When working with farm equipment, having a clear understanding of its individual components is crucial for proper maintenance and functionality. Each machine is built with several essential parts that work together to ensure optimal performance. Knowing how these elements interact can save time and reduce costly repairs.

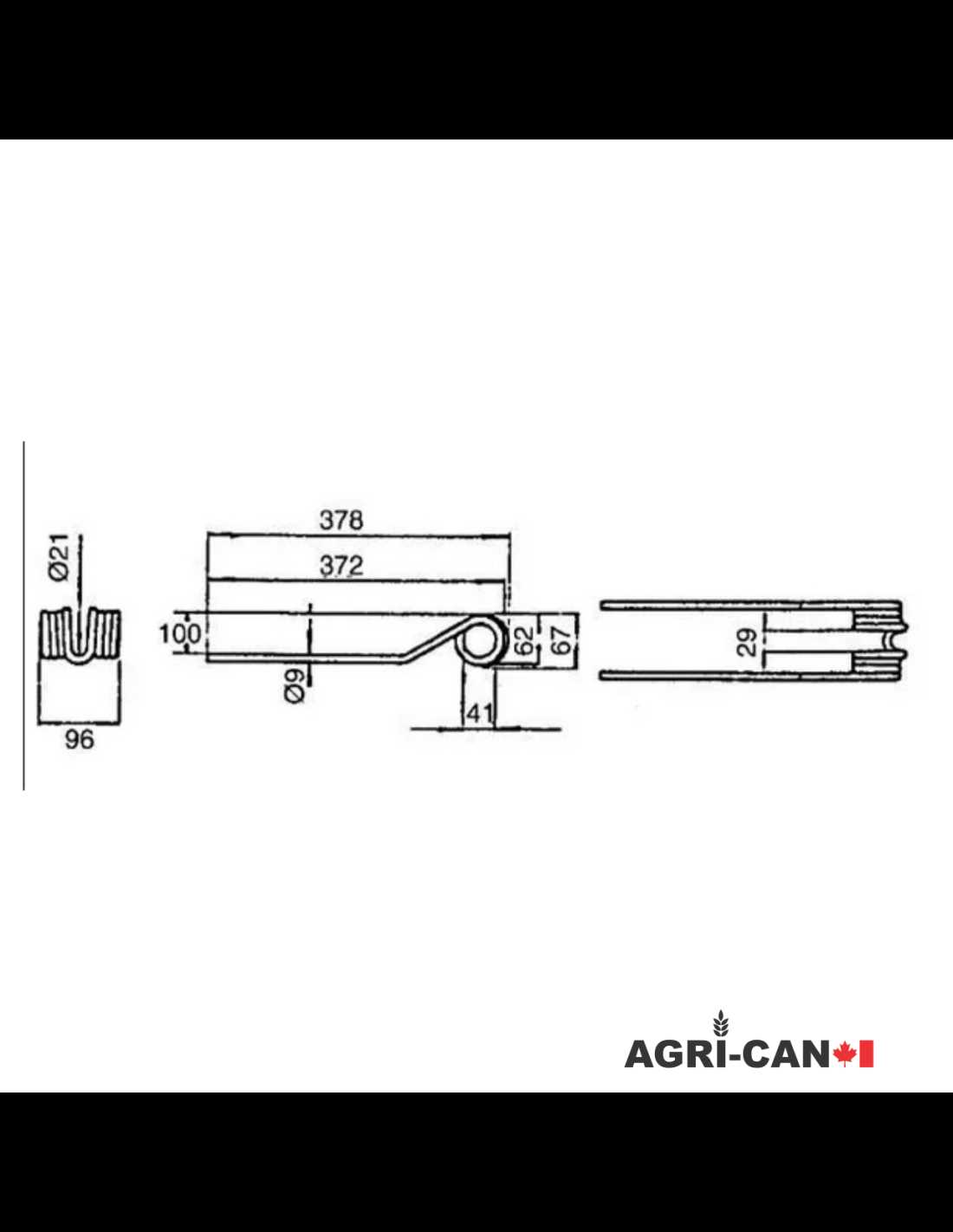

Detailed illustrations and breakdowns are often used to highlight the specific functions and connections between the various components. By referring to these visual guides, operators can gain a better understanding of their equipment, identify worn-out or damaged parts, and perform repairs more efficiently.

Having easy access to such resources helps in troubleshooting issues quickly. Proactive maintenance becomes much easier when you are familiar with the inner workings of your machine, enabling you to prevent malfunctions before they disrupt operations.

Overview of Agricultural Equipment Components

When it comes to maintaining farm machinery, understanding the key components that drive its operation is essential. These elements work in unison to perform specific tasks and ensure smooth functionality during use. Familiarizing yourself with each section and its role can enhance both performance and durability.

