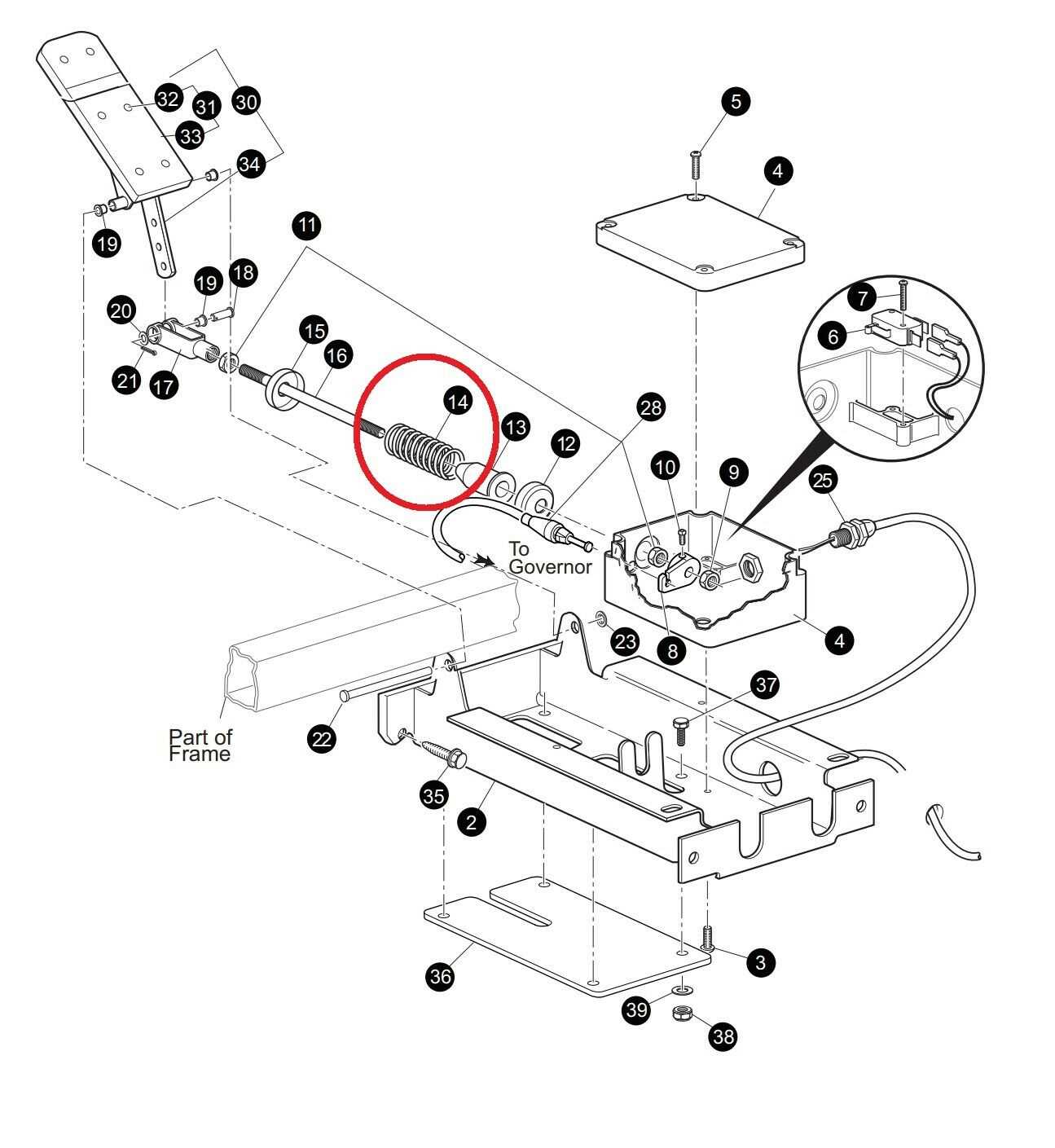

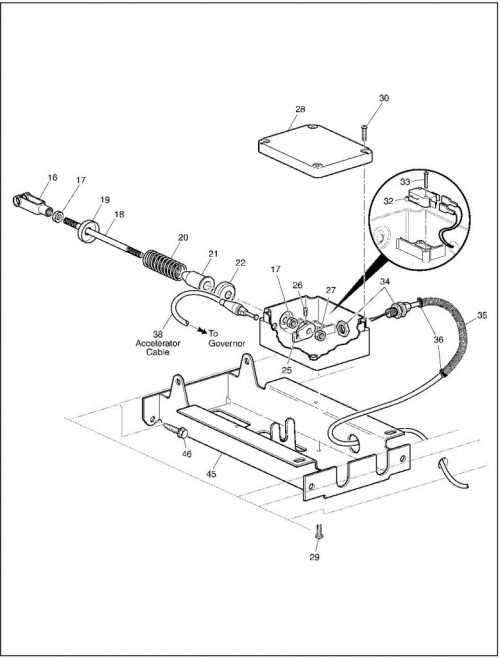

Understanding the structure of your vehicle is essential for efficient maintenance and troubleshooting. A detailed overview of its components allows for quicker identification of issues and effective solutions. With the right visual guide, it becomes easier to pinpoint specific parts and their functions within the system.

The layout of various mechanical elements plays a crucial role in simplifying repair processes. A well-organized reference can save time and effort, enabling even novice technicians to locate necessary components with ease. Knowing where each element is situated is key to ensuring smooth operations and extending the life of your vehicle.

By using a clear and accurate reference guide, you can approach maintenance with confidence. This organized approach leads to better decision-making during repairs, ensuring that you address the root cause of issues rather than just symptoms.

Understanding Vehicle Component Layout

A clear and structured view of your vehicle’s layout is essential for effective maintenance and repair. By understanding where each element is positioned and how it interacts with other components, you can streamline troubleshooting and reduce the time spent locating issues. A well-organized layout enables a systematic approach to fixing and improving your vehicle.

Locating Key Components for Maintenance

Knowing the location of key elements within the system is vital. Whether you’re dealing with the engine, suspension, or electrical systems, each part has a specific role that contributes to the vehicle’s overall performance. By studying the layout, you can identify parts that need attention more efficiently, preventing unnecessary disassembly and saving valuable time.

Importance of an Organized Overview

An organized overview provides more than just convenience; it offers a significant advantage in terms of accuracy during repairs. With the right visual aid, mechanics can immediately focus on the area of concern without second-guessing. This precision leads to more reliable fixes and less downtime, ensuring your vehicle stays in optimal condition.

