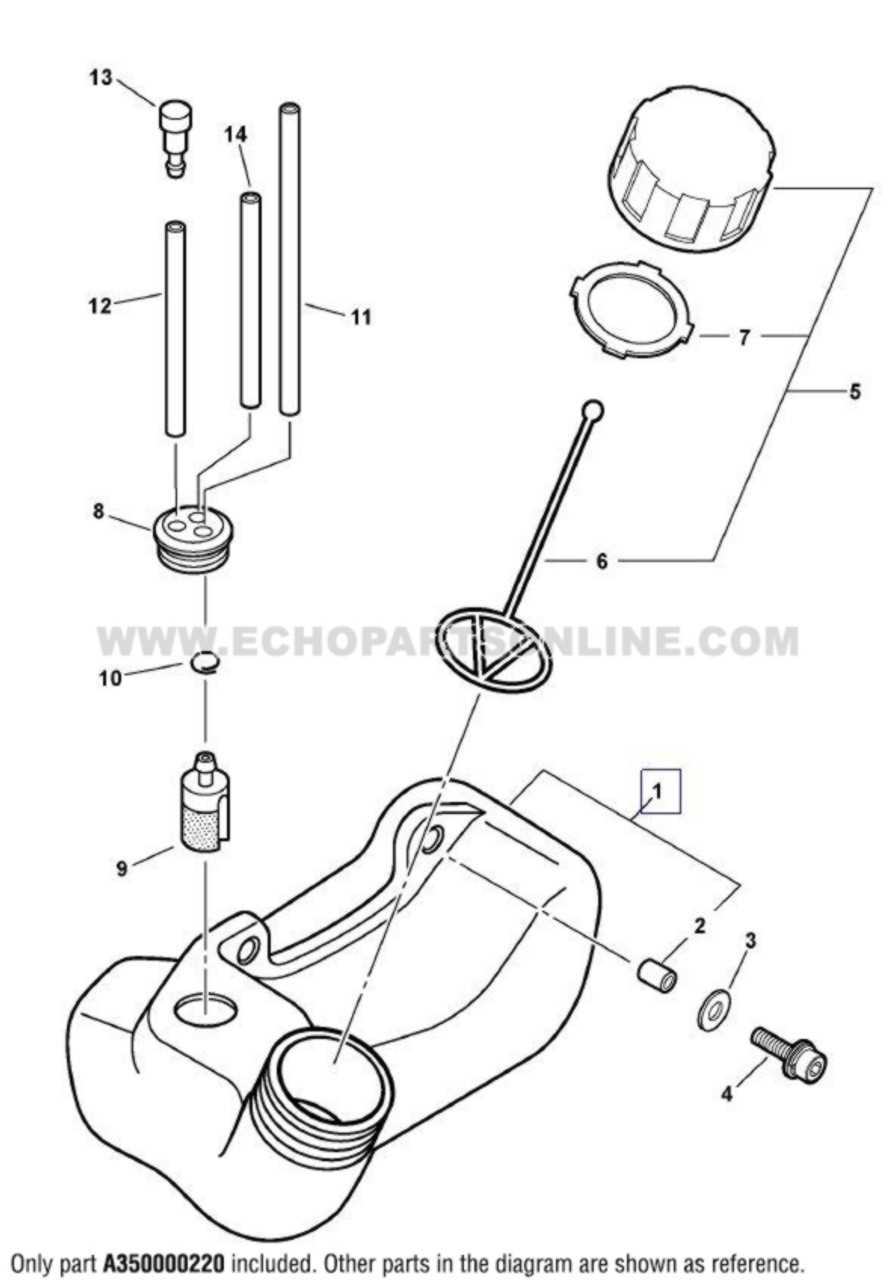

The central unit houses the engine or motor, which is the driving force behind the tool. It converts energy into mechanical motion, allowing the device to function. This section is typically the heaviest and most critical, as any failure here can result in the entire tool not working as intended. Proper care of this component involves regular checks for wear and ensuring it remains securely mounted.