The equipment is designed with various interconnected sections, each fulfilling a unique purpose. These parts range from the frame and gearbox to the rotating elements and drive mechanisms. Their proper alignment and maintenance are crucial for avoiding downtime and enhancing the longevity of the machinery.

Key Mechanical Elements

At the heart of the system are the mechanical components that transmit power and facilitate movement. Gear systems and rotors are some of the most important elements that need to be regularly checked for wear. Proper lubrication and timely replacements keep these mechanical parts running efficiently.

Hydraulic and Electrical Systems

In addition to the mechanical features, hydraulic and electrical systems play a significant role in the overall operation. These systems control various functions, such as adjusting height or speed, and ensure precision in the machine’s performance. Regular inspections of hoses, valves, and electrical wiring are necessary to avoid unexpected failures.

Understanding Key Components of the Equipment

To fully appreciate how agricultural machinery functions, it is important to recognize the essential elements that make up the machine. Each component serves a distinct role, contributing to the overall performance. By understanding the purpose of each part, operators can perform efficient maintenance and troubleshooting when necessary.

Key components are often grouped based on their function and their role in the operation of the machine. Below are some of the most significant elements that work together:

- Frame and Structure: Provides the foundation and support for all other components.

- Rotating Mechanisms: Includes the parts responsible for the motion, such as gears and drive shafts.

- Power Transmission: This system ensures that the energy generated is effectively transferred to the working parts of the machine.

Each of these sections interacts with others to create seamless functionality. Regular checks on these key parts help maintain high efficiency and prevent unnecessary downtime during operations.

Additionally, the hydraulic and electrical systems contribute to the precision and versatility of the machinery, adjusting settings such as height and speed to adapt to different tasks. Understanding these components is crucial for achieving optimal performance.

How to Use the Parts Breakdown

Having access to a detailed breakdown of a machine’s components can be incredibly helpful for performing maintenance and repairs. These visual guides serve as maps, helping operators locate specific sections and identify individual components that need attention. Knowing how to navigate and interpret these resources ensures accurate repairs and efficient troubleshooting.

Step-by-Step Guide for Navigating the Breakdown

Start by familiarizing yourself with the overall layout of the guide. The breakdown will usually be divided into sections, each dedicated to a particular part of the machine. Focus on the area that needs attention, and identify the components by their labels and numbers. This will help you pinpoint the exact piece that requires replacement or servicing.

Using the Breakdown for Repairs

Once you have located the necessary component, refer to the guide for instructions on how to remove, replace, or repair it. Pay attention to any specific maintenance tips that may be included, such as lubrication requirements or special tools needed. Following these directions carefully ensures the work is done correctly, preventing further issues in the future.

Step-by-Step Guide for Maintenance

Proper maintenance is crucial for ensuring the longevity and efficient performance of any machine. Following a systematic approach allows operators to address potential issues before they become major problems. This guide will walk you through the essential steps to keep your equipment in top working condition.

Start by performing regular inspections. Check all moving parts, gears, and mechanisms for signs of wear or damage. Make sure that all connections are tight and secure, as loose parts can cause malfunction. Lubricating the necessary sections helps maintain smooth operation and prevents unnecessary friction.

Next, replace any worn or damaged components. Regularly replacing critical parts like bearings, belts, or seals can prevent more serious issues from occurring down the line. Make sure to use the correct replacement parts to avoid compatibility problems.

Lastly, clean the equipment thoroughly. Dust, dirt, and debris can affect the machine’s performance, so ensure that all areas are free from contaminants. A clean machine not only operates more efficiently but also reduces the likelihood of damage to sensitive parts.

Common Issues and Troubleshooting Tips

Even with regular maintenance, machines can experience occasional issues that may impact performance. Identifying and addressing these problems promptly can prevent further damage and minimize downtime. This section covers some common problems and offers troubleshooting advice to help resolve them efficiently.

One frequent issue is uneven operation or noise during use. This could be caused by misaligned or worn-out moving parts. Start by checking the alignment of the drive components and ensure everything is securely fastened. If the noise persists, inspect the gears or bearings for wear and replace them as needed.

Another common problem is reduced efficiency or slower operation. This may be due to insufficient lubrication or dirt buildup. Make sure that all moving parts are properly lubricated and clear of debris. If necessary, clean or replace filters and ensure that the hydraulic system is functioning correctly.

Lastly, electrical or hydraulic failures can occasionally occur. If you notice irregular operation or failure to respond, inspect the wiring for any loose connections or visible damage. For hydraulic issues, check for leaks or low fluid levels and address them promptly to avoid system failure.