When it comes to efficient temperature control, understanding how a system operates is essential for maintaining and troubleshooting it. Every device designed to regulate heat is composed of various components that work together to ensure proper function. By knowing the individual roles of these elements, users can easily identify issues and take the necessary steps for resolution.

In this section, we will break down the essential components that contribute to the effective functioning of a cooling mechanism. The goal is to provide a comprehensive overview that will help you grasp how each piece contributes to overall efficiency. Whether you are a DIY enthusiast or someone interested in learning more about these systems, understanding these key elements is the first step toward achieving better performance.

Understanding Key Components of Evaporative Coolers

Every cooling mechanism relies on various individual elements working together to achieve optimal efficiency. Each component plays a crucial role in maintaining airflow, regulating temperature, and ensuring the system operates smoothly. Understanding these components is essential for both users and technicians to diagnose issues, perform maintenance, and improve the overall performance of the unit.

Primary Elements and Their Functions

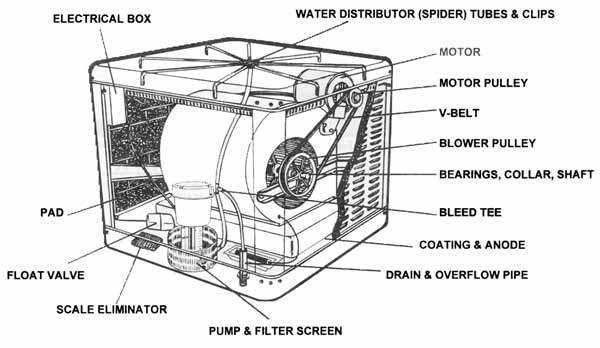

The foundation of any efficient system lies in its core components. These usually include elements designed to manage airflow, moisture distribution, and heat exchange. A fan is essential for circulating air, while filters are responsible for trapping dust and other particles. Additionally, the system uses water to absorb heat and cool the air, often through an integrated mesh or pad system that allows moisture to evaporate into the airstream.

Maintenance and Troubleshooting Considerations

Regular maintenance of the individual elements can significantly extend the lifespan and improve the performance of the system. Key parts such as filters, pumps, and air ducts require periodic cleaning and inspection. Neglecting these can lead to reduced efficiency or even system failure. Understanding how each element functions allows for better troubleshooting and ensures that the entire mechanism continues to perform effectively when needed most.