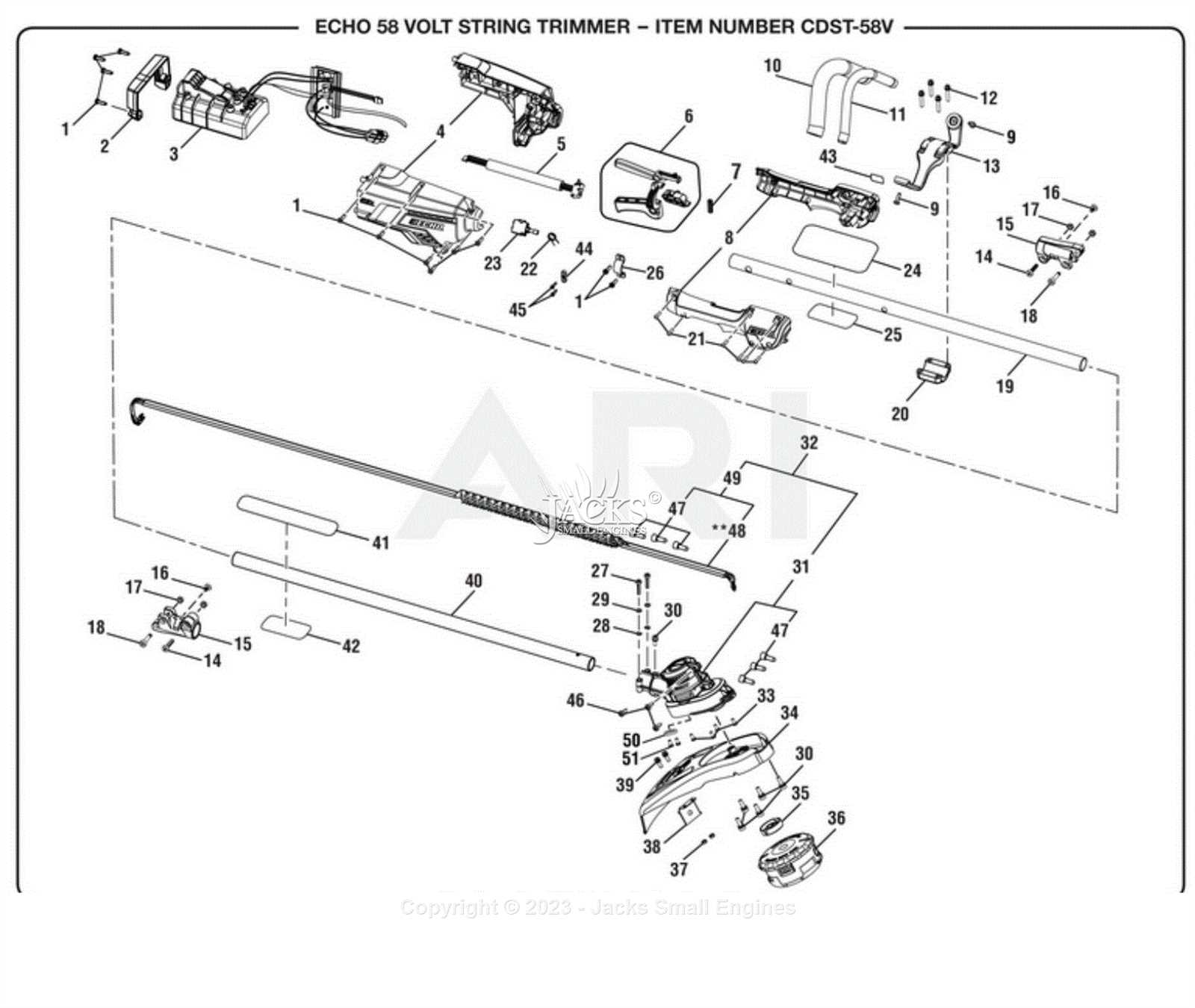

Cutting Mechanism and Housing

Located at the operational end, the cutting mechanism is responsible for executing the actual task. It often includes blades, spools, or other cutting tools, depending on the device’s design. The housing around this area protects the mechanism from external damage while also containing debris. Regular cleaning and checking for damage in this part are crucial for maintaining sharpness and overall efficiency.

