The mechanism of a lifting device relies on a variety of components working in harmony. Each element plays a vital role in ensuring smooth operation, whether it’s for raising heavy objects or providing support during maintenance tasks. Knowing how these elements interact with each other is essential for proper usage and troubleshooting.

In this guide, we will explore the key components involved in the lifting process. By understanding their structure and function, users can gain insights into maintaining and repairing the equipment efficiently. Regular knowledge of how each part contributes to the overall function is crucial for both safety and longevity.

Proper maintenance of these essential components helps extend the life of the equipment and ensures safe operation during various tasks. When these elements are well-understood, the risk of failure decreases, leading to better performance and reliability.

Understanding Lifting Equipment Components

The proper functioning of a lifting tool is dependent on several interconnected elements. Each component plays a distinct role, ensuring that the entire system works effectively and safely. Understanding the function and design of these components is crucial for both effective use and long-term maintenance.

At the core of the system, the mechanism relies on a combination of structural and hydraulic elements that facilitate lifting and lowering. Recognizing how each individual piece contributes to the overall performance allows users to operate the device confidently and troubleshoot issues when they arise.

Familiarity with these components not only helps with the daily use of the equipment but also aids in identifying when maintenance or repairs are needed. Proper care of each part ensures that the lifting tool remains reliable and safe for prolonged use.

Key Parts of a Lifting Mechanism

Understanding the main elements of a lifting system is essential for both operation and maintenance. These components work together to create a stable and efficient process for raising heavy loads. Each part has a specific function, contributing to the overall performance and safety of the system.

Hydraulic Cylinder

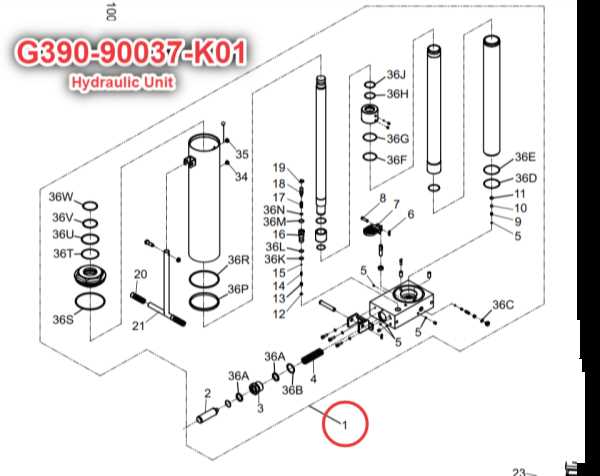

The hydraulic cylinder is a central part responsible for the lifting action. It uses hydraulic fluid to generate force, which is transferred to raise the load. The smooth movement of the cylinder is vital for ensuring consistent and reliable operation, allowing the mechanism to handle varying weights effectively.

Pump Mechanism

The pump mechanism is responsible for pushing hydraulic fluid into the cylinder. It plays a crucial role in building pressure within the system, which in turn enables the lifting action. Without a properly functioning pump, the entire lifting process would fail to work as intended.

Each of these components must work in harmony to ensure that the lifting device operates smoothly and safely. Regular maintenance and inspections of these key elements can help prevent breakdowns and ensure long-lasting performance.