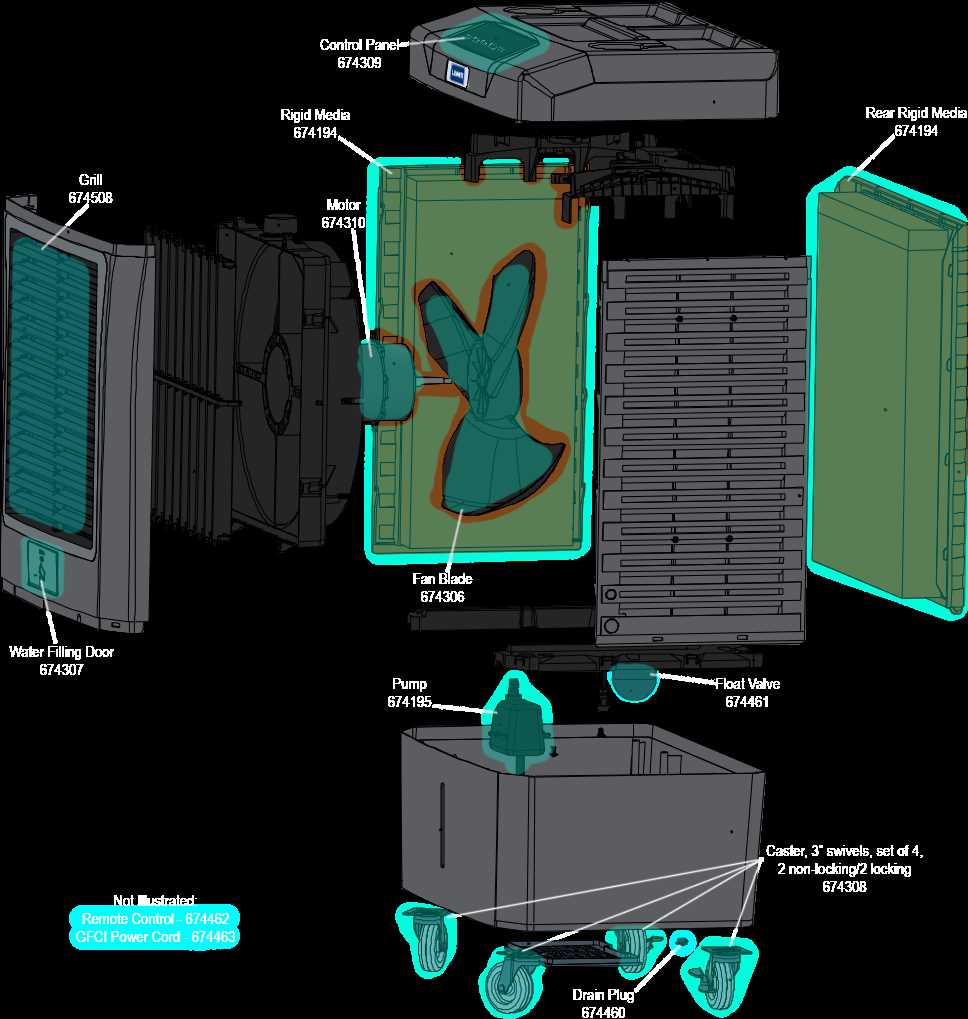

How to Read an Evaporative Cooler Parts Diagram

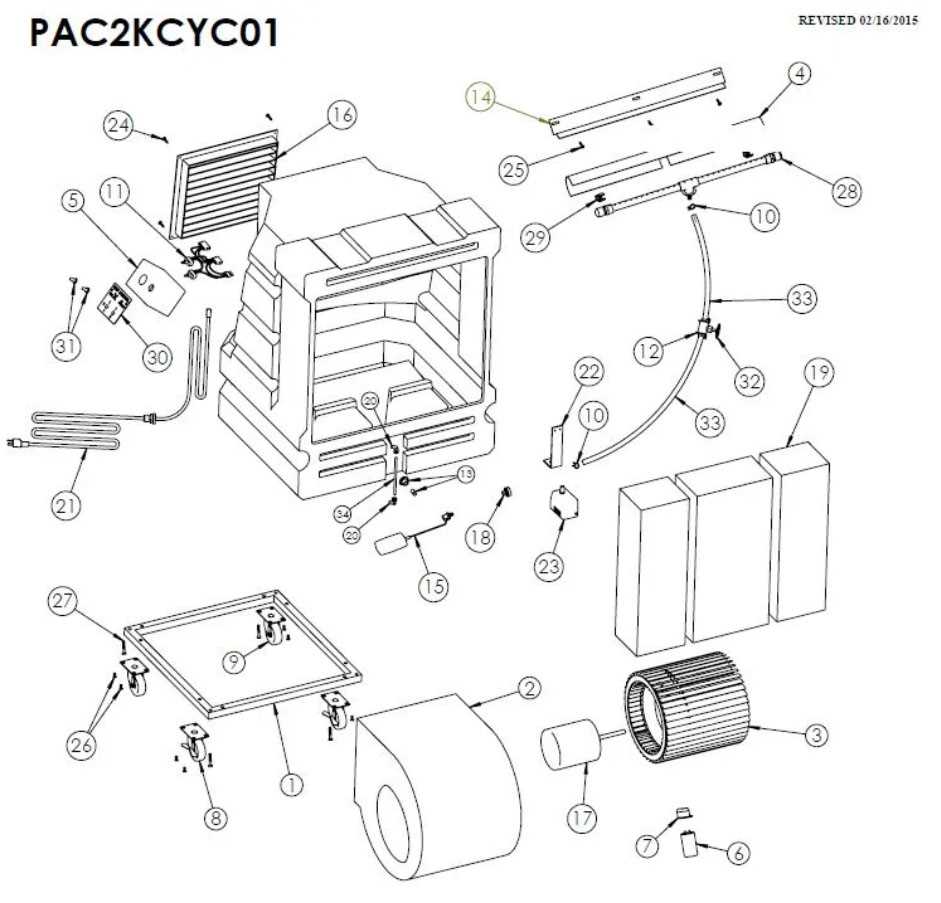

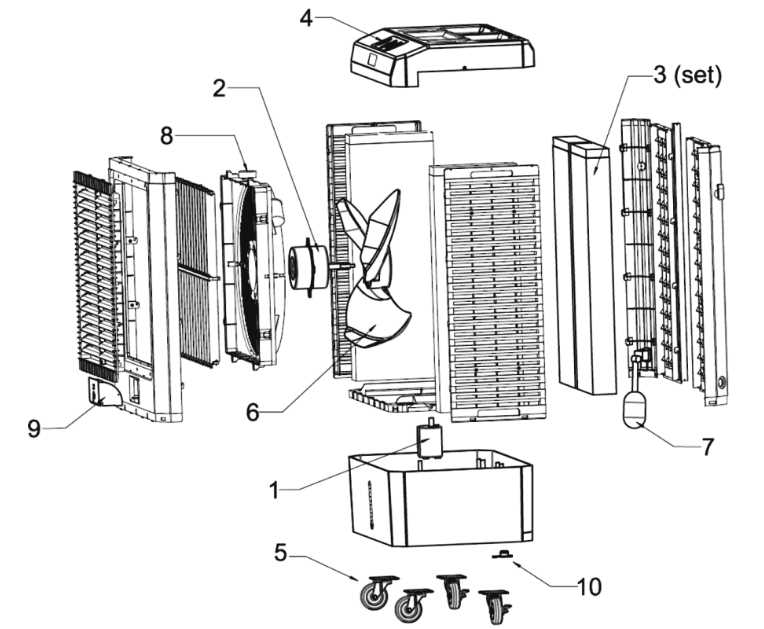

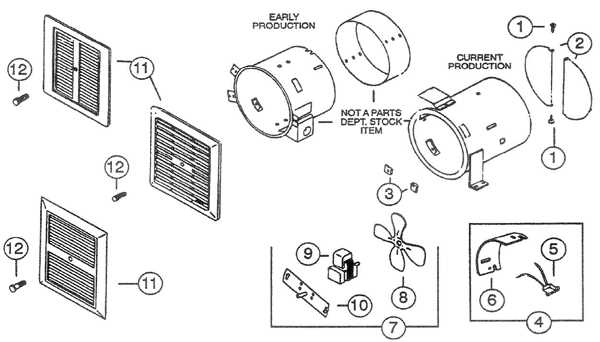

Understanding technical drawings is an essential skill when it comes to repairing or maintaining any complex system. These visual representations provide a clear overview of how different components fit together and how they function within the entire unit. Properly interpreting these diagrams allows users to identify parts, troubleshoot issues, and carry out repairs more effectively.

When examining a technical drawing, the first step is to familiarize yourself with the symbols and labels used. Each part is typically represented by a unique symbol or shape, and these symbols are often accompanied by numbers or letters that correspond to specific components. It’s important to carefully follow the lines connecting these symbols, as they indicate how parts interact or connect within the system.

Another crucial element to understand is the orientation of the diagram. The placement of components may vary depending on the view or perspective of the drawing. Diagrams often show a top-down, side, or exploded view of the system to give a comprehensive look at its structure. Paying attention to the direction of airflow and fluid movement can also provide valuable insights into the operation of the system.

Common Issues with Evaporative Cooler Parts

Like any mechanical system, temperature control devices can experience issues due to wear, lack of maintenance, or improper operation. Identifying these problems early can save both time and money by preventing further damage. Common issues often involve specific components that affect the system’s overall performance.

One of the most frequent problems is clogging or degradation of filters. Over time, these components accumulate dust, debris, and moisture, reducing airflow and efficiency. A clogged filter can lead to overheating, inadequate cooling, or even system failure. Regular cleaning and replacement are necessary to maintain optimal performance.

Another common issue is with the fan or motor. If these components fail or become worn out, it can lead to weak airflow, causing the system to struggle in delivering the desired cooling effect. In many cases, a noisy or malfunctioning motor indicates internal wear or a need for lubrication. Timely attention to these components can prevent complete breakdowns.