Knowing the individual components of your device is essential for maintaining its performance and longevity. Understanding how each piece functions helps to troubleshoot problems and ensures proper care. Proper knowledge of the internal mechanisms can prevent unnecessary repairs and allow for efficient operation.

When any issue arises, identifying the specific component causing the malfunction is crucial. Having a clear picture of how each part interacts with the rest will help in diagnosing problems accurately. Knowing what each part does will enable you to determine whether it requires cleaning, adjustment, or replacement.

Whether you’re dealing with routine maintenance or unexpected failures, understanding your machine’s setup is a valuable skill. By familiarizing yourself with the components and how they work together, you can extend the lifespan of your device while ensuring it operates at peak efficiency.

Understanding Fellowes Shredder Components

Each device is made up of multiple elements that work in harmony to perform its intended function. By learning the roles of these different components, you can enhance the efficiency and reliability of the machine. Recognizing how these parts interconnect allows for easier identification of issues and quick solutions.

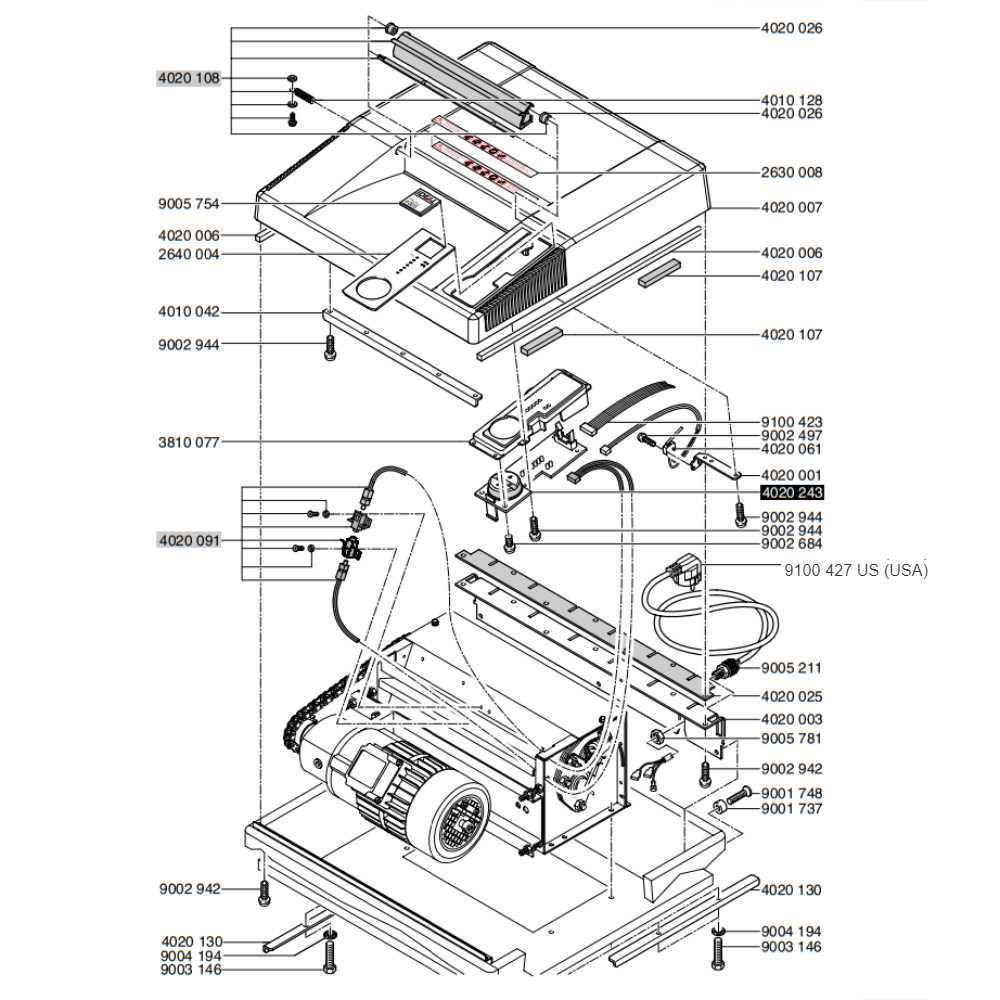

For optimal performance, it is important to understand the key sections of the device. These include the motor, cutting mechanism, feed opening, and waste collection area. Familiarizing yourself with each part ensures better maintenance and aids in diagnosing potential problems before they become critical.

In addition, understanding how the machine is assembled and how each piece interacts with the others can help with the disassembly and reassembly processes when needed. Proper care of these internal mechanisms allows for smoother operation and extends the lifespan of the equipment.

Identifying Parts in Your Fellowes Shredder

Understanding the key components of your device is the first step in diagnosing issues and performing maintenance. Recognizing each element and its function helps you identify potential problems and address them efficiently. When you are familiar with the layout and roles of the individual pieces, troubleshooting becomes much simpler.

