When it comes to maintaining and repairing outdoor machinery, understanding the internal structure is essential. Knowing how each component works together can significantly enhance the efficiency of your equipment. A clear visual representation of the system’s individual parts is invaluable for both troubleshooting and routine upkeep.

Efficient maintenance relies on familiarity with the various components and their functions. By visualizing how each element interacts within the system, users can address problems more effectively, reduce downtime, and improve the longevity of their equipment.

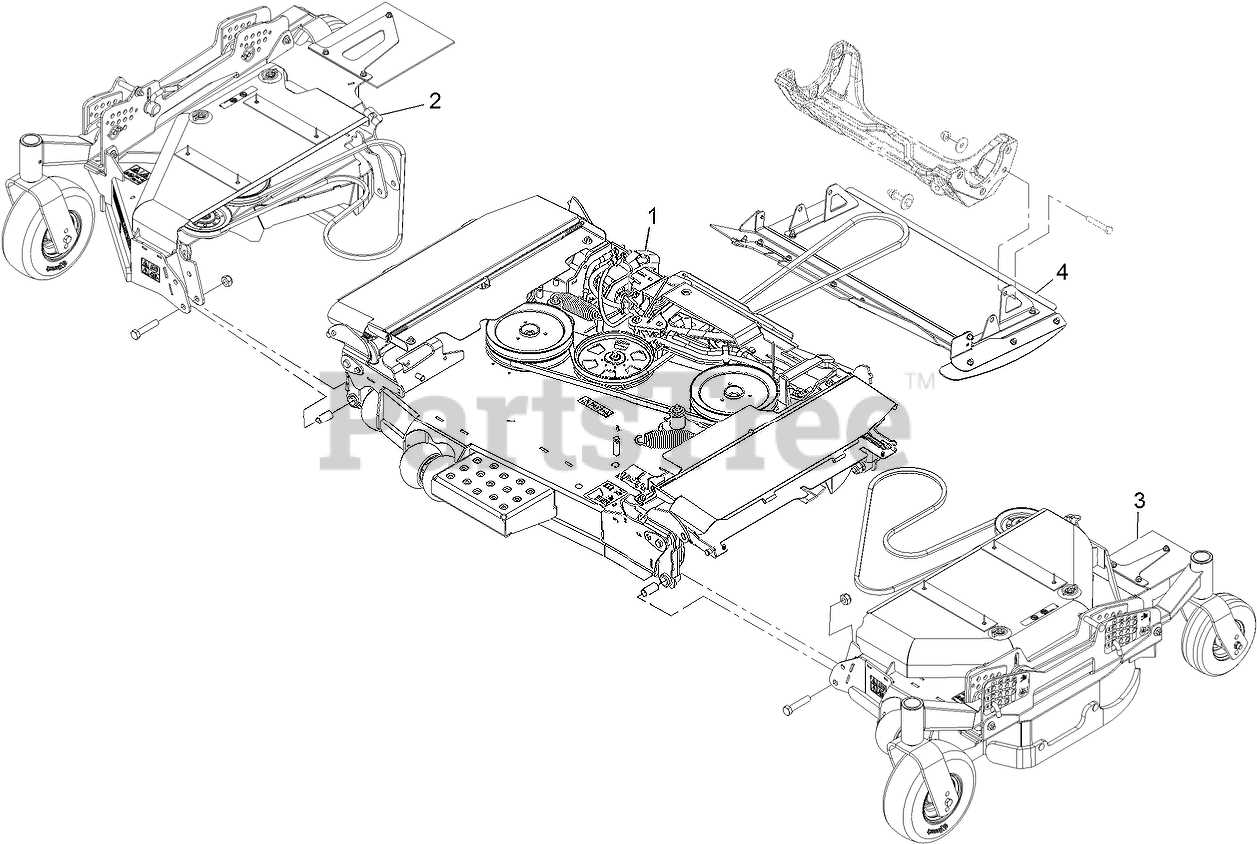

Accurate mapping helps identify the exact location of every essential piece, ensuring that users can easily spot issues such as wear or damage. This organized approach makes it simpler to find replacement parts and perform necessary repairs with precision.

Understanding Lawn Equipment Components

The internal structure of any outdoor machine consists of multiple interconnected elements, each playing a vital role in its operation. Familiarizing yourself with these components is essential for effective maintenance and troubleshooting. Every part works together to ensure smooth performance, and understanding their function can help avoid costly repairs and downtime.

