In any mechanical system, knowing the layout and individual elements of a valve is crucial for efficient operation and maintenance. Whether you’re repairing or upgrading a water control system, familiarizing yourself with each piece ensures you can troubleshoot effectively and extend the life of your equipment.

Proper identification of each element in a valve assembly is the first step toward a successful repair or installation process. A clear understanding of how the components interact with one another helps professionals and DIY enthusiasts alike to approach challenges with confidence.

By breaking down the structure into its key parts, you can easily identify wear points, potential failures, and opportunities for improvement. This guide will provide you with a detailed look at the components involved, offering valuable insights for anyone working with water regulation systems.

Understanding the Febco 765 1 Valve

Every valve is an essential part of a water management system, controlling the flow and pressure within pipes. A well-designed valve ensures optimal operation and prevents unnecessary failures that can disrupt the system’s performance. To maintain and troubleshoot these devices effectively, it’s important to understand the functionality and relationship between their individual components.

Basic Functionality and Purpose

A valve is designed to regulate or stop the flow of liquids or gases in a controlled manner. The role of each part, whether it’s a sealing mechanism or a pressure-regulating component, contributes to the overall efficiency and reliability of the system. For optimal functioning, all parts must be in good condition and working harmoniously together, which is why knowing their individual roles is so important.

Common Features and Mechanisms

Most valves consist of similar components, including a body, diaphragm, spring, and a control mechanism. These parts work together to ensure smooth flow regulation and pressure maintenance. Understanding how these components interact will give you a clearer picture of the system as a whole, and assist in identifying potential issues, such as leaks or wear, that may impact the valve’s performance.

