In any industrial setting, machines designed to handle heavy loads rely on a complex system of interconnected elements. These essential components work together to provide stability, lifting capacity, and precision. Understanding how each part functions is crucial for ensuring safe operation and longevity of the equipment.

By studying the layout and functions of these systems, operators can gain valuable insights into how to maintain and troubleshoot these machines effectively. Proper knowledge of the structure allows for more efficient repairs, reduces downtime, and helps to avoid costly mistakes that could result from mismanagement.

Detailed understanding of each element’s role can significantly improve overall machine performance. Regular inspection and maintenance are vital to keep everything functioning smoothly, ensuring the equipment remains reliable for everyday tasks.

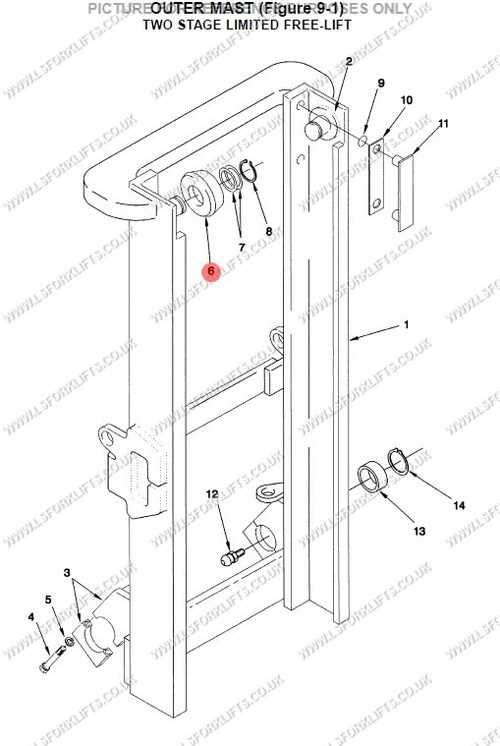

Understanding Forklift Mast Components

The lifting mechanism in industrial equipment is made up of a variety of critical elements that work in unison to enable the lifting and lowering of heavy loads. These components play a vital role in ensuring the machine operates efficiently and safely. A thorough understanding of how each piece contributes to the overall functionality can prevent mechanical failures and improve the machine’s performance.

Each element in the lifting system has a specific function, from providing structural support to ensuring smooth movement during operations. These components are often designed with durability in mind to withstand the constant stress of handling heavy weights. Understanding the role of each part allows operators to identify potential issues early and ensure regular maintenance is performed on time.

Regular inspection of these components is essential to maintain safe operations. Knowledge of how they interact helps in troubleshooting issues and performing repairs effectively. Whether adjusting tension or replacing worn-out pieces, being familiar with the system’s design is crucial for keeping the equipment in peak condition.

How to Identify Forklift Mast Parts

Identifying the various elements of a lifting system can seem challenging at first, but with a basic understanding of their functions and appearance, it becomes a much simpler task. These components are typically organized in a way that allows for easy recognition based on their shape, size, and placement within the mechanism. Knowing what each piece looks like and how it operates is key to effective maintenance and troubleshooting.

The main elements can often be distinguished by their role in the lifting process. For instance, some parts are responsible for providing stability, while others facilitate the upward and downward movement. Familiarizing yourself with the location and structure of these components is essential for quickly identifying them during inspections or repairs.

Once you have a clear understanding of each element’s purpose, recognizing signs of wear or damage becomes more straightforward. Regularly checking these components and understanding their function within the overall system can help you spot issues early, ensuring efficient operation and prolonging the equipment’s lifespan.

Importance of Mast Parts in Forklift Function

The components responsible for vertical lifting are essential for the smooth operation of material handling equipment. These elements work together to ensure the safe and efficient movement of heavy loads. Without properly functioning components, the machine’s performance can be compromised, leading to inefficiency and increased risk of failure.

Each part plays a crucial role in providing stability, control, and precision during lifting and lowering tasks. For example, certain components help distribute the weight of the load evenly, while others provide the necessary movement to raise or lower it smoothly. The effectiveness of the entire system depends on the proper functioning of each individual piece.

Neglecting these components can lead to significant operational issues, such as slow lifting speeds or even system malfunctions. Regular checks and maintenance are key to ensuring these elements remain in top condition, allowing the equipment to perform its tasks effectively and safely for an extended period of time.