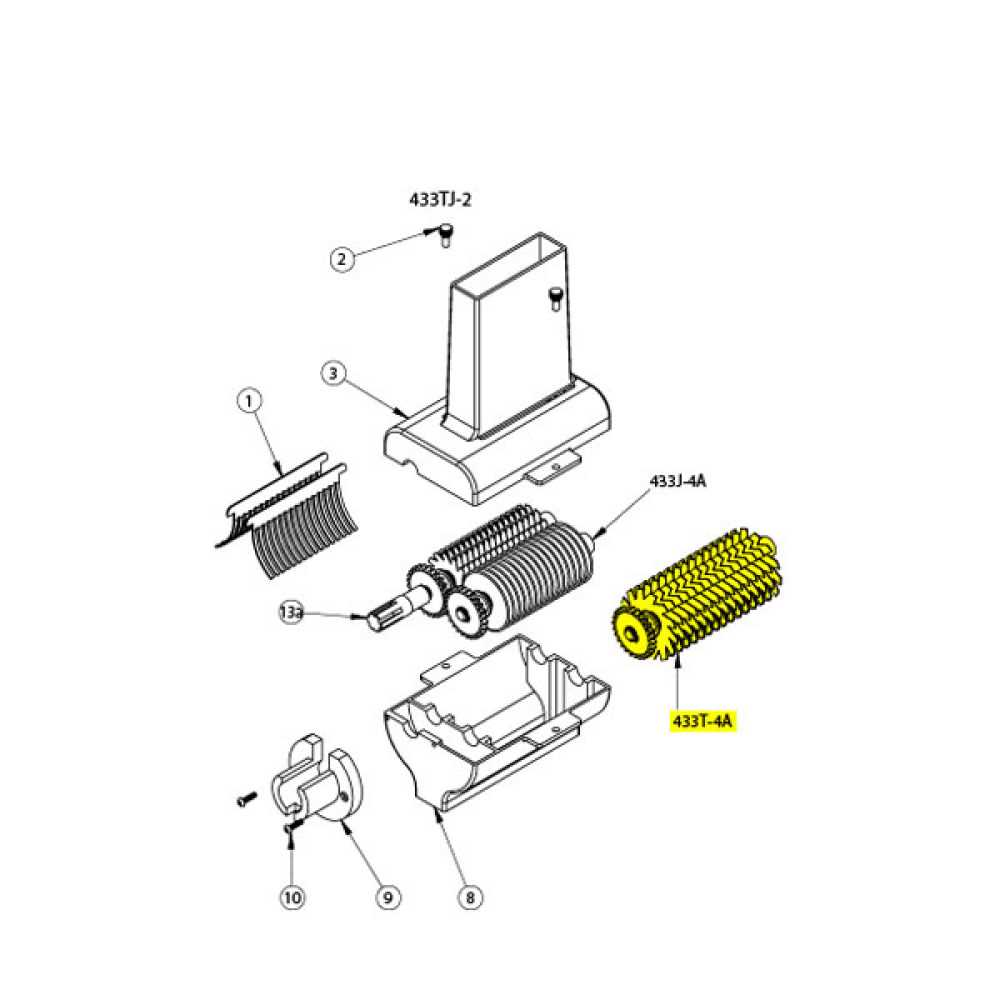

The central mechanism responsible for cutting and processing materials is a critical part of the device. It works in tandem with the motor, which powers the system. Alongside these core elements, you’ll find the feed entry, waste collection bin, and safety features, all contributing to smooth operation. Knowing the exact location and function of each part is essential for effective use and upkeep.

Each machine may have slight variations, but most devices share similar structures. Whether you’re replacing a worn part or performing routine cleaning, having a clear understanding of these components will make the task much more manageable. Regular checks ensure optimal performance and prevent unnecessary wear.

Common Issues and Solutions for Shredders

Like any mechanical device, your equipment may encounter issues over time that can affect its performance. Recognizing these problems early and knowing how to address them is key to keeping the machine functioning smoothly. Some of the most common issues can be easily fixed with basic knowledge and simple maintenance practices.

One common issue is jamming. This often happens when the machine is overloaded or if foreign objects are fed into it. To resolve this, turn off the device, remove the paper or object causing the blockage, and ensure the feed is clear. Regularly cleaning the feed entry can prevent this problem.

Another frequent problem is overheating. This can occur when the device is used for extended periods or when the motor is overworked. To avoid overheating, make sure to give the machine a break after heavy use and avoid running it continuously. Proper ventilation is also essential for cooling the internal components.

Lastly, dull cutting mechanisms can reduce the effectiveness of the machine. If your device is no longer cutting efficiently, it may be time to clean or replace the cutting mechanism. Keeping these components free of debris will help maintain optimal performance.