When it comes to maintaining your lawn care equipment, a clear understanding of its core components is essential. Knowing the individual parts and their functions helps you troubleshoot, repair, and optimize performance. This knowledge allows for more efficient maintenance and ensures the longevity of your equipment.

Each machine is built with numerous elements working together to achieve seamless operation. Understanding how these components interact can prevent common issues and improve overall efficiency. Whether you’re a professional landscaper or a home gardener, familiarizing yourself with the layout of the system is an invaluable skill.

Proper care and awareness of each section can greatly reduce wear and tear, minimizing the need for expensive repairs. Taking time to learn about the construction and maintenance processes is a wise investment for anyone relying on lawn equipment regularly.

Exmark Lazer Z 60 Parts Overview

In any high-performance lawn care machine, understanding the core components is vital for efficient operation. Each section plays a crucial role in ensuring smooth functionality, and knowing how these elements fit together can help with maintenance and repairs. This overview will focus on the primary components, highlighting their importance and how they contribute to the overall system.

Key Functional Elements

The primary features of the system include the engine, transmission, and steering mechanisms, all working together to provide power and control. The engine serves as the heart, driving the system, while the transmission controls the movement. Steering components ensure precision in maneuverability, allowing for accurate cutting and overall ease of use.

Supporting Components and Structure

Supporting elements such as the frame, wheels, and control systems provide stability and enhance maneuverability. The frame offers structural integrity, while the wheels ensure smooth movement across various terrains. Control systems, often featuring levers and pedals, allow the operator to guide the equipment with precision, enhancing user experience and functionality.

Key Components of the Lazer Z 60

Understanding the main elements of any lawn care machine is essential for effective maintenance and operation. These key components work together to provide optimal performance, ensuring the equipment functions at its best. By knowing what each section does, operators can identify potential issues and take proactive steps to maintain the system.

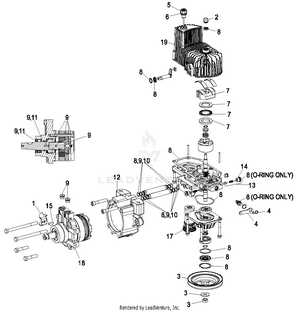

Engine and Transmission

The engine is the driving force behind the system, converting fuel into mechanical energy to power the machine. Coupled with the transmission, it controls speed and direction, making the equipment responsive to operator commands. Regular maintenance of both components ensures that the machine performs efficiently and lasts longer.

Steering and Control Mechanisms

Steering mechanisms are essential for maneuverability, allowing the operator to guide the equipment precisely. The control systems, often featuring pedals or levers, ensure smooth and responsive handling. A well-functioning control system enhances the ease of operation, making the machine easier to use and more effective in navigating various terrains.

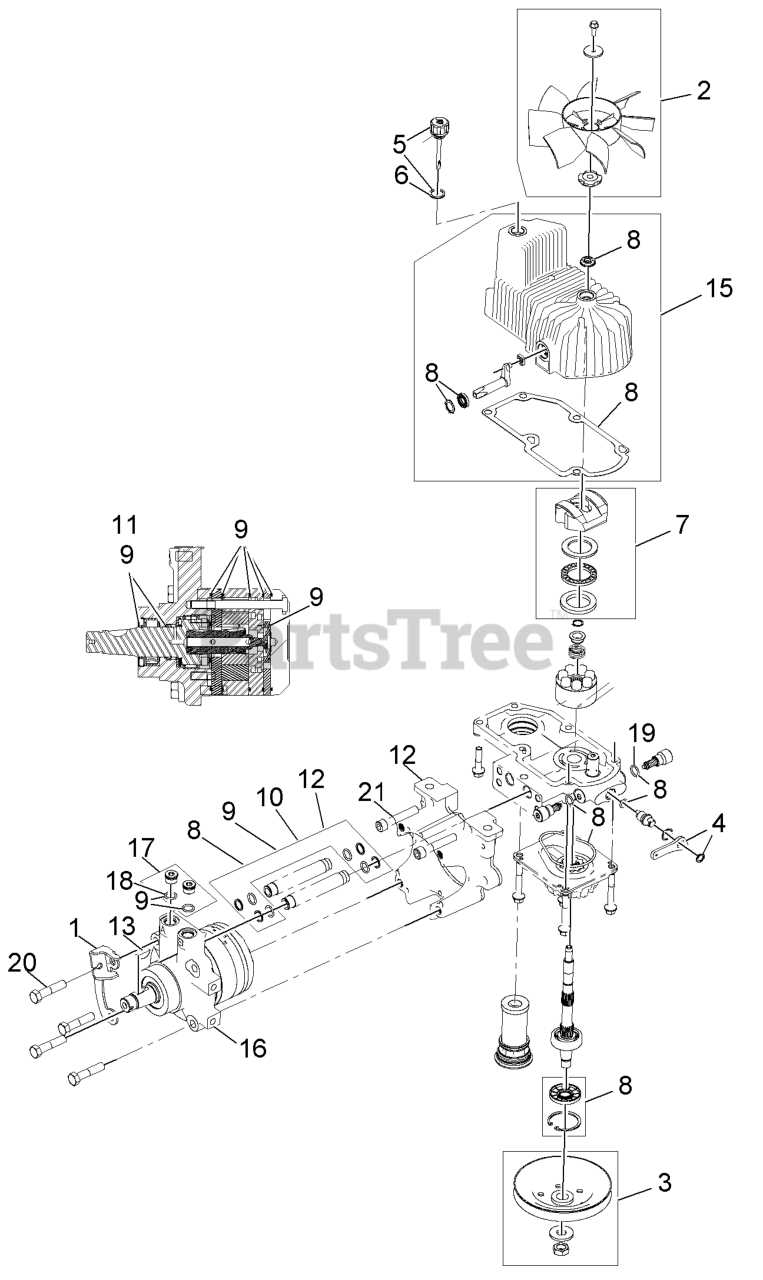

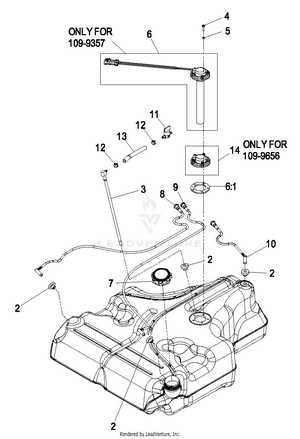

Understanding the Assembly Diagram

Having a clear understanding of how the various components of a machine fit together is essential for maintenance and troubleshooting. An assembly layout serves as a visual guide, showing the relationship between the different parts and how they work in unison. This knowledge helps operators and technicians identify any issues, plan repairs, and carry out maintenance efficiently.

Interconnecting Components

The assembly layout provides a visual representation of how individual sections are connected. From the engine to the control systems, understanding these linkages allows for more precise maintenance. It’s crucial to know how parts interact to prevent damage or malfunction, especially when working with complex systems.

Efficiency in Repair and Maintenance

By studying the assembly structure, operators can quickly locate any damaged or worn-out components. Knowing the exact positioning and arrangement of each part makes the repair process more efficient, reducing downtime and keeping the equipment running smoothly. Proper knowledge of the assembly also ensures that replacements are made accurately, preserving the functionality of the entire system.