When it comes to maintaining and repairing complex machinery, having a clear understanding of the individual elements that make up the system is crucial. Knowing how each part interacts with the others ensures smoother operations and more effective troubleshooting. This section will help you familiarize yourself with the essential components, providing valuable insights into their functions and interconnections.

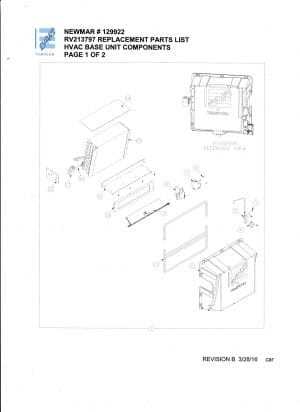

Accurately identifying parts and their placement is key to performing efficient maintenance and repairs. By using detailed reference materials, you can quickly locate the necessary elements and make informed decisions during repair or upgrade processes. This guide will serve as a reliable resource for anyone looking to improve their technical knowledge and enhance their troubleshooting capabilities.

Mastering this understanding will not only save time but also help avoid costly mistakes, ensuring that the system operates at its full potential. Whether you’re a technician or a DIY enthusiast, this resource will equip you with the tools needed to confidently navigate the system’s structure and enhance its longevity.

Understanding System Components

Every mechanical system consists of several interconnected elements, each serving a specific purpose. Recognizing the function of each component is essential for anyone involved in maintenance or repair. A deep understanding of how the individual pieces interact helps ensure the smooth operation of the entire system. In this section, we’ll explore the key components and their roles within the broader assembly, offering a clearer picture of their importance.

Components are typically grouped based on their function within the overall machinery. Some are responsible for power distribution, while others handle control or cooling functions. Understanding these groups and their relationships is vital when troubleshooting issues or replacing worn-out elements. This knowledge allows you to identify the root cause of any malfunction quickly, ensuring repairs are both efficient and accurate.

By learning how to recognize each component and its specific role, you can enhance your ability to perform effective repairs and maintenance. Familiarity with the system’s structure minimizes downtime and maximizes performance, leading to longer equipment lifespan and reduced repair costs. With the right knowledge, you’ll be able to maintain the system in peak condition for years to come.