Key Components of the Febco 765 1 Diagram

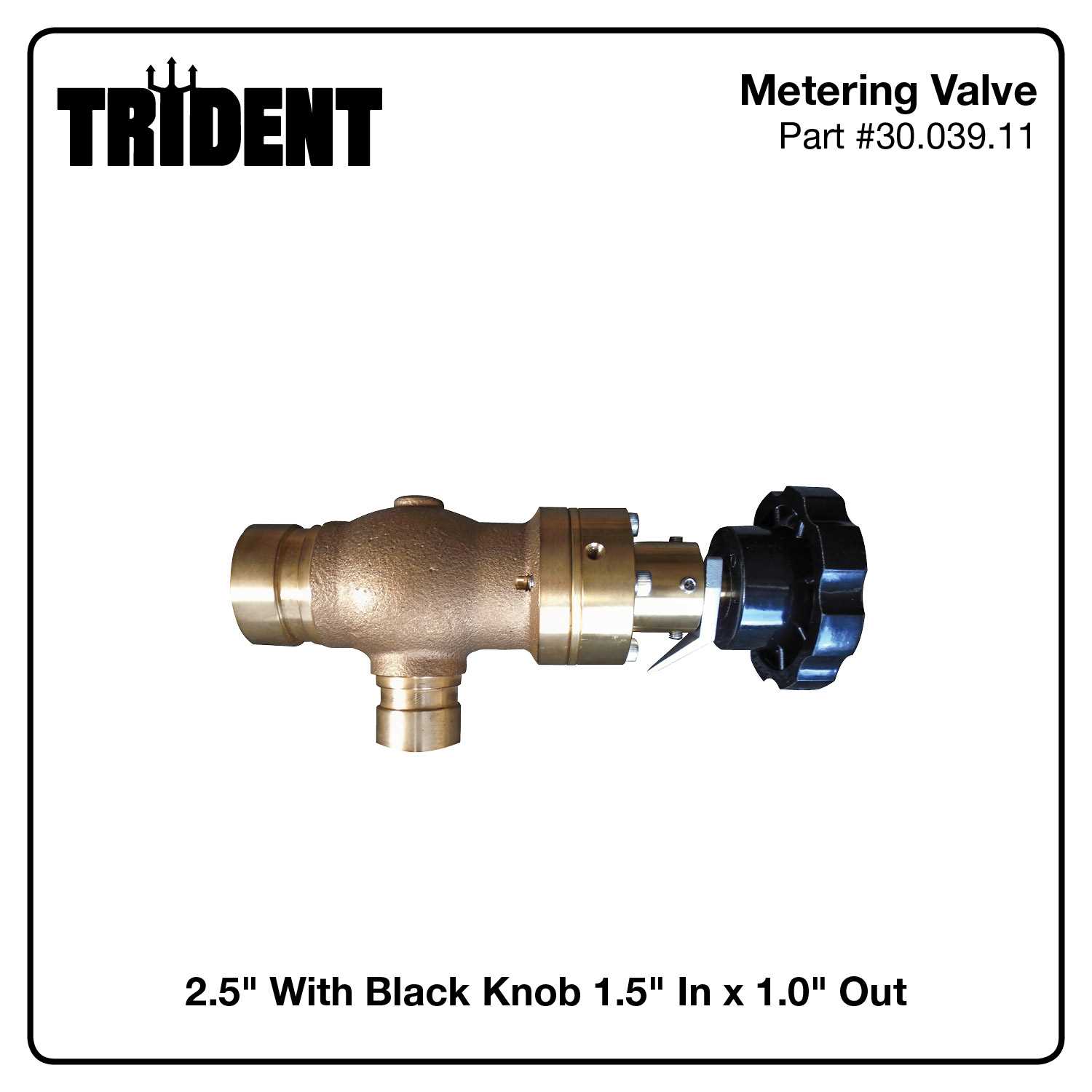

To fully grasp how a valve operates, it’s essential to understand the key elements that make up its structure. Each component plays a specific role in regulating flow, ensuring efficiency, and preventing leaks. Identifying these parts is the first step toward a more effective maintenance and repair strategy.