How Lifting Mechanism Works

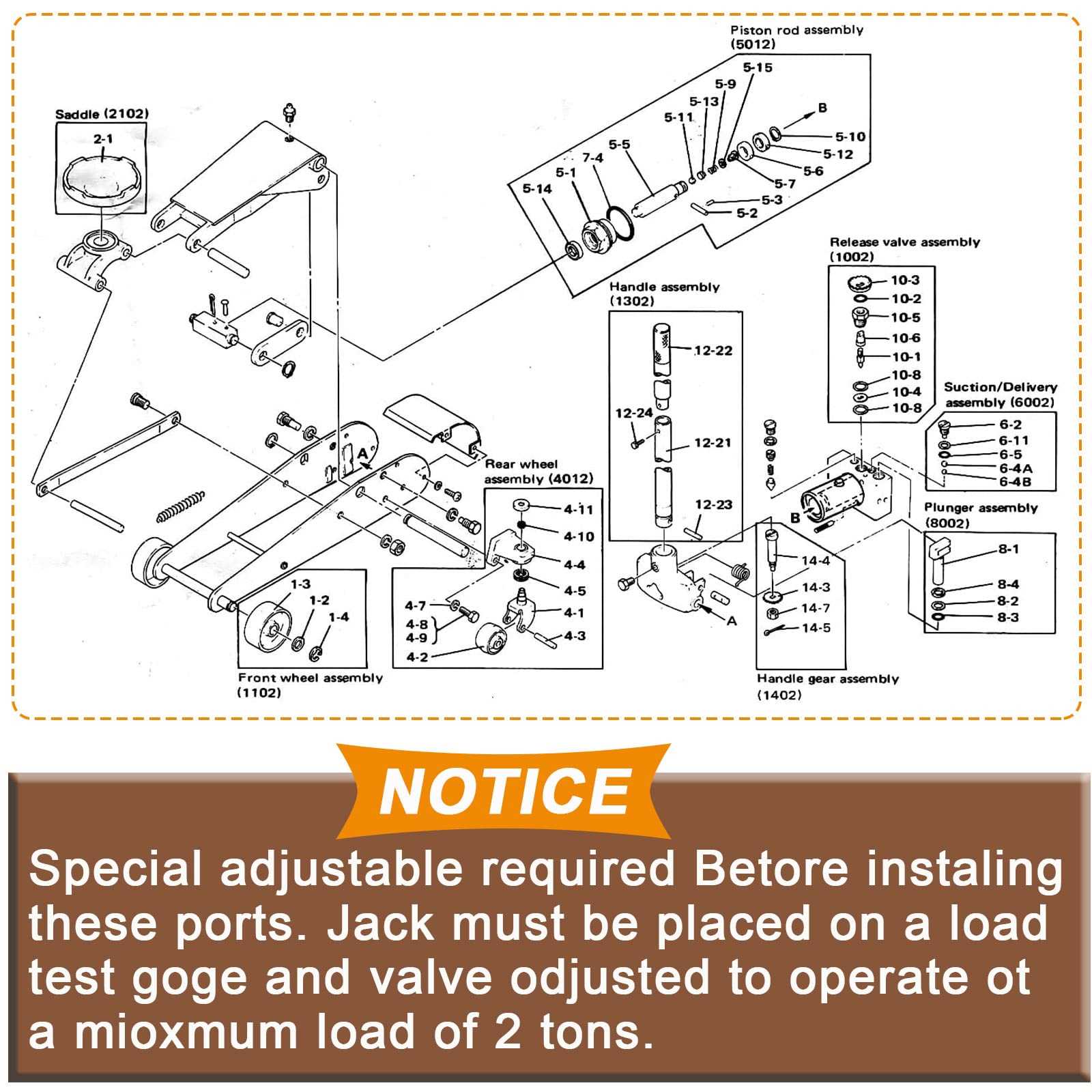

The operation of a lifting device involves a combination of hydraulic and mechanical systems working in sync. When the user operates the lever or pump, hydraulic fluid is moved through the system, creating pressure that lifts the load. This simple yet powerful process ensures smooth, efficient lifting even with heavy objects.

The key to this mechanism is the hydraulic cylinder, which relies on fluid pressure to raise or lower the platform. As the user pumps the handle, fluid flows into the cylinder, creating force that moves the load upward. Once the pressure is released, the weight is lowered back down, completing the cycle.

Precision in controlling the fluid flow is critical for the system’s reliability. The interaction between the pump, cylinder, and valves ensures that the process is both controlled and safe, allowing the equipment to lift various weights effectively.