How to Read the System Blueprint

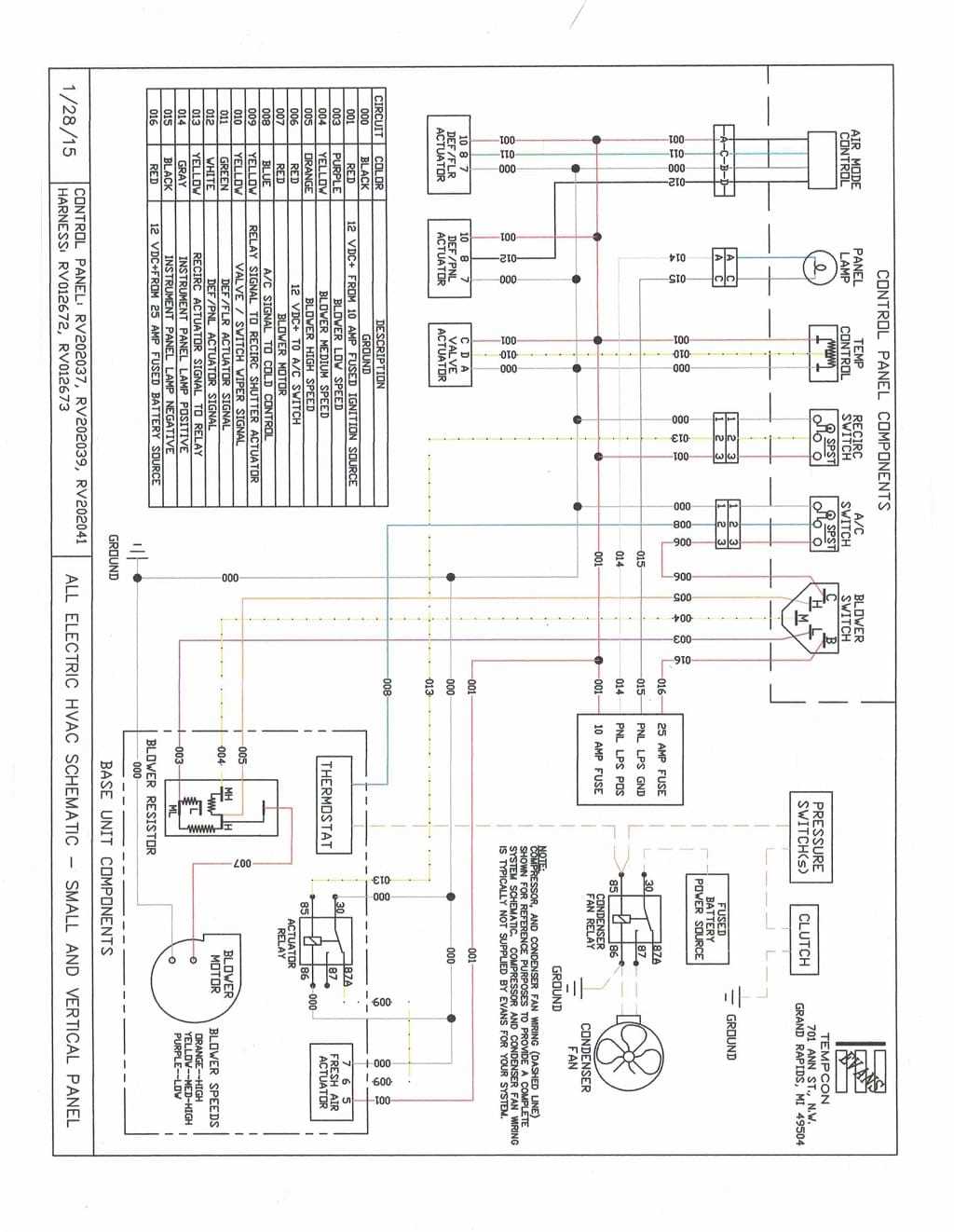

Interpreting a detailed schematic or blueprint is a crucial skill for anyone working with complex machinery. These visual representations provide an organized view of how individual components fit together and interact within the overall system. Understanding how to read such a guide helps you identify specific parts, understand their roles, and ensure proper placement during assembly or repair.

Identifying Components and Symbols

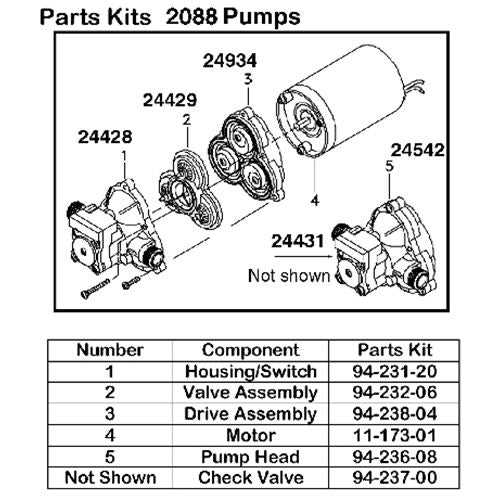

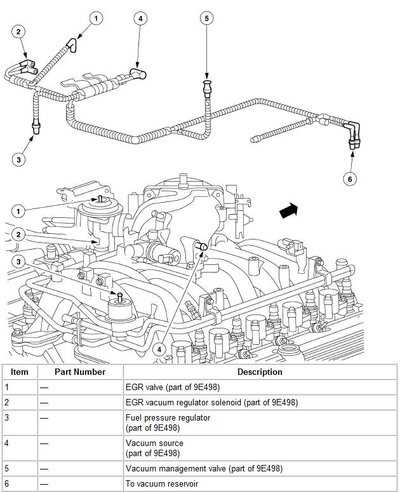

The first step in reading any technical schematic is learning to recognize the symbols and labels used for each element. These symbols are standardized to represent various parts of the system, from valves to control units. Each component is typically accompanied by a reference number or code, making it easier to locate the corresponding physical item or replacement part.

Following the Connections

Once the individual parts are identified, the next step is understanding how they connect with one another. The lines and arrows on the blueprint show the flow of energy, fluids, or signals between different components. By tracing these connections, you can understand the system’s operation and identify any potential weak points or areas prone to failure.

Mastering this process will make repairs faster and more accurate, as you’ll be able to pinpoint specific components quickly. With a solid grasp of reading schematics, you’ll gain confidence in working with complex systems, ensuring smoother maintenance and fewer errors during repairs.

Common Repairs Using the Blueprint

When dealing with a malfunctioning system, having a detailed reference guide is invaluable for identifying and resolving issues efficiently. By following the schematic, you can pinpoint problematic components and understand how they interact with other elements, allowing for precise and effective repairs. This section will highlight some of the most common repair tasks that can be tackled using such a reference.

One of the most frequent repairs involves replacing worn-out or damaged components. With the help of the schematic, you can easily locate the faulty part and identify the correct replacement. This eliminates unnecessary guesswork, ensuring that the new component is compatible with the rest of the system and that the repair is done properly.

Another common issue is addressing faulty connections or misalignments. By following the blueprint’s layout, you can trace the connections between parts and determine if any have come loose, are damaged, or require adjustment. This ensures that everything is connected properly and the system runs as intended.

In many cases, the reference guide also helps with diagnosing more complex issues, such as electrical malfunctions or fluid blockages. By understanding the flow and interaction of different system elements, you can pinpoint the source of the problem and take the necessary steps to fix it, reducing the risk of further damage.

Using a blueprint effectively not only saves time but also reduces the chance of errors, leading to more reliable and long-lasting repairs. Familiarity with this resource empowers technicians to tackle a wide range of maintenance tasks confidently and accurately.