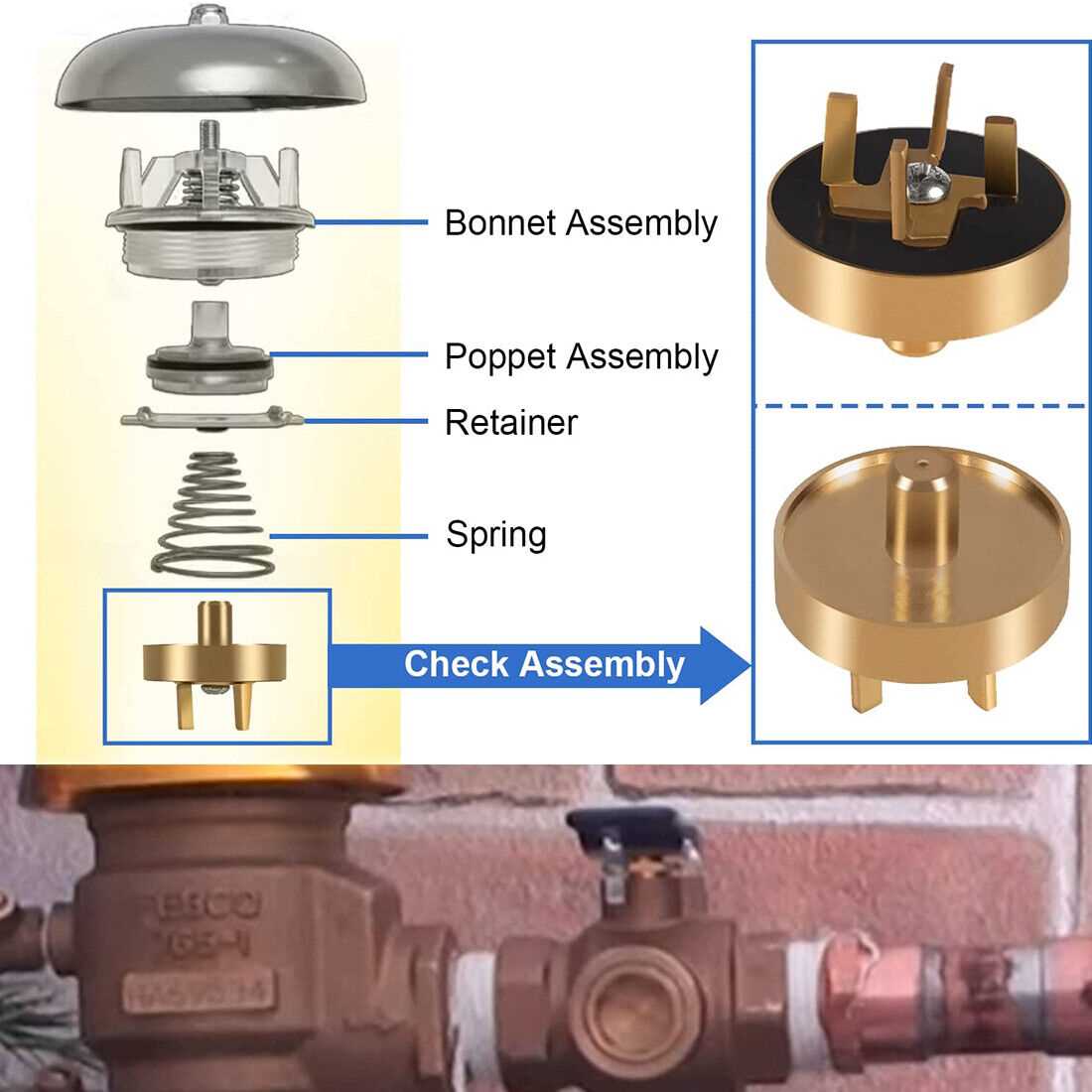

Typically, the valve consists of several crucial parts, such as the body, diaphragm, spring, and sealing elements. These components work together to control the movement of fluids and gases through the system, providing both functionality and durability. By familiarizing yourself with these individual elements, you can better identify issues that may arise during usage or maintenance.

The body of the valve serves as the main structure, housing other parts and providing the framework for operation. The diaphragm often serves as a flexible barrier to control fluid flow, while the spring regulates pressure, ensuring smooth operation. Additionally, the sealing components prevent leaks, maintaining system integrity over time.

How to Use the Febco 765 1 Parts Breakdown

Knowing how to read and utilize a detailed breakdown of a valve’s components can significantly enhance your ability to maintain and repair the system. This guide will walk you through the process of using a comprehensive diagram to identify parts, understand their functions, and address potential issues.

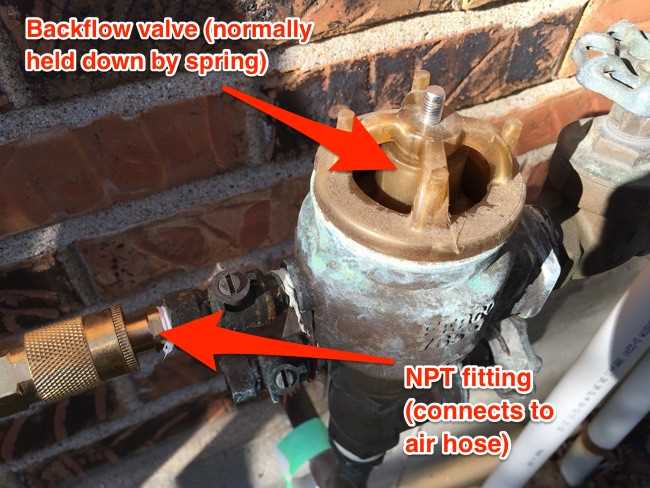

Step-by-Step Identification

The first step in using a parts breakdown is to familiarize yourself with the overall layout of the valve. By carefully studying the diagram, you can identify each component’s position within the assembly. Understanding the location of key elements such as the spring, diaphragm, and body will allow you to pinpoint where problems are likely to occur, saving time during troubleshooting and repairs.

Diagnosing Issues and Planning Repairs

Once you have identified the components, use the breakdown to cross-reference the symptoms of a malfunction with the parts shown. If a valve is leaking, for instance, focus on the sealing elements. If the flow is irregular, the issue may lie within the control mechanism. By using the diagram to direct your attention to specific parts, you can more effectively diagnose and address any issues.