Understanding the structure and functionality of essential machine elements is crucial for efficient maintenance and repair. A detailed layout helps users quickly identify and manage various parts, ensuring smooth operation and preventing potential issues. Whether you’re a novice or experienced technician, having access to a clear guide simplifies the troubleshooting process.

Effective organization of parts plays a pivotal role in both the assembly and repair stages. By breaking down complex mechanisms into easy-to-understand sections, users can save time and effort when addressing malfunctions or performing routine checks. This approach not only enhances user knowledge but also promotes safer handling and longevity of the equipment.

Familiarity with each individual component’s role and placement is an essential step in mastering machine maintenance. With a well-organized reference, users can pinpoint the cause of issues quickly and execute solutions with confidence, leading to better results and less downtime.

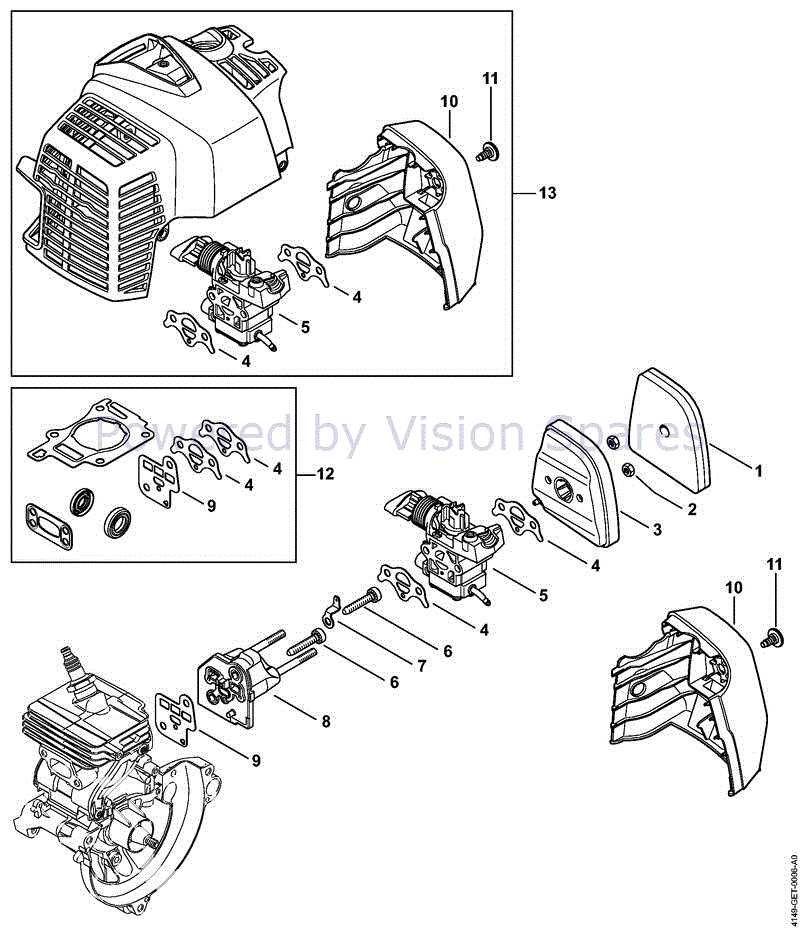

Understanding the FS94R Parts Layout

Efficient equipment maintenance begins with a clear understanding of its internal components. A well-organized overview allows users to recognize the essential elements that make up the machine, helping to identify any potential areas of concern. A systematic approach to visualizing the structure aids in pinpointing key areas quickly during troubleshooting or when performing repairs.

Each section of the machine serves a specific function, and understanding the arrangement of these parts enhances overall performance. Recognizing how each element fits together can reveal insights into the machine’s operations and simplify the repair process. Familiarity with the configuration supports users in making informed decisions about maintenance tasks and adjustments.

By studying a detailed layout, users can better anticipate common issues and act swiftly to resolve them. This understanding is crucial not only for troubleshooting but also for preventing wear and ensuring long-term reliability. A comprehensive view of the machine’s makeup provides users with the knowledge needed to maintain optimal performance.

Key Components of the FS94R Model

To fully comprehend how a machine operates, it is essential to examine its core components. These elements work together to ensure smooth functionality and efficient performance. Understanding their individual roles and interconnections can help users maintain the equipment more effectively and troubleshoot issues with ease.

Critical sections such as the engine, control mechanisms, and operational attachments are integral to the machine’s overall effectiveness. Each part plays a specific role, whether it’s enabling power delivery, controlling movement, or ensuring safe and precise handling during use. A solid grasp of these components allows users to understand how the system functions as a whole.

Knowledge of the main sections not only aids in repair and maintenance but also helps with preventive care. Regularly inspecting these key elements can help avoid wear and tear, leading to longer-lasting performance and fewer disruptions. Identifying any faulty or degraded parts early ensures the equipment stays in optimal working condition.

How to Use the FS94R Diagram for Repairs

When it comes to maintaining and repairing machinery, having a clear visual reference is crucial. A detailed layout of the system’s components can guide users through the repair process, making it easier to identify issues and perform the necessary fixes. By understanding how each element is interconnected, users can troubleshoot effectively and address problems quickly.

To begin, locate the section that corresponds to the area of concern. Carefully study the positions of the various components and note any parts that appear damaged or worn. Precise identification of faulty sections is key to preventing unnecessary disassembly and focusing only on the areas that require attention.

Once the issue is identified, refer to the diagram to understand the assembly process. Knowing how the parts are arranged and connected will help in reassembling the machine correctly after the repair. By following the reference guide step by step, users can ensure that every component is properly aligned, avoiding mistakes that could lead to further complications.