How to Identify Lawn Tool Components

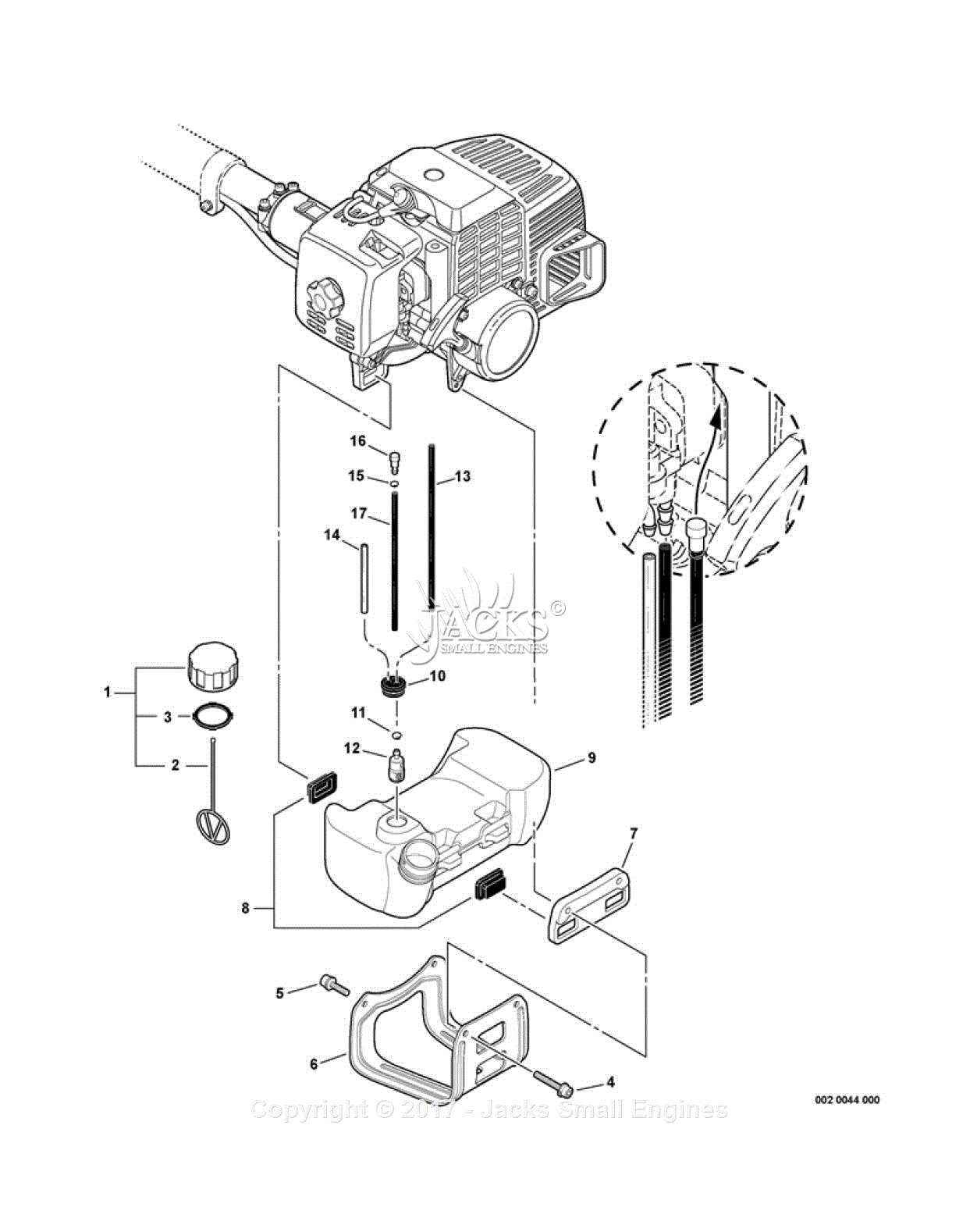

Recognizing the different elements of a garden tool is essential for effective maintenance and repairs. Each component has a specific function, and understanding how to identify them ensures that you can handle issues promptly and with confidence. Proper identification helps avoid mistakes during assembly or when ordering replacement pieces.

Start with the core structure. The motor or engine is typically the most prominent feature, often located at the central unit. From there, follow the connections leading to other elements like the cutting assembly, handles, and support frames. It’s important to recognize these key components and how they interact with one another.

Consulting the manufacturer’s manual can also aid in identifying these components. It provides a visual representation and descriptions of each element, making it easier to match parts with their respective functions. Knowing the correct names and functions allows you to troubleshoot effectively and maintain your tool for longer-lasting performance.

Step-by-Step Lawn Tool Assembly Guide

Assembling a garden tool correctly is crucial for optimal performance. Following a clear, step-by-step approach ensures that every component is securely connected and functioning as it should. This guide provides a simple process for putting together your equipment efficiently and safely.

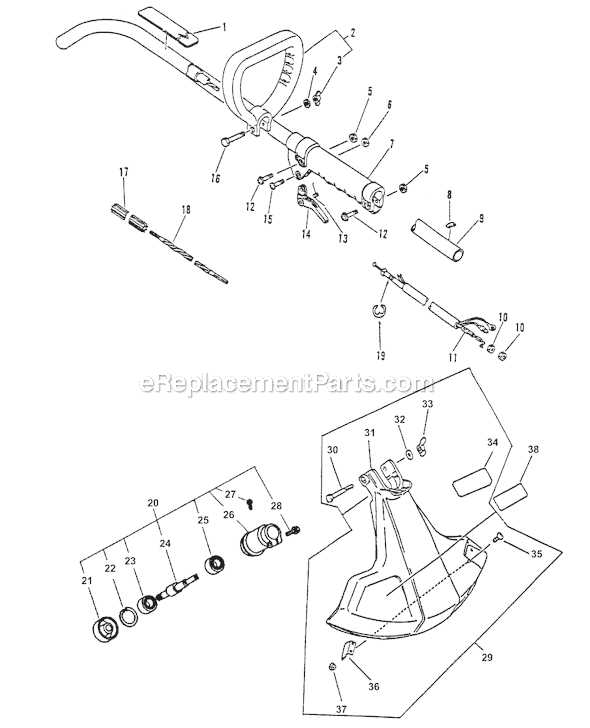

Preparing for Assembly

Before starting, gather all necessary components and tools. Make sure you have a clean, spacious area to work in. Check that all parts are present and undamaged to avoid any issues during assembly.

- Ensure the motor or engine is ready for attachment.

- Verify that the handle and support frame are in good condition.

- Check the cutting mechanism for any damage or wear.

Step-by-Step Assembly

Now, begin the assembly process by following these steps:

- Attach the motor to the main frame, ensuring it is securely fastened.

- Connect the handle to the frame, adjusting it for comfort and control.

- Install the cutting mechanism, making sure it is properly aligned.

- Double-check all connections to ensure everything is tight and stable.

Once all parts are securely in place, perform a test to verify that the tool operates as intended. If any parts feel loose or there are signs of malfunction, recheck your assembly steps.