Proper maintenance of lawn machinery requires a clear understanding of its individual elements. Knowing how each part functions and fits together is essential for smooth operation and effective repairs. With a solid grasp of these components, you can ensure longevity and avoid common mechanical issues.

In this section, we will explore the key aspects of reading equipment layouts, helping you identify critical parts and their roles. By familiarizing yourself with these visual guides, you will be better equipped to handle maintenance tasks and troubleshooting without confusion.

Regular inspection of machinery parts is crucial for early detection of wear and tear. Identifying problems early can save time and money on costly repairs. Understanding how each piece contributes to overall performance will allow you to spot irregularities more efficiently.

Understanding Lawn Equipment Components

Every piece of machinery relies on a network of interconnected elements that work together to ensure optimal performance. Recognizing how these components function and interact is fundamental for maintaining smooth operation. By familiarizing yourself with each crucial part, you gain the ability to handle repairs and prevent malfunctions before they escalate.

The key to efficient maintenance lies in knowing the individual roles of each element within the system. For instance, drive mechanisms, cutting systems, and control units all play vital roles in the machine’s overall functionality. A comprehensive understanding of these units allows for quicker diagnosis and precise adjustments during service.

Engine components are at the heart of any machine’s operation, while structural elements ensure the stability and safety of the entire unit. Additionally, electrical systems control various functions, making it crucial to recognize their importance in maintaining functionality. When you can identify and understand each of these sections, your ability to troubleshoot issues will significantly improve.

How to Read the Equipment Layout

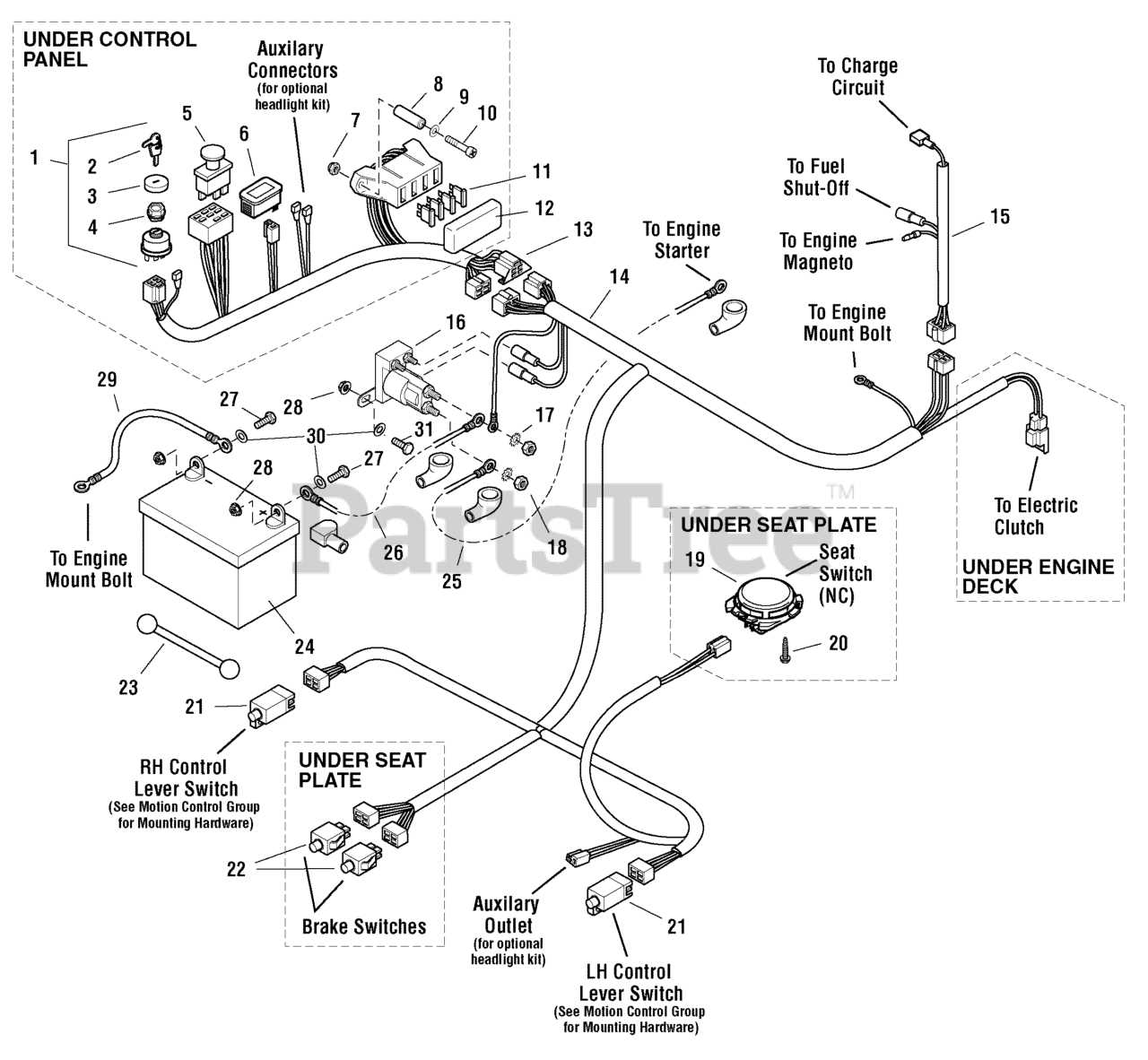

Interpreting a schematic layout requires a clear understanding of how the various components are represented and how they interact with one another. These visual aids are designed to simplify the identification of each element, helping you locate and understand their functions within the machinery. Knowing how to read these diagrams can make troubleshooting and maintenance tasks much more manageable.

Identifying Key Symbols

In these layouts, each component is typically represented by a standard symbol or label. Recognizing these symbols is the first step to deciphering the diagram. For example, mechanical parts like the engine or transmission might be depicted with simple shapes, while electrical components may be marked with specific notations that indicate their connection points.

Following the Connections

Once you’ve identified the components, it’s important to understand how they are connected. Lines in the diagram usually represent physical or functional links between elements, such as wiring or mechanical connections. Following these lines carefully will help you see how energy, signals, or forces flow through the system, providing insights into the machine’s operation.

Common Maintenance Tips for Lawn Equipment

Regular upkeep of lawn machinery ensures its longevity and reliable performance. Performing simple maintenance tasks on a routine basis can prevent costly repairs and improve efficiency. By focusing on key areas, you can significantly extend the lifespan of the equipment and ensure it functions smoothly throughout the season.

Regular Engine Checks

The engine is the heart of any machine, and keeping it in top condition is essential for optimal performance. Regularly check the oil levels and replace the filter as needed. Ensure the spark plug is clean and properly gapped, and examine belts and hoses for wear. These steps will help maintain engine efficiency and prevent unexpected breakdowns.

Inspecting the Cutting Mechanism

Properly maintained cutting components are critical for achieving clean, efficient results. Frequently inspect the blades for sharpness and damage, and replace them when necessary. Keeping the cutting deck clean and free of debris also prevents blockages and ensures a more even cut. Adjusting the height settings and ensuring proper tension will enhance performance and reduce strain on the system.