Key Components of Utility Vehicle Models

To maintain peak performance, it’s important to understand the critical elements that make up the structure of a utility vehicle. These components, each serving a specific function, work in unison to ensure smooth operation. By gaining familiarity with their roles and locations, you can more effectively manage maintenance and repairs.

Engine and Transmission Systems

The engine is the heart of the vehicle, responsible for powering all operations. Paired with the transmission system, it converts energy into motion, ensuring that the vehicle moves efficiently. A solid understanding of these key systems will help you diagnose performance issues and plan for necessary repairs or upgrades.

Suspension and Steering Mechanisms

For a smooth ride and precise control, the suspension and steering systems are essential. The suspension absorbs shocks, ensuring comfort on uneven terrain, while the steering mechanism allows for responsive handling. Proper maintenance of these components ensures both safety and comfort during operation, and their locations within the vehicle can be easily pinpointed with the right reference.

How to Use the Component Layout for Repairs

Having a detailed guide of the vehicle’s internal structure is crucial for efficient repairs. By referring to a well-organized layout, you can easily locate the troubled parts and address specific issues without unnecessary steps. This reference tool simplifies the process, helping you tackle problems with precision and speed.

Identifying Faulty Elements

When a malfunction occurs, the first step is to identify which system or component is at fault. A comprehensive reference allows you to pinpoint areas that may require attention. By following the visual guide, you can quickly locate the malfunctioning part and determine if it needs to be repaired or replaced.

Planning the Repair Process

Once you’ve identified the problematic components, the next step is to plan the repair. Understanding the surrounding systems and how they interact helps in avoiding unnecessary disassembly. With the right reference, you can focus on only the required sections, making the repair process more efficient and less time-consuming.