Key Elements and Their Functions

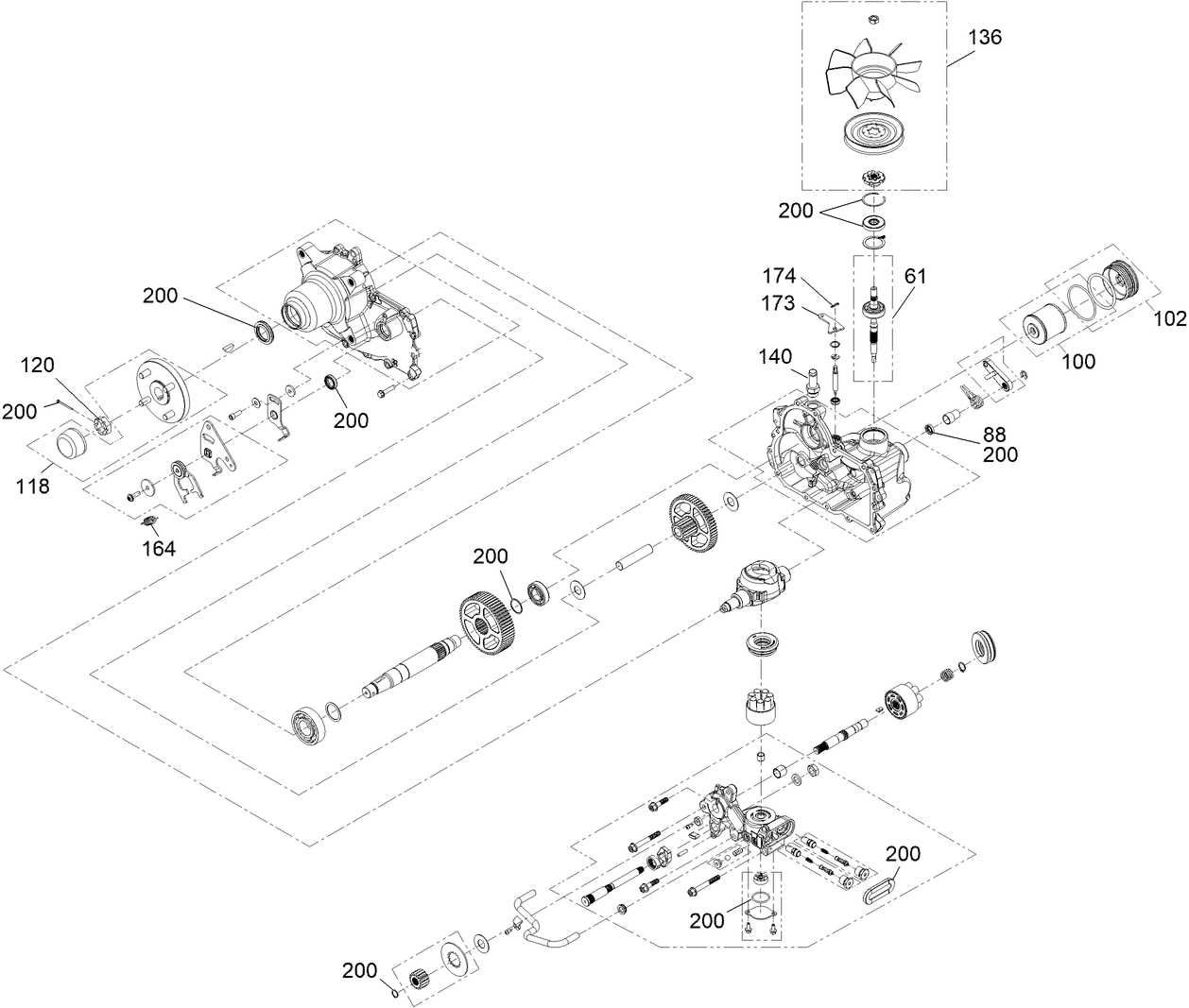

The core functionality of the equipment depends on critical components such as the engine, transmission, and control systems. The engine powers the entire system, while the transmission enables the transfer of energy. Additionally, the control system allows operators to adjust settings and manage the operation efficiently.

Common Issues and Their Impact

While each element is crucial for optimal performance, wear and tear can lead to issues over time. Understanding how to recognize early signs of damage or malfunction can help prevent further complications. Regular inspections of the key components ensure that any necessary repairs are made promptly, maintaining the overall functionality of the machine.

Identifying Key Elements for Maintenance

Regular upkeep of outdoor machinery requires a solid understanding of its main components. Recognizing the critical parts that require routine inspection or replacement can help maintain optimal performance. Effective maintenance prevents unexpected breakdowns and extends the lifespan of the equipment.

Essential Components to Inspect

Among the most vital elements to check regularly are the engine, blades, and drive system. The engine is responsible for power generation, making it crucial to monitor for any signs of wear or overheating. The blades need to be sharp and free from damage, as they directly impact cutting efficiency. The drive system, which includes belts and wheels, ensures smooth movement and proper traction.

Preventive Measures for Longevity

Routine inspections should focus on these key components to detect potential issues before they become serious problems. Keeping the engine clean, changing filters regularly, and ensuring all moving parts are properly lubricated can go a long way in preventing costly repairs. Replacing worn-out elements promptly ensures the machinery continues to perform effectively.

Benefits of Using a Component Breakdown

Utilizing a clear visual representation of a machine’s internal structure offers several advantages, particularly when it comes to maintenance and repair. It serves as a comprehensive guide that helps users locate and identify each crucial element, ensuring that the right steps are taken during upkeep. With this type of reference, understanding the overall system becomes easier and more efficient.

One of the main benefits is the ability to pinpoint exact locations of components, which simplifies the troubleshooting process. When problems arise, having a detailed map allows for quicker identification of the affected area, reducing the time spent diagnosing issues. Additionally, knowing where each element is located helps with accurate replacement and ensures compatibility with new components.

Another significant advantage is the enhanced precision in assembling or disassembling equipment. With a visual aid, users can be confident they are handling parts correctly, which minimizes the risk of errors during repairs or maintenance tasks. This leads to fewer mistakes, longer-lasting equipment, and a smoother overall maintenance experience.